- Product Details

- {{item.text}}

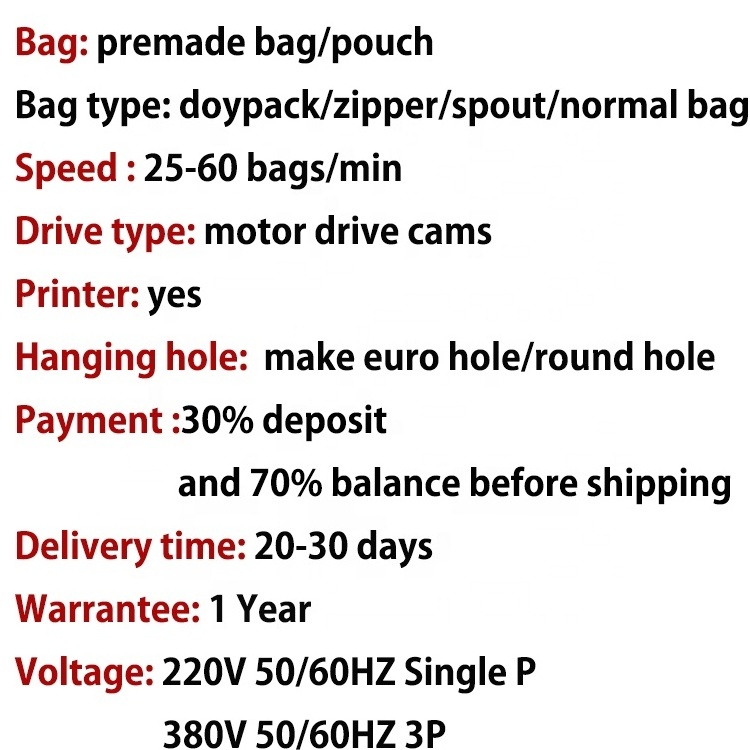

Quick Details

-

Production Capacity:

-

40-60 bag/min

-

Weight (KG):

-

1400

-

Voltage:

-

380V 50/60 HZ 3P

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LINTYCO

-

Dimension(L*W*H):

-

2700*1660*1720MM

-

Bag film material:

-

Premade laminated Film bag;aluminum foil bag:Paper bag

-

Machine:

-

Food grade SS304/316

-

EOM:

-

Yes.

-

Bag type:

-

Zipper Bag,Stand up Bag,Doypack,Spout Bag

-

Delivery time:

-

20-60 days

-

Speed:

-

20-60 bag/min

-

Machine function:

-

Bag feed,Date print,fill and seal. Vacuum function,nitrogen flush

-

Payment:

-

T/T 30% and 70% or T/T 40% and 60%

-

Advantage:

-

machine making process track service and video call hand by hand guide

-

After-sales Service Provided:

-

Video call directly hand by hand guide and video/drawing specification

Quick Details

-

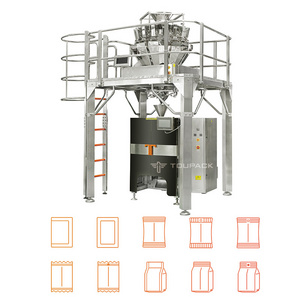

Function:

-

FILLING, Labeling, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Pouch, Zipper Bag

-

Packaging Material:

-

Plastic, paper laminated plastic

-

Production Capacity:

-

40-60 bag/min

-

Weight (KG):

-

1400

-

Voltage:

-

380V 50/60 HZ 3P

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LINTYCO

-

Dimension(L*W*H):

-

2700*1660*1720MM

-

Bag film material:

-

Premade laminated Film bag;aluminum foil bag:Paper bag

-

Machine:

-

Food grade SS304/316

-

EOM:

-

Yes.

-

Bag type:

-

Zipper Bag,Stand up Bag,Doypack,Spout Bag

-

Delivery time:

-

20-60 days

-

Speed:

-

20-60 bag/min

-

Machine function:

-

Bag feed,Date print,fill and seal. Vacuum function,nitrogen flush

-

Payment:

-

T/T 30% and 70% or T/T 40% and 60%

-

Advantage:

-

machine making process track service and video call hand by hand guide

-

After-sales Service Provided:

-

Video call directly hand by hand guide and video/drawing specification

|

Summery

|

|

|

|

|

|||

|

1.Easy to change bag size and bag type.

2.Easy to adjust Printer range. 3.Machine optoelectronic system can check bag,material filling and sealing situation to avoid failure. 4.Stable worktable with low noise and long life as the bottom drive system. 5.High bag opening effective and low machine failure rate. 6.Sample wiring arrangement with high quality electronic components |

|

|

|

|

|||

|

Parameters

|

|

|

|

|

|||

|

Model

|

LTC8-200

|

LTC8-260

|

LTC8-300

|

LTC8-400

|

|||

|

Bags size

|

W:80~210mm L:100~300mm

|

W:140~260mm L:100~400mm

|

W:200~300mm L:100~400mm

|

W:300~400mm L:100~450mm

|

|||

|

Bag type

|

Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag

|

Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag

|

Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag

|

Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag

|

|||

|

Filling Volume

|

30 – 1900g

|

30-2000g

|

100-2500g

|

100-5000g

|

|||

|

Capacity

|

25-60 bags/min for different material and different bag

|

25-60 bags/min for different material and different bag

|

25-60 bags/min for different material and different bag

|

10-40 bags/min

|

|||

|

Dimension

|

1.140*1.500*1.560m

|

2.46*1.83*1.46m

|

|

customize made

|

|||

|

Weight & power supply

|

1400kgs/1500kgs/1600kgs-1800kgs 380v 50HZ 3P 2.5kw-5kw

|

|

|

|

|||

|

Compress air requirement

|

0.6-1m³/min supply by user

|

|

|

|

|||

|

Working flow

|

1. Bag feeding

2. Date printing 3. Zipper opening 4. Bag opening 5. Material filling 6. 2th material filling 7. Buffering or function 8. 2th sealing and output |

|

|

|

|||

Hot Searches