- Product Details

- {{item.text}}

Quick Details

-

RAL Color:

-

red

-

Hardness:

-

Full Hard

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Wanjintong

-

Application:

-

Roofing Sheet

-

Product name:

-

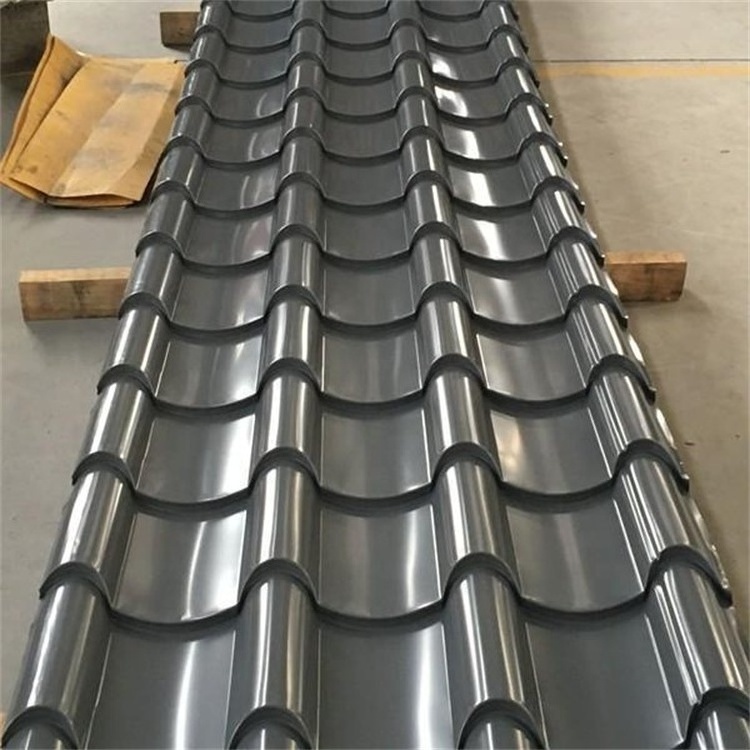

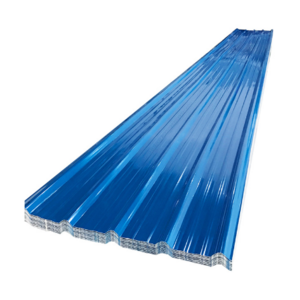

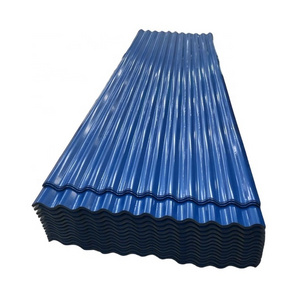

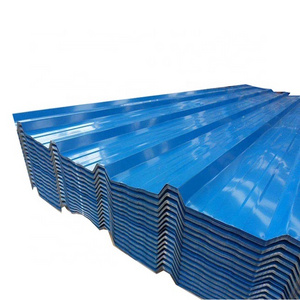

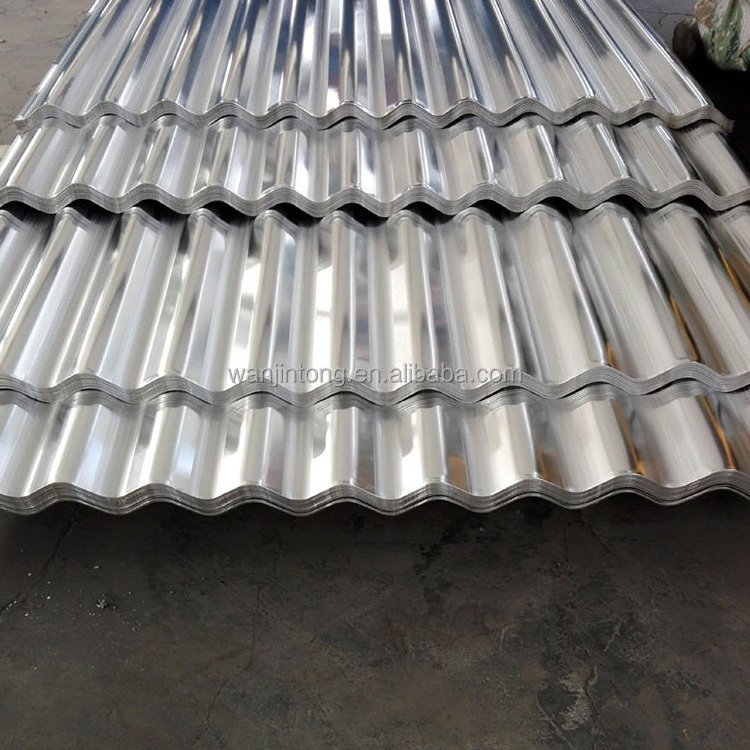

Color Coated Steel Roofing Sheet

-

Keyword:

-

Roof Corrugated Sheet

-

MOQ:

-

1 Ton

-

Color:

-

Custmoized

-

PRICE TERM:

-

FOB CIF CFR EXW

-

Sample:

-

Sample Freely

-

PAYMENT:

-

T/T30% Deposit+70% Advance

-

Quality:

-

High-quality

-

Advantage:

-

Super Anti-corrosion.Beautiful Appearance

Quick Details

-

Thickness:

-

0.26-0.30MM

-

Grade:

-

SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/

-

Coating:

-

Z61-Z90

-

RAL Color:

-

red

-

Hardness:

-

Full Hard

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Wanjintong

-

Application:

-

Roofing Sheet

-

Product name:

-

Color Coated Steel Roofing Sheet

-

Keyword:

-

Roof Corrugated Sheet

-

MOQ:

-

1 Ton

-

Color:

-

Custmoized

-

PRICE TERM:

-

FOB CIF CFR EXW

-

Sample:

-

Sample Freely

-

PAYMENT:

-

T/T30% Deposit+70% Advance

-

Quality:

-

High-quality

-

Advantage:

-

Super Anti-corrosion.Beautiful Appearance

Color-coated Galvanized steel

Popular science knowledge

Cold Rolled Substrate Color Coated Steel Plate

The color plate produced from the cold-rolled substrate has a smooth and beautiful appearance and has the processability of cold-rolled plate; however, any small scratches in the surface coating will expose the cold-rolled substrate to the air, which will quickly expose the iron to the Generates red rust. Therefore, such products can only be used for temporary isolation measures and interior materials with low requirements.

Hot-dip galvanized color coated steel sheet

The product obtained by coating the organic coating on the hot-dip galvanized steel sheet is the hot-dip galvanized color-coated sheet. In addition to the protection of zinc, the organic coating on the surface of the hot-dip galvanized color-coated sheet also plays the role of insulation and protection, preventing rust, and the service life is longer than that of the hot-dip galvanized sheet.

Hot-dip galvanized color-coated sheet

On request, hot-dip galvanized steel sheets can also be used as color-coated substrates (55% AI-Zn and 5% AI-Zn).

Electro-galvanized color-coated sheet

The electro-galvanized sheet is used as the substrate, and the product obtained by coating the organic paint and baking is the electro-galvanized color-coated sheet. Because the zinc layer of the electro-galvanized sheet is thin, the zinc content of the electro-galvanized sheet is usually 20g/m², so this product is not suitable for use. Make walls, roofs, etc. outdoors.

But because of its beautiful appearance and excellent processing performance,

it can be mainly used in home appliances, audio, steel furniture, interior decoration, etc.

Galvanized details

About Fingerprint Resistant Board

In the production process of home appliances, many parts are touched by workers for many times due to the needs of the process, and the sweat stains on the hands of the workers form pollution on the surface of the parts, which affects the appearance. Therefore, a fingerprint-resistant board has been researched and developed.

Fingerprint-resistant sheet is a composite coated sheet obtained by fingerprint-resistant treatment on the surface of galvanized sheet. Fingerprint-resistant steel plate is a material that has passed environmental protection certification earlier. Because the surface is touched with clean fingers, it will not leave fingerprints, so it is named "fingerprint-resistant". The surface of fingerprint-resistant steel plate is smooth, flat, and small tolerance.

About colors

1. Good plasticity and machinability make it a material for architectural modeling

2. Has good gloss and smoothness, as well as excellent texture and feel

3. According to customer needs, customized according to the picture.

The difference between galvanized sheet and galvanized sheet:

The main difference is the difference in the coating. The surface of the galvanized sheet is evenly distributed with a layer of zinc, which acts as an anodic protection for the base metal and is resistant to corrosion.

The surface coating of the galvanized sheet is composed of 55% aluminum, 43.5% zinc and a small amount of other elements. The surface of the galvanized coating is a honeycomb structure at the microscopic level. The "honeycomb" composed of aluminum contains zinc. Plays the role of anode protection and is more resistant to corrosion.

↑↑

↑↑

↑↑

Both sheets are available

↑↑

↑↑

↑↑

|

Product Details

|

|

|

|

Coating

|

Zinc(Z)+Aluminum(A)/AZ+Si

|

|

|

Coating thickness

|

10μm-100μm

|

|

|

Color

|

Custom made

|

|

|

Thickness

|

0.2mm~3mm

|

|

|

Length

|

sheets≤12000mm,roils No limit

|

|

|

Width

|

20mm~1250mm,or custom made

|

|

|

Supply Ability

|

20 tons per day

|

|

|

Application

|

Indoor and outdoor decoration, home appliances, electronic products, auto parts,etc.

|

|

Workshop & Factory

First step

Pre-treatment:

After the cold-rolled coil arrives in the galvanizing workshop, after passing through the uncoiler, through the degreasing section and the reduction furnace, the steel coil is cleaned and its components are reduced to the extent that it can be galvanized.

Central section:

The most critical technology is this step. After passing through the zinc pot, a layer of zinc is plated on the surface of the steel plate. After coming out of the zinc pot, it is immediately beautiful and atmospheric, and then it is cooled and shaped by the cooling tower, and Cinderella becomes Beautiful princess.

third step

Post-processing:

After a variety of processes, the steel plate finally comes to the post-processing stage. After finishing, straightening, and passivation, it is finally rolled onto the winder to form our final product.

Support the machining process

Processing items:

slitting, flat plate, wire drawing, sandblasting, anodizing, laminating, laser cutting, bending, spraying, electroplating.

Product packaging

Sheet packaging as shown:

All products can be issued with

“Material Quality Assurance”

,

which is provided with the goods.

Coil packaging as shown:

1. Stable delivery time

Our plant large-scale production,

aluminum 500tons supply capacity is very strong,

very much shipments, delivery is very fast.

2. Issued product quality standards

From the material accessories selection, manufacturing paint links,

to the installation and commissioning, repeated experiments,

layers of quality control, to ensure that qualified products

3. Traffic conditions are very convenient

We are located in the transport hub,

land transport, water transport, shipping conditions are very convenient

to ensure that transport costs are reasonable, adequate transport time.

4. Product packaging material selection, good protection products

Finished China manufacturer products immediately outside the anti-rust treatment,

and the use of plastic packaging for further protection, delivery using thick wood, steel frame protection,

and other diversified packaging conditions to ensure that products in the long sea is not affected.

FAQ

Whether to provide quality assurance and complete after-sales support?

Yes!

If there are quality problems (such as bubbles,sand holes,etc),or the size does not match the order.commitment to return the goods,the freight is borne by the shop,you can rest assured to place an order.

Is it possible to deliver in time?

Yes!

Our manufactory is very high degree of modernization, brand positioning the global market, production capacity is very strong, conventional styles try to ensure that the spot.

Whether to support OEM services, custom processing?

Yes!

We have always been in the principle of customer first,

you can design and provide a set of solutions.

Is it possible to visit your factory? Is the traffic convenient?

Yes!

Our factory is located in China's Shandong Province,Liaocheng City,Land, sea and air traffic conditions are very convenient.

Is the sample free?

Yes!

We provides FREE SAMPLES,NO MOQ,and the postage needs to be paid by yourself. If the customer specifies the cutting aluminum sample,the cost of production will be calculated,but the bulk order can be deducted.

Aluminum has thickness,length,width,and processing tolerances,and after cutting and transportation,it may be scratched(scratches).if you have strict requirements,please communicate and confirm with customer service in advance.

Hot Searches