- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

depend on the model

-

Weight:

-

3000 KG

-

Color:

-

Required

-

Material:

-

ore like gold, iron

-

manufacturer:

-

Shanghai Clirik Machinery

-

Application:

-

mining, chemical, ceramics

-

Product name:

-

Mineral processing machine

-

Quality:

-

High Reputation

-

Advantage:

-

High Capacity

-

Keyword 1:

-

Energy saving

-

Keywords 2:

-

Environmental protection

-

price:

-

Negotiate a reasonable

Quick Details

-

Production Capacity:

-

3-8 kw

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

Clirik

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

depend on the model

-

Weight:

-

3000 KG

-

Color:

-

Required

-

Material:

-

ore like gold, iron

-

manufacturer:

-

Shanghai Clirik Machinery

-

Application:

-

mining, chemical, ceramics

-

Product name:

-

Mineral processing machine

-

Quality:

-

High Reputation

-

Advantage:

-

High Capacity

-

Keyword 1:

-

Energy saving

-

Keywords 2:

-

Environmental protection

-

price:

-

Negotiate a reasonable

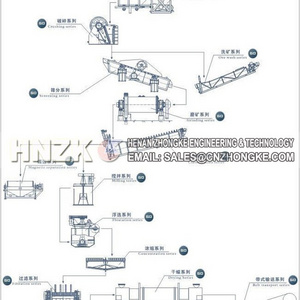

Application of Shanghai Wet type magnetic separator with best price

The high-strength magnetic separator has ultra-high magnetic field strength, which is suitable for removing iron impurities in powder products of ceramics, mining, chemical, electronics and other industries, as well as separation and removal of micro-iron powder and magnetic substances.

The main function of the high-strength magnetic magnetic separator: remove impurities and improve the grade. The equipment is used for the separation and removal of weak magnetic ferrous ore or slag such as lean manganese ore, poor brown iron ore, lean hematite, etc., to separate the concentrate and miscellaneous ore in the ore, thereby improving the metal grade of the concentrate. Also used for impurity removal treatment of feldspar mine, ceramics, quartz sand, etc.

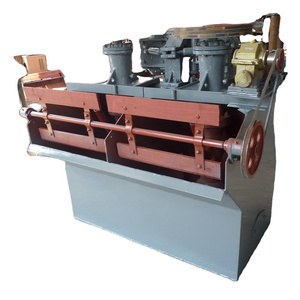

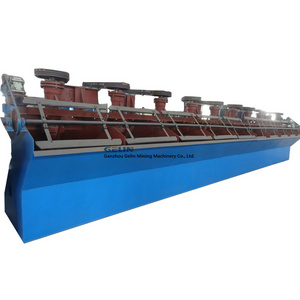

Shanghai Wet type magnetic separator with best price

The wet type permanentmagnetic cylindrical separator is a common magnetic separator that can be widely used in iron ore se parat i on. It is suitable for separating strong magnetic minerals. The magnetic system of magnetic separator is a compound of fine ferrite material and rare earth magnets and the average magnetic induction intensity of the surface of the cylinder is 100~600mT.Magnetic separator is one of aircraft which is the most widely used and high versatility in industries.

Features of Shanghai Wet type magnetic separator with best price

1. Can be operated under either dry or wet working

2. The magnetic field strength is generally between 10,000 and 16,000 GS.

3. One-year maintenance after installation.

Working Principle of Shanghai Wet type magnetic separator with best price

The wet type permanentmagnetic cylindrical separator is mainly composed of cylinder, magnetic system, trough and transmission part. After the ore slurry running into the trough through ore box and effected by the feeding ore water pipe, the ore particles can enter into the ore feeding area in trough. The magnetic ore particles can form ‘magnet group’ or ‘magnet chain’ by magnetic field’s affect. All the ‘magnet group’ or ‘magnet chain’ moves to magnetic poles because of magnetic force in the ore slurry and then they can be attached to the cylinder. Since the polarity of magnetic poles are arrayed alternately and fixed tightly when working, when ‘magnet group’ or ‘magnet chain’ turning with the cylinder, the non magnetic materials, such as matrix which are mixed with ‘magnet group’ or ‘magnet chain’ will drop down during the rolling process. Eventually, the ‘magnet group’ or ‘magnet chain’ attached to the cylinder surface are fine ore. When the fine ore turn to the weakest place of magnetic system in the cylinder, it will be pushed to the fine ore trough by the water coming from unloadore pipe. Non magnetic or weak magnetic ore are left in the ore slurry and then discharged out of the trough, these ore are the gangue. Some magnetic ore can be recycled by putting the gangue in magnetic separator again and then the recycle rate can be increased much. The fine ore can pass through the magnetic separator again and the matrix which mixing with the fine ore can be wiped out to upgrade the purity of fine ore.

Technical Data of Shanghai Wet type magnetic separator with best price

| Iron, gold ore magnetic separator | ||||||

| model | Suitable size (mm) | |||||

| magnetic drum type (mm) | Magnetic induction intensity (gs) | capacity(t/h) | slurry concentration(%) | Power (kw) | ||

| 38 series | 380*1500 | 10000-15000 | 2-30 | 0-3 | 25-45 | 3-8 |

| 50 series | 500*1500 | 10000-15000 | 2-30 | 0-3 | 25-45 | 3-8 |

| 60 series | 600*1500 | 10000-15000 | 5-40 | 0-3 | 25-45 | 3-8 |

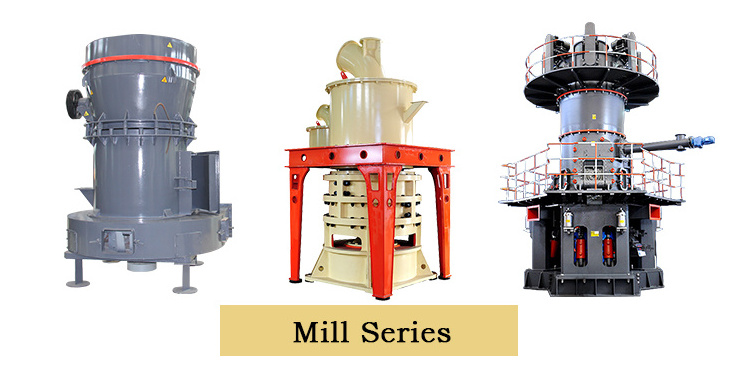

Our company

Shanghai Clirik Machinery Co., Ltd. Is located in Pudong New District of Shanghai, China. As a pioneer enterprise, our company is specialized in research, manufacture and sales of all kinds of mining equipment.

We are the manufacturer of roller mill, stone crusher, mineral separator and etc. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, and owned a professional team, for R&D, production, sales and service.

Customer Visiting

|

|

Services For You:

1.

one year guarantee for whole machine except for wear parts;

2.24 hours technical support by email;

3.

calling service;

4.

user manual available;

5.

reminding for the service life of the wearing parts;

6.

installation guide for clients from both China and abroad;

7.

maintance and replacement service;

8.

whole process trainling and guidance from our technicians.

High quality of after-sales service symbolizes our brand and ability.

We pursue not only good quality products, but also best after sales service.

Your satisfaction is our final purpose.

| Micro Powder Grinding Mill | Untrafine Vatical Roller Mill | High Pressure Suspension Grinding Mill |

|

Finished Size: 300-2500(mesh)Capacity: 0.5-45(t/h) Pass rate: D97 5 micron |

Finished Size: 600-4500(mesh)Capacity: 3-20(t/h) Pass rate: D50 2 micron |

Finished Size: 50-450(mesh)Capacity: 1-28(t/h) Pass rate: D90 30 micron |

Q: Are you a middle man or manufacturer?

A: Our Shanghai Clirik Machinery is a professional mining equipment manufacturer.

Q: How to get in touch with you?

A: You can leave your inquiry below this product, or you can call us 86-021-2023617.

Q: Where is your company?

A: We are in PuDong new area, HeQing twon, FuQing road, No. 19, Shanghai, China.

Shanghai Clirik Machinery

Waiting for Your Inquiry!

Other machine information on our website:

www.carbonblack-process.com

www.calcitegrindingmill.com

www.talcgrindingmill.com