- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Taidacent

-

Theory:

-

Capacitance Sensor, Capacitance Sensor

-

Output:

-

NPN / PNP / High low level output

-

Description:

-

Non Contact Liquid Level Sensor Switch

-

Sensor type:

-

water level switch

-

ID:

-

XKC-Y26

Quick Details

-

Usage:

-

level measurement, Level Sensor

-

Model Number:

-

Non Contact Liquid Level Sensor Switch

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Taidacent

-

Theory:

-

Capacitance Sensor, Capacitance Sensor

-

Output:

-

NPN / PNP / High low level output

-

Description:

-

Non Contact Liquid Level Sensor Switch

-

Sensor type:

-

water level switch

-

ID:

-

XKC-Y26

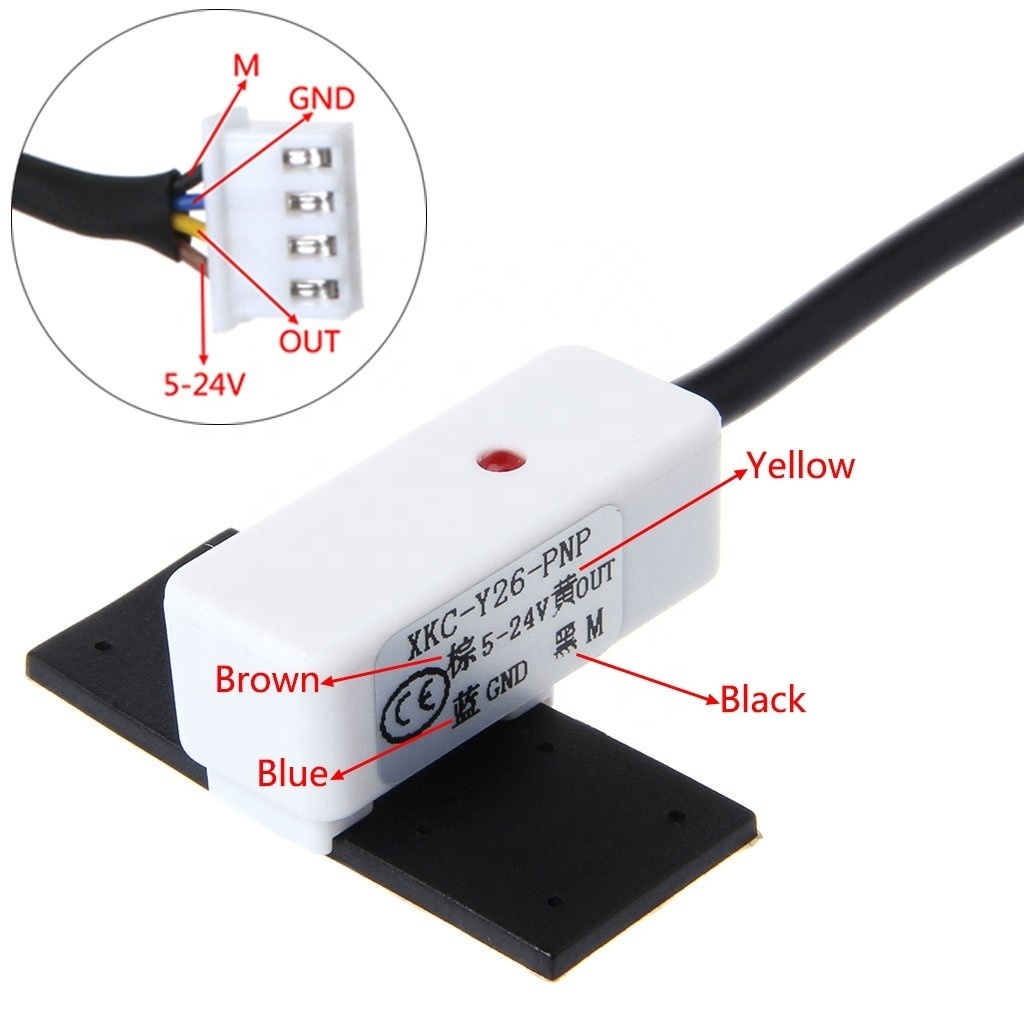

Taidacent XKC-Y26 Non Contact Capacitive Water Level Sensor Contactless Pipe Water Level Detection Liquid Level Sensor Switch

Product Description

The intelligent non-contact liquid level sensor (hereinafter referred to as the liquid level sensor) uses advanced signal processing technology and high-speed signal processing chips, which breaks through the influence of the container wall thickness and realizes a true non-contact to the height of the liquid level in the closed container. Contact detection. The liquid level sensor (probe) is installed above and below the outer wall of the container to be measured (high and low levels of the liquid level). The non-metallic container does not need to be perforated, easy to install, and does not affect production. It can realize the detection of the liquid level of various toxic substances, strong acids, strong bases and various liquids in high-pressure closed containers. The liquid level sensor has no special requirements for the liquid medium and the material of the container, and can be widely used.

Type

XCK-Y26-xxx series products are specially developed for non-metallic pipeline liquid level detection. This series of liquid level sensors are divided into three signal output interfaces, namely high and low level output interface, NPN output interface, PNP output interface; three models The output modes correspond to the following three models:

|

High and low level output interface

|

XKC-Y26-V(5-24V)

|

|

NPN output interface

|

XKC-Y26-NPN 5-12V /24V can be optional

|

|

PNP output interface

|

XKC-Y26-PNP 5-12V /24V can be optional

|

Please leave us a note which one do you want, otherwise we default sent at random.

Features

1. XCK-Y26-xxx series sensors are suitable for the outer wall of non-metallic pipes without direct contact with liquids, will not be corroded by corrosive liquids such as strong acids and alkalis, and will not be affected by scale or other debris.

2. Intelligent liquid level reference adjustment and liquid level memory function, liquid level status display mode, can realize multi-point series connection; can support high and low level output, NPN, PNP signal output (you can explain with the manufacturer when selecting)

3. The detection is accurate and stable, and the boiling water level can be detected.

4. Pure electronic circuit structure, non-mechanical working mode, stable performance and durable life.

5. High stability, high sensitivity, strong interference ability, free from external electromagnetic interference, special treatment for power frequency interference and common mode interference, compatible with all 5~24V power adapters on the market.

6. Strong compatibility, penetrating various non-metallic container pipes, such as plastic, glass, ceramic and other containers, the thickness of the sensing pipe wall can reach 20mm; suitable for various curved, curved, cylindrical containers or pipes Level detection.

7. Wide voltage range (5~24V), suitable for connecting various circuits and product applications.

Working principle

The intelligent non-contact liquid level sensor uses the sensing capacitance of water to detect the presence of liquid. When there is no liquid close to the sensor, the sensor has a certain static capacitance to the ground due to the distributed capacitance. When the liquid level slowly rises close to the sensor, the parasitic capacitance of the liquid will be coupled to this static capacitance, so that the final capacitance value of the sensor becomes larger. The changed capacitance signal is then input to the control IC for signal conversion, which will change The capacitance is converted into a certain amount of electrical signal change, and then a certain algorithm is used to detect and judge the degree of this change. When this change exceeds a certain threshold, it is considered that the liquid level reaches the sensing point.

Product Paramenters

|

Response time

|

500mS

|

|

|

|

Working temperature

|

-20~85℃

|

|

|

|

Sensor sensitivity

|

Outer diameter of pipe D(mm)

|

Sense container wall or tube wall thickness L(mm)

|

|

|

|

D≥100

|

20 ± 2

|

|

|

|

100>D≥80

|

15 ± 2

|

|

|

|

80>D≥60

|

12 ± 1.5

|

|

|

|

60>D≥40

|

7 ± 1.0

|

|

|

|

40>D≥30

|

5 ± 1.0

|

|

|

|

30>D≥20

|

3 ± 1.0

|

|

|

|

20>D≥10

|

1.5 ± 0.5

|

|

|

Applicable pipe diameter range

|

≥10mm

|

|

|

|

Liquid level accuracy

|

±1.5mm

|

|

|

|

Humidity

|

5%~100%

|

|

|

|

Material

|

PC V0 Fireproof material

|

|

|

|

Waterproof performance

|

IP65

|

|

|

Installation Instructions

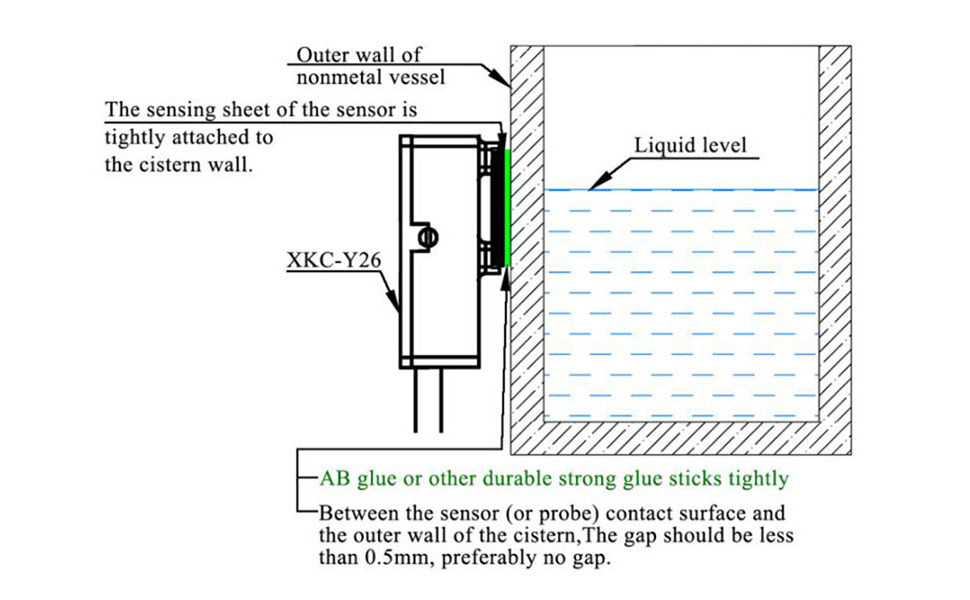

Clearance requirements

Requirements for the clearance between the contact surface of the sensor (or probe) and the outer wall of the container The contact surface of the sensor (or probe) and the outer wall of the container should be tightly pasted with AB or other solid-resistant glue. If there are special requirements, the gap should be less than 0.5mm, preferably no gap, otherwise it may affect the measurement accuracy .

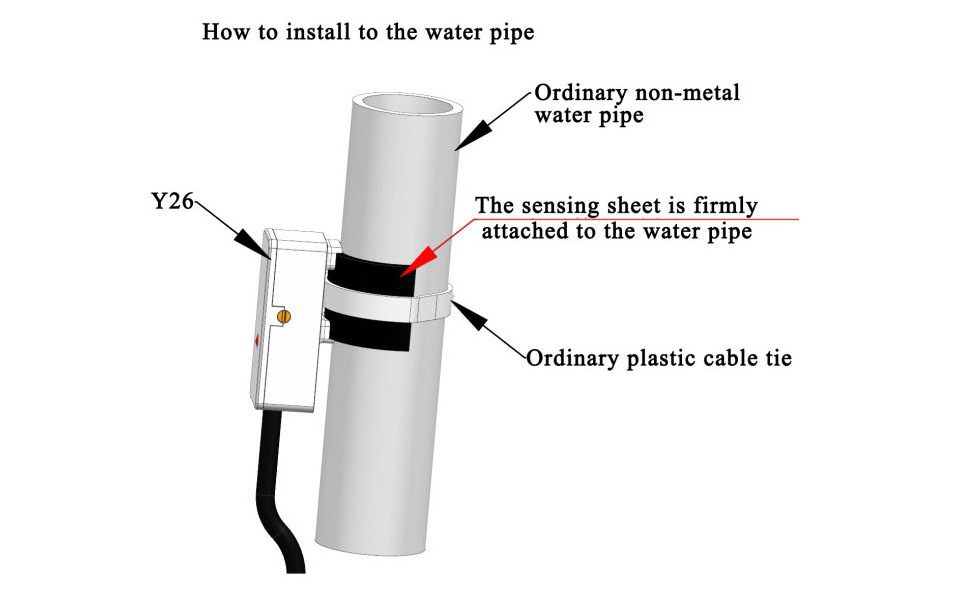

Install to the non-metal water pipe type

The height of the sensed liquid level is related to the sensitivity of the sensor. The higher the sensitivity, the lower the sensed liquid level

Note: The liquid level is sensed in the upper and lower edges of the sensor, which is normal.

The induction sheet can be tightly attached to the pipe with strong glue, or it can be tightened with the pipe with a nylon cable tie. Try to avoid metal and other parts where the probe is installed, so as not to affect the detection. Pipes made of non-metallic materials with a smooth surface, uniform thickness, tight material, and good insulation performance; such as glass pipes, plastic pipes, PC/PVC/PPR pipes, non-absorbent ceramic pipes, acrylic pipes, rubber pipes, etc. or their composites Pipes made of materials.

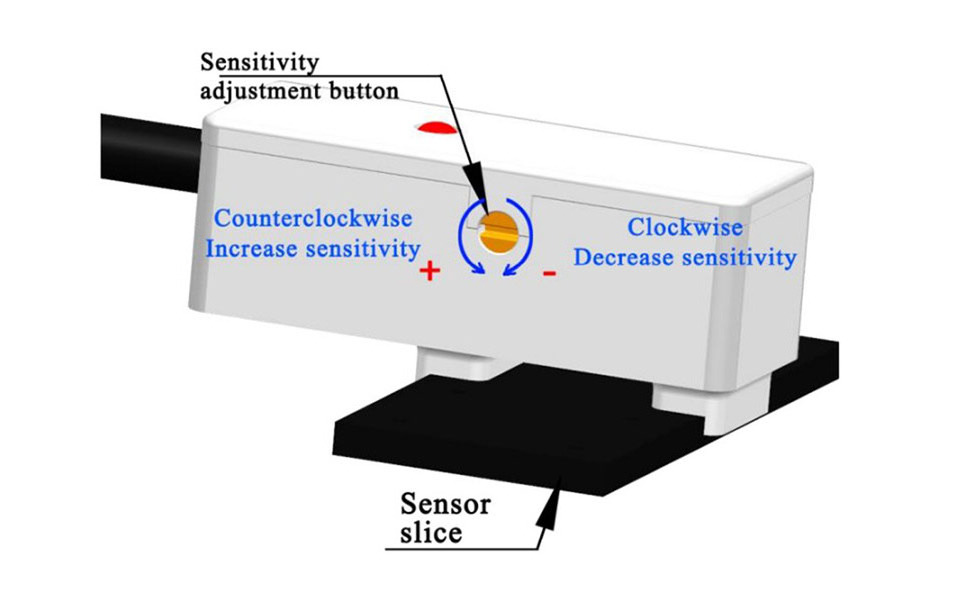

Sensitivity adjustment

If the non-contact liquid level sensor cannot detect or the detected liquid level is too high from the Y26 sensor. The sensitivity knob can be adjusted with a small screwdriver, and there are two setting methods:

1. Low sensitivity adjustment: turn counterclockwise to increase sensitivity.

2. High sensitivity adjustment: turn clockwise to lower the sensitivity.

Details Images

Recommend Products

Hot Searches