- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

90KW

-

Dimension(L*W*H):

-

12*1.5*4m

-

Weight:

-

7500 kg

-

Name:

-

toilet paper rewinding machine

-

Raw material:

-

Waste Paper

-

Output paper:

-

Toilet Paper Tissue Paper Napkin Paper

-

Capacity:

-

2t/d

-

Working speed:

-

50-80m/min

-

Net paper width:

-

787-900mm

-

Output paper weight:

-

13-40g/m2

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Production Capacity:

-

200 m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MEIDA

-

Voltage:

-

380V

-

Power:

-

90KW

-

Dimension(L*W*H):

-

12*1.5*4m

-

Weight:

-

7500 kg

-

Name:

-

toilet paper rewinding machine

-

Raw material:

-

Waste Paper

-

Output paper:

-

Toilet Paper Tissue Paper Napkin Paper

-

Capacity:

-

2t/d

-

Working speed:

-

50-80m/min

-

Net paper width:

-

787-900mm

-

Output paper weight:

-

13-40g/m2

-

After-sales Service Provided:

-

Field installation, commissioning and training

Model 787 toilet paper make machine technical details

1 Technical parameter:

|

1 |

R aw materials |

waste paper, white or brown cellulose ,virgin pulp R aw materials different, whole line price also different |

|

2 |

O utput paper |

toilet paper, tissue paper, facial tissue paper ,kitchen paper etc please tell us your final product is J umboo paper roll or small paper roll ,because different final product need different machines, so whole line price also different |

|

3 |

C apacity |

0.5-1.5 tons per day |

|

4 |

N et paper width |

787-900mm |

|

5 |

O utput paper weight |

13-40 g/m 2 ; |

|

6 |

D iameter of dryer |

1000mm or 1250mm or 1500mm D ryer size depends on buyer’s capacity requirement |

|

7 |

W orking speed |

50-80 m/min; |

|

8 |

The gauge |

1300mm |

|

9 |

Take area |

150m2 |

|

10 |

Drive and control |

gear drive , Alternating current, frequency conversion |

|

11 |

Machine weight |

7500kg |

|

12 |

Machine size |

12*1.5*4m |

|

14 |

Voltage |

380v 50hz 3phase I f need change HZ or voltage, pls inform us in advance |

2 Raw Materails

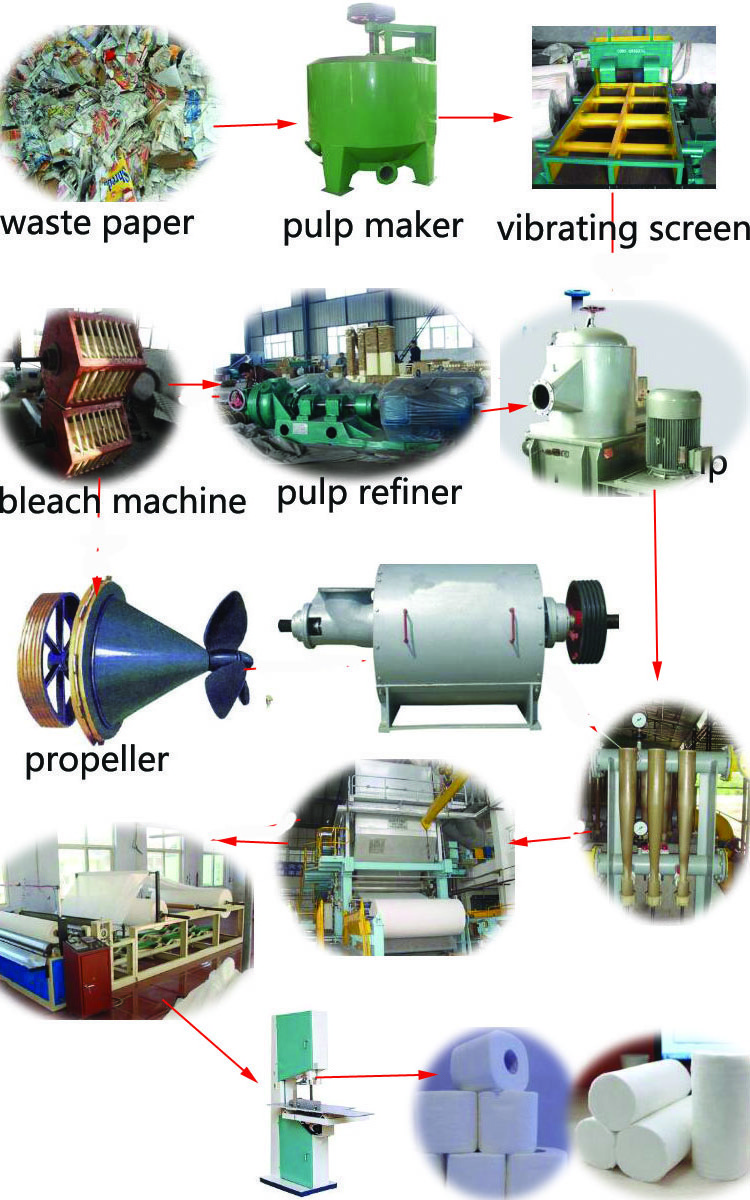

3 Paper making flowchart for Jumboo Paper Roll ( waste paper recycle)

Note: Different raw materials the pulping system will be different

4

Toilet paper rewinder, automatic paper cutter, automatic packaging machine

Toilet paper rewinder, paper cutter

Toilet paper slitting and rewinding machine

Facial tissue paper folding and embossing machine

Napkin folding embossing machine

spare parts of tissue toilet paper making machine

Dryer cylinder,boiler,cylinder mould

Hydrapulper,Vibrating screen,Headbox,Desander,Grinding machine,etc.

Couch roller,Pressure roller,Back roller,Scroll roll, Felt roll,etc.

1 what is the cost of a whole paper production line ?

|

Raw materials |

All these will influnce the whole line cost. What we can tell you is smallest paper production line need a budget around 40,000-50,000 USD include shipping cost to your factory |

|

Daily capacity |

|

|

Finish paper style |

2 daily cost for a whole paper production line

|

M ake one ton paper need chemical |

40-60 usd ( different raw materials chemical cost different ) |

|

M ake one ton paper need water |

A bout 3-5tons , waster can be recycle |

|

E lectricity consume |

D epends on which model machine you bought |

|

Raw materials cost |

Depends on your local raw materials price |

|

Worker cost |

Depends on your local salary |

3 shipping & install cost

|

S hipping cost |

C ontainer quantity * unit container cost from our factory to your sea port ( container quantity depends on which style machine you bought) |

|

I nstall cost & worker training |

W e sent at least 2 engineer to do install for you H is salary & tickets & living etc under buyer ’ s cost S alary is around 2200 usd/month/person. Install time depends on machine size |

4 before you purchase the machine, we can offer

|

1 details quotation |

N eed buyer offer details ( see above buying guide ) |

|

2 layout drawing |

N eed buyer offer factory size |

|

3 meet with you face to face |

W elcome come our factory , you will see running machine . |

|

4 offer detailed document support |

I f you need ask loan with sale contract , we can provide any document for your need |

|

5 other support |

A ny reasonable requriement from you, all can be acceptaed |

|

6 quanlity control |

100% meet your requriement based on sale contract |

5 after sale service

|

1 warrant time |

12 month |

|

2 spare parts |

Y ou can contact the sales 7*24hours if u need any spare parts |

|

3business expand |

I f u need increase your present machine style, we will offer further support by offer technical drawing etc . |

|

4 shipping document |

A ll needed shipping document will provide to you in time for your safty custom clearance |

6 Dear customer, welcome come to zhengzhou for a face to face discuss