- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

497

-

Product name:

-

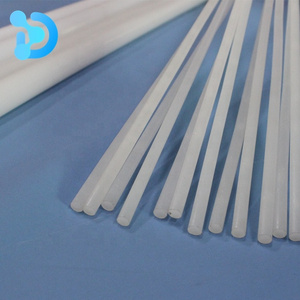

PCTFE ROD

-

Material:

-

PC 100% Virgin Material

-

Color:

-

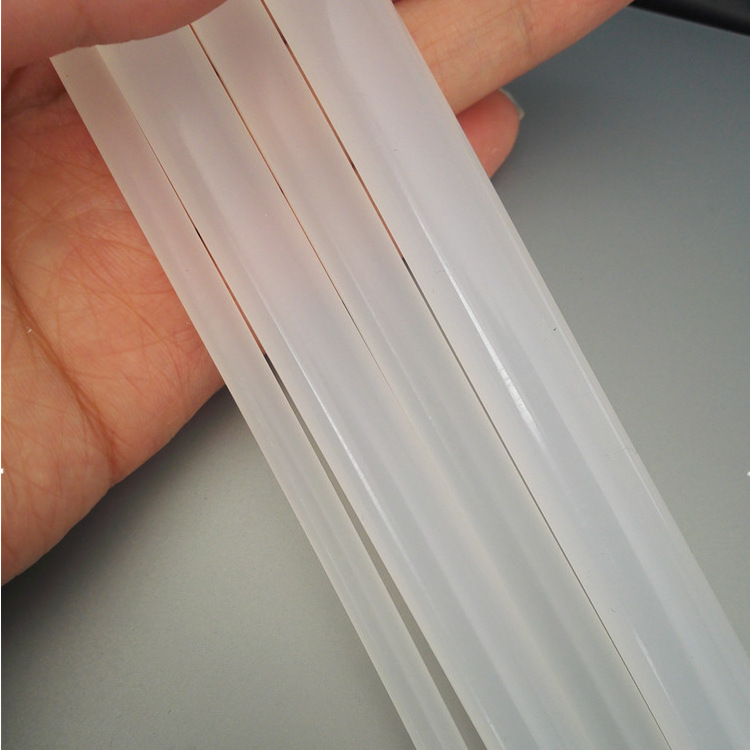

Transparent

-

Size:

-

Costomized

-

Outer diameter dimensions:

-

3--100MM

-

Certificate:

-

ISO9001

-

Hardness:

-

M75

-

yieldly:

-

GUANGDONG CHINA

-

MOQ:

-

50KG

-

Keyword:

-

PC RODS

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

NAXILAI

-

Model Number:

-

497

-

Product name:

-

PCTFE ROD

-

Material:

-

PC 100% Virgin Material

-

Color:

-

Transparent

-

Size:

-

Costomized

-

Outer diameter dimensions:

-

3--100MM

-

Certificate:

-

ISO9001

-

Hardness:

-

M75

-

yieldly:

-

GUANGDONG CHINA

-

MOQ:

-

50KG

-

Keyword:

-

PC RODS

NAXILAI PCTFE ROD

| PRODUCT INFORMATION | |

| brand |

NAXILAI |

| Mouding technics | Extruded |

| Density | 1.2g/cm3 |

|

Surface Finished |

Smooth |

|

Gravity |

1.2 g/cm3 |

|

MOQ |

50KG |

| Packing | As per export package by factory |

| OEM | Welcome |

|

Terms of payment |

L/C,D/P,TT,Western Union,Paypal. |

Product description

PCTFE is inert to most active chemicals at room temperature

The basic properties of PCTFE depend not only on its molecular structure, but also on its molecular quantity and crystalli zation.

1. Mechanical properties

At room temperature,PCTFE mechanical properties are better than PTFE. PCTFE has large compressive strength, small cold flow, large compression resilience and good elastic resilience. However, because PCTFE is a crystalline polymer, its mechanical properties are greatly affected by temperature, and there are also some differences due to the crystallinity and molecular quantity. Sudden cooling during molding can form transparent products with low crystallinity; slow cooling can form translucent products with high crystallinity. In general, the tensile strength and hardness will increase with more crystallization, but the elongation will decrease

2. Thermal performance

PCTFE thermal melting temperature is 211-216 ℃, and the glass state temperature is 71-99 ° C. At 250 ° C, PCTFE can still maintain good thermal stability. But crystallization starts at 130 ° C, and at 160-200 ° C the crystallization speed is the fastest.While crystallization increase, the brittleness gradually increases. Therefore, its long-time working temperature should be kept below 130 ° C; If the use temperature exceeds 200 ° C, it will gradually decompose and be damaged.

3. Low temperature resistance

No embrittlement and creep happen in liquid nitrogen, liquid oxygen and liquefied natural gas, and it can be used at - 273 ° C under certain conditions .

4. Corrosion resistance

High fluorine content makes PCTFE resistant to almost all chemicals and oxidants. It can be immersed in acid, alkali or oxidant for a long time without any change. It can only be corroded by molten alkali metal, fluorine element and chlorine trifluoride at high temperature, and will swell when contacting benzene and its homologues and polyhalides at high temperature.

5,Permeability

Among all plastics, PCTFE has the lowest water vapor permeability and is impervious to any gas. It is a good barrier polymer.

6. Electrical performance

In terms of electrical properties, the dielectric constant and dielectric loss factor of PCTFE are relatively small in a wide frequency range. The electrical properties such as insulation resistance and dielectric breakdown voltage are excellent, and are almost not affected by temperature or humidity. PCTFE is a high-frequency insulation material that can withstand harsh conditions much more than traditional materials.

7. Optical performance

PCTFE has excellent optical performance. The 3mm thick PCTFE plastic sheet is optically transparent μ M-thick film can penetrate 1-4 μ M muscle infrared light 95%, its ultraviolet light absorption rate is also very low.

8. Weather resistance

PCTFE also has good weather resistance, and its performance will not be affected if it is exposed to outdoor sunlight for one year.

Why choose us ?