The

continuous type and batch type pyrolysis plants

designed by Doing Company’s engineer team have been exported to the United States, the United Kingdom, France, Italy, Australia, Dubai, Brazil, Kazakhstan, Pakistan, India, Nigeria, Mexico, Egypt, Thailand and other

90+

countries and regions. Their outstanding economic and environmental benefits have led the development of the waste tire/plastic/oil sludge/rubber/aluminum plastic composite material pyrolysis industry.

The whole process is safe and environmentally friendly. For details, please contact our professional project manager for consultation.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4*2.5*2.8

-

Year:

-

2020

-

Power (kW):

-

35 kW

-

Weight (KG):

-

35000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

converting waste tyre to fuel oil

-

tire machine type:

-

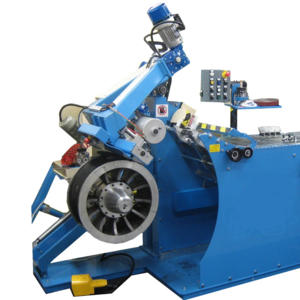

continuous waste plastic pyrolysis plant

-

material of reactor:

-

Q245R

-

thickness:

-

16mm

-

mode of cooling:

-

water cooling

-

quality test:

-

X-ray test for welding crack line

-

quality control:

-

heat treating workship

-

Function:

-

continuous pyrolysis plant

-

Application:

-

continuous waste tyre pyrolysis plant

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DOING

-

Voltage:

-

220V,380V,440V

-

Dimension(L*W*H):

-

4*2.5*2.8

-

Year:

-

2020

-

Power (kW):

-

35 kW

-

Weight (KG):

-

35000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

converting waste tyre to fuel oil

-

tire machine type:

-

continuous waste plastic pyrolysis plant

-

material of reactor:

-

Q245R

-

thickness:

-

16mm

-

mode of cooling:

-

water cooling

-

quality test:

-

X-ray test for welding crack line

-

quality control:

-

heat treating workship

-

Function:

-

continuous pyrolysis plant

-

Application:

-

continuous waste tyre pyrolysis plant

DOING COMPANY PYROLYSIS PANT

Product Paramenters

Scheme 1: small scale free installation pyrolysis plant unit

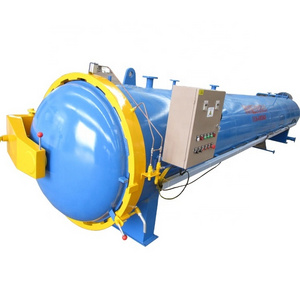

Scheme 2: cost effective batch type pyrolysis plant

|

Items

|

Batch Pyrolysis Plant

|

|

|

||

|

Equipment type

|

DY-1-6

|

DY-1-10

|

DY-1-12

|

||

|

Raw material

|

Waste plastics, tyres

|

Waste plastics, tyres

|

Waste plastics, tyres

|

||

|

Structural form

|

Horizontal rotation

|

Horizontal rotation

|

Horizontal rotation

|

||

|

24-hour Capacity

|

6 ton

|

10 ton

|

12 ton

|

||

|

Oil yield

|

2.7-3.3ton

|

4.5 -5.5ton

|

4.8 -6.6ton

|

||

|

Operating pressure

|

Normal

|

Normal

|

Normal

|

||

|

Material of pyrolysis Reactor

|

Q245R

|

Q245R

|

Q245R

|

||

|

Thickness of pyrolysis Reactor

|

16mm

|

16mm

|

16mm

|

||

|

Rotate speed of pyrolysis Reactor

|

0.4turn/minute

|

0.4turn/minute

|

0.4turn/minute

|

||

|

Total power

|

15KW

|

15KW

|

15KW

|

||

|

Mode of cooling

|

Water cooling

|

Water cooling

|

Water cooling

|

||

|

Cooling area of condenser

|

100sqm

|

100sqm

|

100sqm

|

||

|

Kind of transmission

|

Internal gear drive

|

Internal gear drive

|

Internal gear drive

|

||

|

Noise dB(A)

|

≤85

|

≤85

|

≤85

|

||

|

Size of Reactor(D×L)

|

2200×6000

|

2600×6600

|

2800×6600

|

||

|

Working form

|

Intermittent operation

|

Intermittent operation

|

Intermittent operation

|

||

|

Delivery time

|

20days

|

20days

|

20days

|

||

|

Weight

|

27T

|

32T

|

35T

|

||

Scheme 3: New design continuous type pyrolysis plant

|

Item

|

Continuous Pyrolysis Plant

|

|

|

||

|

Model

|

DY-C-30

|

DY-C-50

|

DY-C-100

|

||

|

Cpacity

|

30T/D

|

50T/D

|

100T/D

|

||

|

Power

|

65Kw

|

80Kw

|

120Kw

|

||

|

Working type

|

Continuous

|

|

|

||

|

Reactor deisgn

|

Mutiple reactors (The quantity and size depends on the raw material condition)

|

|

|

||

|

Rotating

|

Internal rotating

|

|

|

||

|

Cooling system

|

Recycled waster cooling

|

|

|

||

|

Reactor material

|

Q245R/Q345R boiler plate

|

|

|

||

|

Heating method

|

Indireact hot air heating

|

|

|

||

|

Heating fuel

|

Fuel oil/gas

|

|

|

||

|

Feedstock

|

Waste tire/plastic/rubber

|

|

|

||

|

Output

|

Fuel oil, carbon black

|

|

|

||

Raw Materials & Oil Yields

Waste oil processing process

Project Case

Customer Feedback

Our services

Hot Searches