- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

product name:

-

Custom Plastic Cover

-

Color:

-

Customer Request

-

Feature:

-

Eco-friendly

-

Usage:

-

Pollen tray

-

Size:

-

Customised Accept

-

Certificate:

-

ISO9001:2008

-

Product name:

-

Pollen tray

-

Thickness:

-

1.2-1.5mm

-

Application:

-

pollen tray

Quick Details

-

Material:

-

Plastic

-

Shape:

-

Transparent

-

Style:

-

modern

-

Place of Origin:

-

Guangdong, China

-

product name:

-

Custom Plastic Cover

-

Color:

-

Customer Request

-

Feature:

-

Eco-friendly

-

Usage:

-

Pollen tray

-

Size:

-

Customised Accept

-

Certificate:

-

ISO9001:2008

-

Product name:

-

Pollen tray

-

Thickness:

-

1.2-1.5mm

-

Application:

-

pollen tray

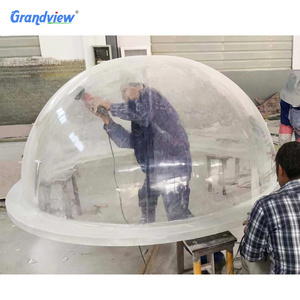

PVC/Acrylic PET /PETG/PC Vacuum forming transparent plastic lamp cover

The following are our main products, we can also customize products according to customer's demands.

Product Description

|

Products Name |

transparent plastic cover plastic lamp cover |

|

Model |

B005 |

|

Material |

PC |

|

Thickness |

3mm |

|

Color |

Black as Customer's requirements |

|

Size |

490*300*50mm |

|

weight |

N.W:0.5KG G.W:1KG |

|

LOGO |

You can choose what you want |

|

Packing Details |

Safe Export carton box :540*350*100mm |

|

Process |

Vacuum forming+ CNC cutting the side, assemble and install |

|

Usage |

Leisure and entertainment,Fishing |

|

MOQ |

500pcs,Sample order is acceptable |

|

Delivery Time |

About 15 days for sample order and 45 days for mass production. |

|

Payment Term |

Samples order 100% payment before production. Mass production order 50% deposit, 50% balance payment before shipment. |

|

Advantage |

1.2016 New design , advantage technology |

|

2. The raw materials production, stable quality. |

|

|

3. Advanced high-tech machinery and equipment. |

|

|

4.Prompt delivery. |

|

|

5.Satisfactory pre-sale service & after-sale servi |

More picture detail

High quality PC plastic cover custom vacuum forming plastic parts for cover can’t be produced without reliable manufacturing tools and effective production process. We will purchase the high quality raw materials and put them into production.

Firstly, using the latest technology, we heat to a high temperature to make the materials softening with the large vacuum forming machines and the moulds. Secondly, some air will be injected to swell the materials up ,then we pump out the air so that the materials can form products on the mold in a vacuum environment. At last, we have to cut, polish and color the products.

Our production pattern can effectively control the quality, cost and time, and save maximally the cost of customers and shorten the production cycle.