- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Feininger

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

20X4mX6m

-

Weight:

-

15 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Foaming Agent:

-

Pentane

-

Output:

-

400-2000 kg/hr

-

Diameter of Beads:

-

0.6-2.0

-

Automatic Grade:

-

Automatic

-

Power:

-

90KW--325KW

-

Service Provided:

-

Video technical support

-

After-sales Service:

-

Field installation, commissioning and training

-

After Service Provided:

-

Field maintenance and repair service

-

Marketing Type:

-

New Product 2020

Quick Details

-

Screw Design:

-

Double-screw

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Feininger

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

20X4mX6m

-

Weight:

-

15 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Foaming Agent:

-

Pentane

-

Output:

-

400-2000 kg/hr

-

Diameter of Beads:

-

0.6-2.0

-

Automatic Grade:

-

Automatic

-

Power:

-

90KW--325KW

-

Service Provided:

-

Video technical support

-

After-sales Service:

-

Field installation, commissioning and training

-

After Service Provided:

-

Field maintenance and repair service

-

Marketing Type:

-

New Product 2020

Product Description

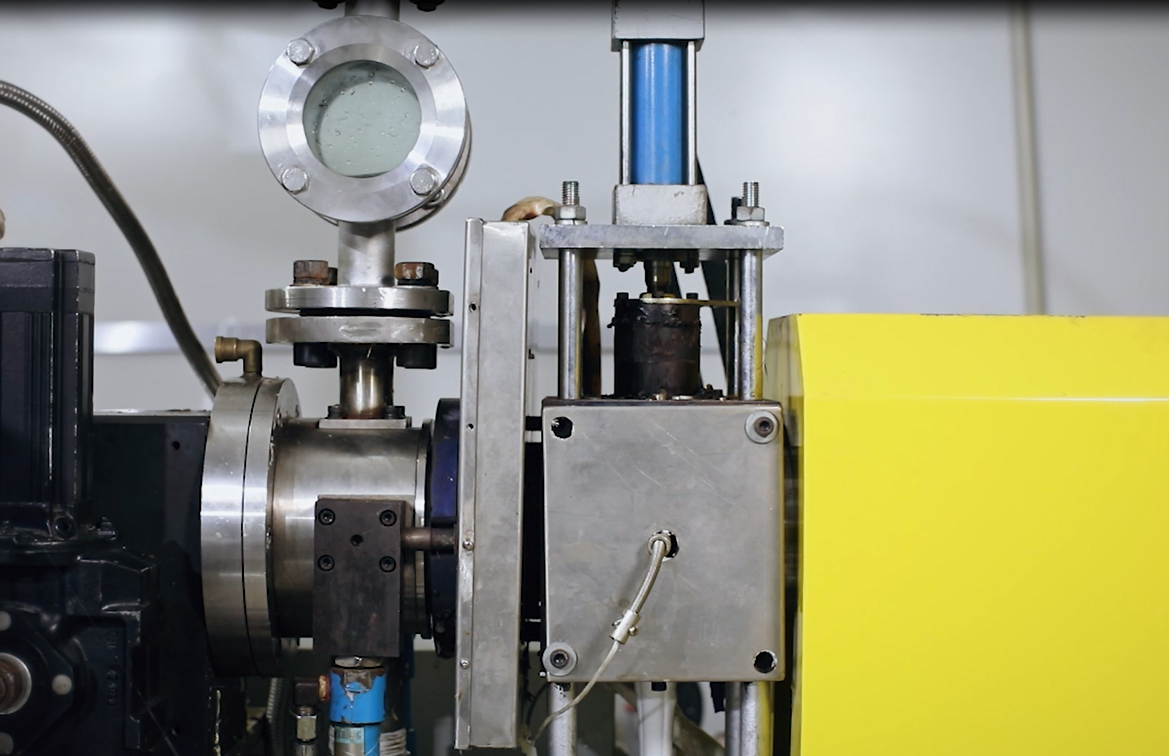

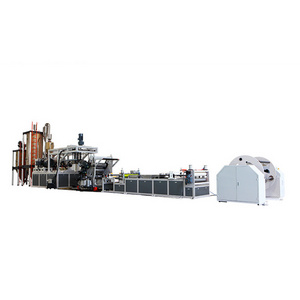

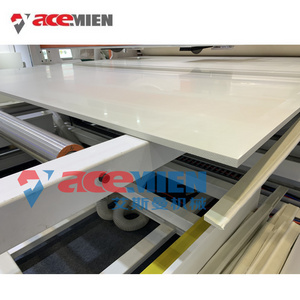

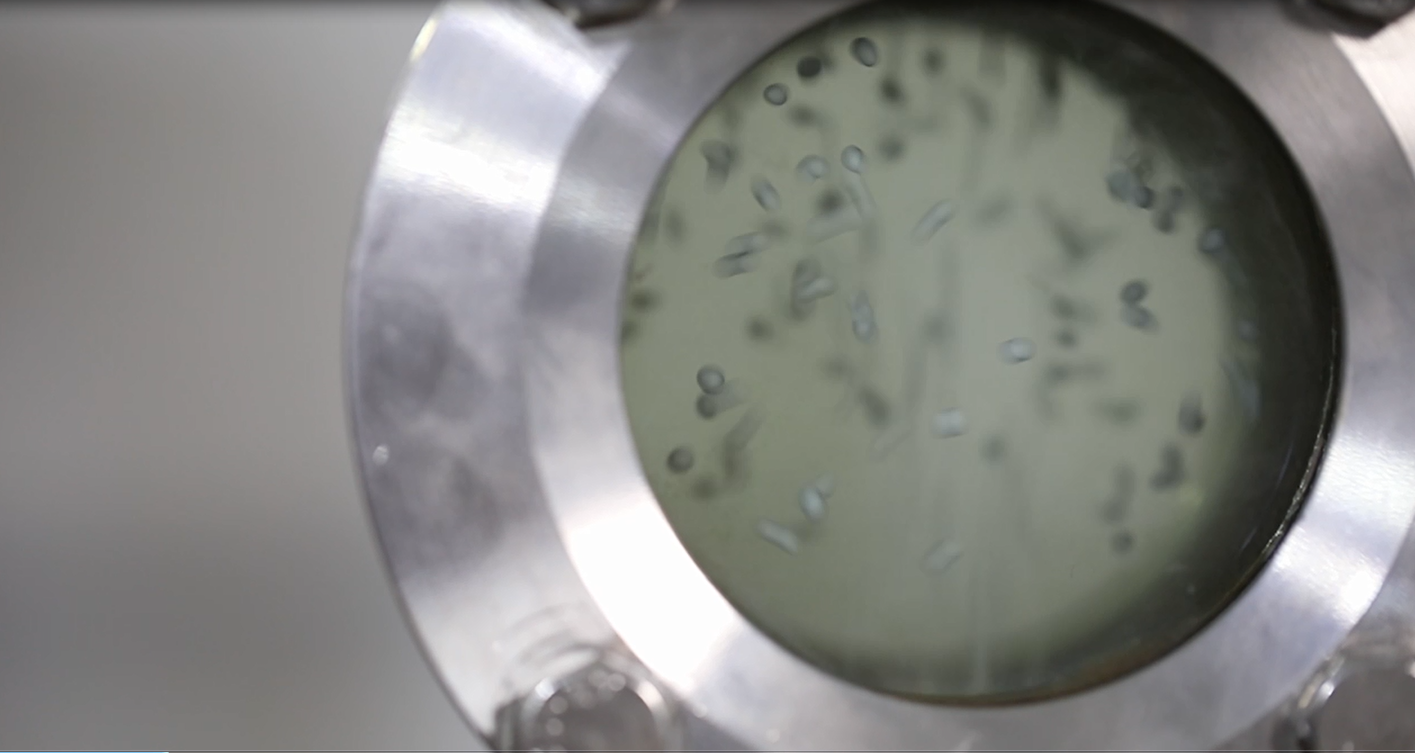

ETPU Beads Extrusion Production Line / ETPU Middle Sole Shoe Making Foaming Machine

Fein

i

nger extrusion ETPU production line, mature process, high equipment stability.The technology of supercritical CO2 fluid kettle pressure foaming and the new technology of pressure compensation solved the problem that polyester ETPU is easy to hydrolyze and yellowing in the application stage in the industry.

Specification

|

Model NO.

|

ES-95T

|

|

Screw

|

Twin-Screw

|

|

Automation

|

Automatic

|

|

Assembly Structure

|

Integral Type Extruder

|

|

Engagement System

|

Intermeshing

|

|

Origin

|

China Feininger

|

Basic Configuration

1. TPU Drying System

2. Raw Material Conveying and Feeding System

3. Twin Screw Extruder

4. Foam Agent Injection System

5. Nucleating Agent System

6. Underwater Pelletizing System

7. Vibration Drying System

8. Electrical Control Cabinet

2. Raw Material Conveying and Feeding System

3. Twin Screw Extruder

4. Foam Agent Injection System

5. Nucleating Agent System

6. Underwater Pelletizing System

7. Vibration Drying System

8. Electrical Control Cabinet

Optional Equipment

1.Coating material mix machine

2.Finished product tank

3.Automatic packing system

Hot Searches