- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

70 kN

-

Theoretical Shot Volume(cm³):

-

608 cm³

-

Injection Rate (g/s):

-

106 g/s

-

Injection Weight (g):

-

200 g

-

Screw diameter (mm):

-

40 mm

-

Screw L/D Ratio:

-

25

-

Distance between Tie Bars:

-

765*765

-

Weight (KG):

-

3800

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

740 mm

-

Model Number:

-

TIE

-

Brand Name:

-

Crown Machinery

-

Power (kW):

-

13 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

Product name:

-

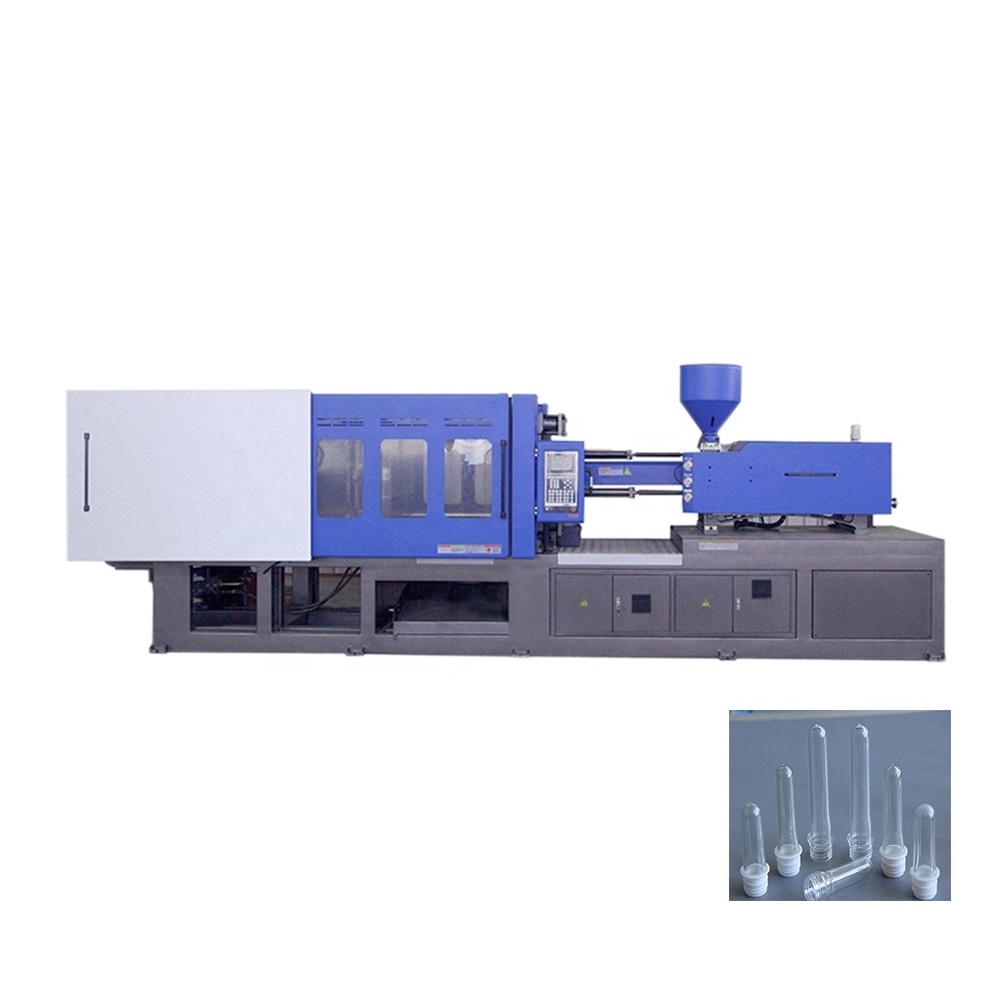

Plastic Injection Moulding Machine

-

Machine dimension(L*W*H):

-

4.78*1.19*1.98m

-

Screw diameter:

-

38/40/45mm

-

SCREW L/D RATIO:

-

22.1/21/18.7

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

-

Heating power:

-

9.5kW

-

MOULD THICKNESS:

-

150-450mm

-

Ejector Stroke:

-

130mm

-

Certification:

-

CE,ISO9001

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

510mm

-

Distance between Tie Bars(Height)(mm):

-

510mm

-

Ejector Stroke(mm):

-

155 mm

-

Ejector Force(kN):

-

70 kN

-

Theoretical Shot Volume(cm³):

-

608 cm³

-

Injection Rate (g/s):

-

106 g/s

-

Injection Weight (g):

-

200 g

-

Screw diameter (mm):

-

40 mm

-

Screw L/D Ratio:

-

25

-

Distance between Tie Bars:

-

765*765

-

Weight (KG):

-

3800

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

740 mm

-

Model Number:

-

TIE

-

Brand Name:

-

Crown Machinery

-

Power (kW):

-

13 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

Product name:

-

Plastic Injection Moulding Machine

-

Machine dimension(L*W*H):

-

4.78*1.19*1.98m

-

Screw diameter:

-

38/40/45mm

-

SCREW L/D RATIO:

-

22.1/21/18.7

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

-

Heating power:

-

9.5kW

-

MOULD THICKNESS:

-

150-450mm

-

Ejector Stroke:

-

130mm

-

Certification:

-

CE,ISO9001

Product Description

Product Performance

* Strong rigidity of the template and Stable operation

* The optimized front joint connecting rod adopts integral casting, which has good rigidity and stable operation.

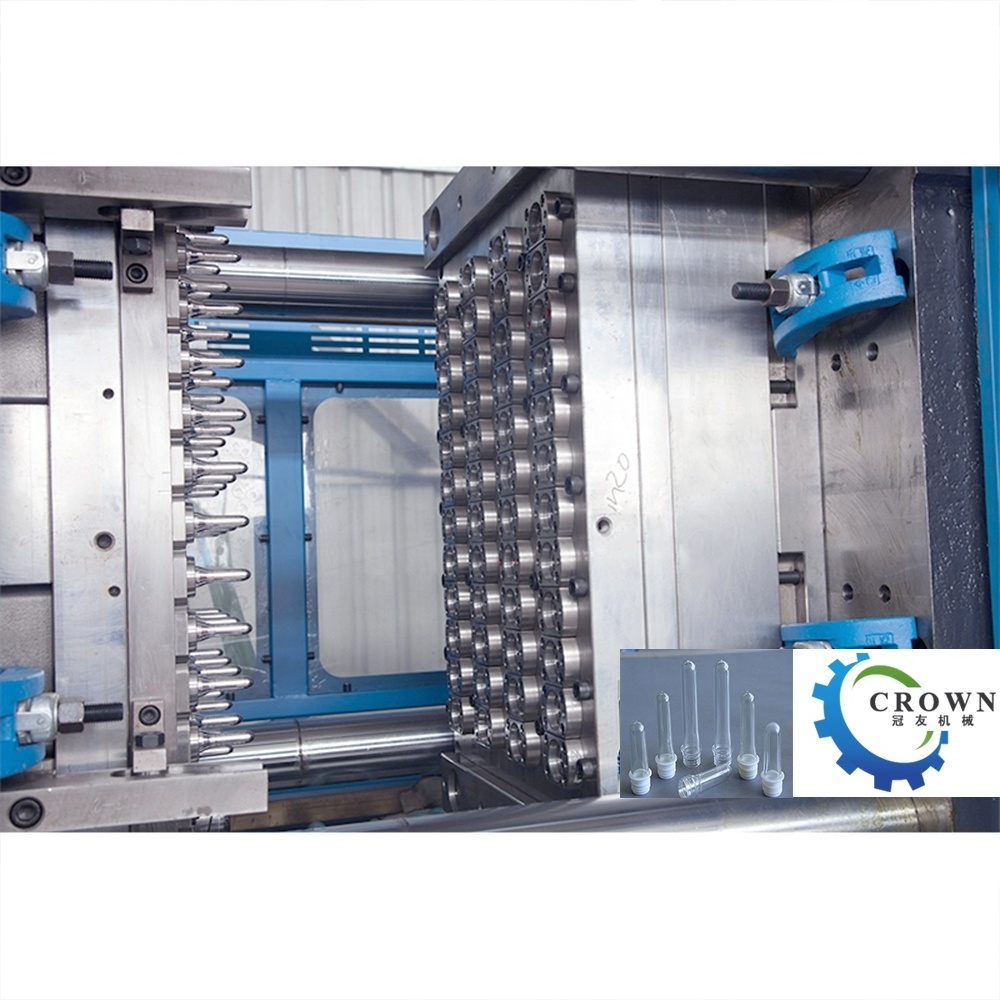

* The railings and guides are made of aluminum/copper sleeves or self-lubricating guide sleeves, which have a special wear resistance and low friction coefficient.it dramatically increases the life service of the draw bar.

* The template adopts a structure in which a T-shaped groove and a mounting screw coexist. Reasonable T-slot layout not only facilitates the installation of the mold, but also increases the strength of the template.

* The Tie rods of each model are tested by the most professional inspection mechanism to ensure that the deformation of the tie rods is within a reasonable range when the machine is in operation.

* The optimized front joint connecting rod adopts integral casting, which has good rigidity and stable operation.

* The railings and guides are made of aluminum/copper sleeves or self-lubricating guide sleeves, which have a special wear resistance and low friction coefficient.it dramatically increases the life service of the draw bar.

* The template adopts a structure in which a T-shaped groove and a mounting screw coexist. Reasonable T-slot layout not only facilitates the installation of the mold, but also increases the strength of the template.

* The Tie rods of each model are tested by the most professional inspection mechanism to ensure that the deformation of the tie rods is within a reasonable range when the machine is in operation.

|

Model

|

TIE-1600A

|

|

|

TIE-2400A

|

|

|

TIE-4800A

|

|

|

||||||

|

Plasticizing Capacity(g/s)

|

20.1

|

26.5

|

34.2

|

26.4

|

32.5

|

40

|

60.4

|

71.4

|

83.7

|

||||||

|

Motor Power(kw)

|

15

|

|

|

22

|

|

|

45

|

|

|

||||||

|

Pump Pressure (Mpa)

|

16

|

|

|

16

|

|

|

16

|

|

|

||||||

|

Heating Power(kw)

|

13.6

|

|

|

18.5

|

|

|

28

|

|

|

||||||

|

Heating Zone

|

4

|

|

|

5

|

|

|

5

|

|

|

||||||

|

Overall Size(mm)

|

5300*1350*1900

|

|

|

6200*1600*2100

|

|

|

7500*2100*2450

|

|

|

||||||

|

Net Weight(T)

|

5.6

|

|

|

8.0

|

|

|

20

|

|

|

||||||

|

Oil Tank Capacity(L)

|

420

|

|

|

440

|

|

|

850

|

|

|

||||||

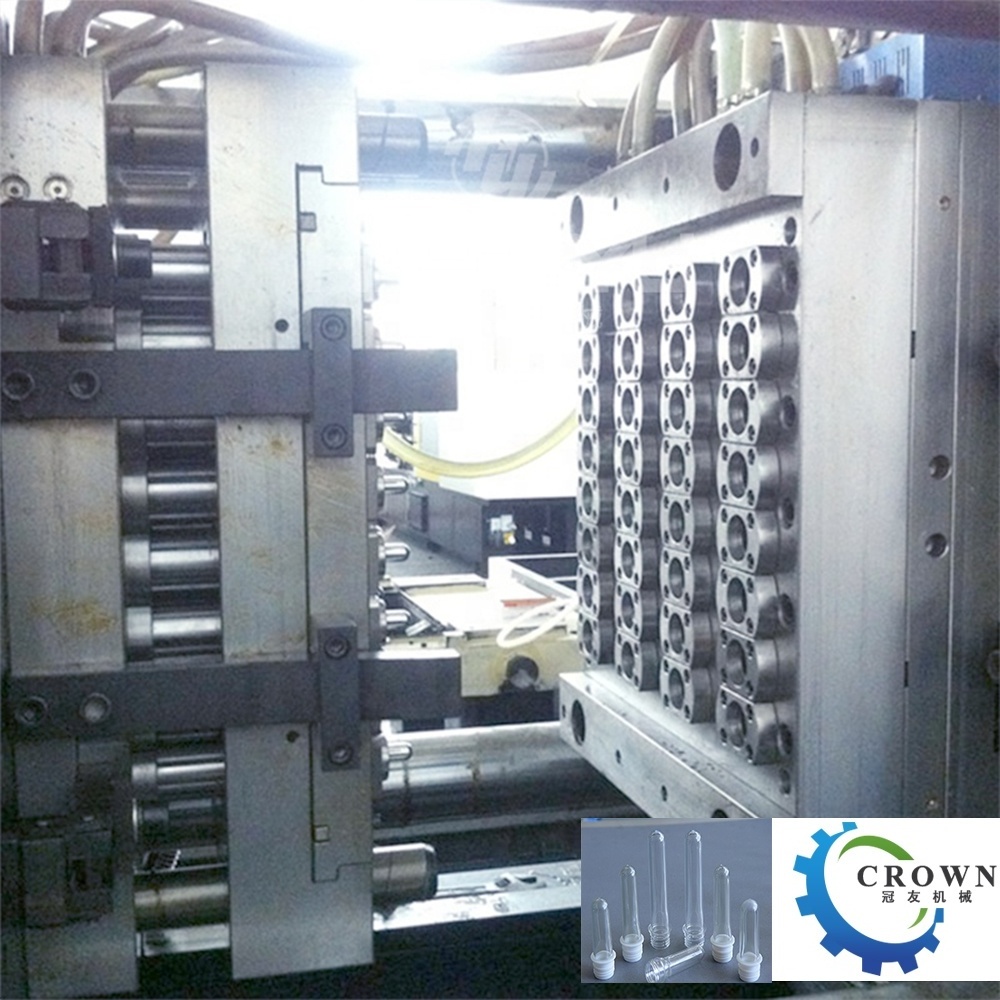

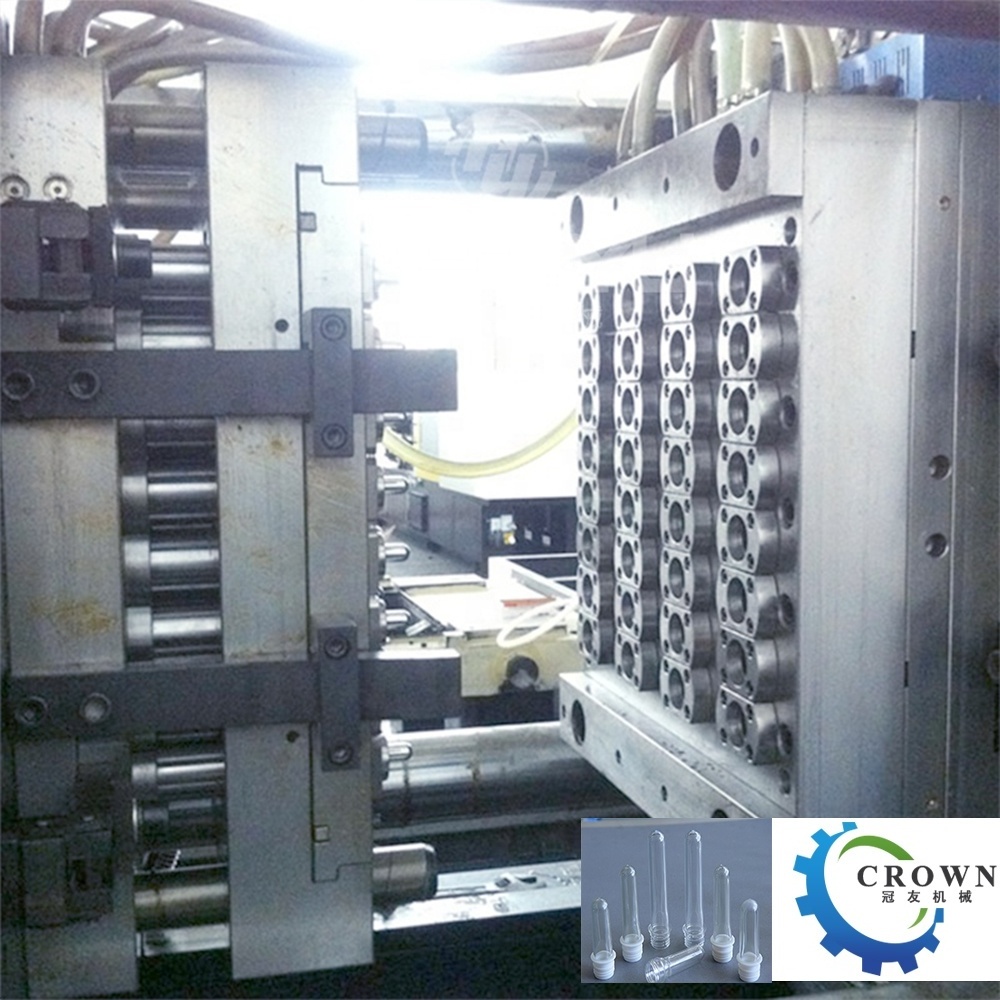

Detailed Images

Related Products

Packing&Shipping

Company Introduction

Crown Customers,Crown Friends

After Sales Service

FAQ

Hot Searches