- Product Details

- {{item.text}}

Quick Details

-

Surface Finish:

-

Bright

-

Material:

-

Stainless Steel

-

Color( Stainless Steel wire and rod ):

-

Silver

-

Certificate:

-

ISO9001:2008

-

Length:

-

according to customers' requirements

-

Sample:

-

Free sample

-

Product name:

-

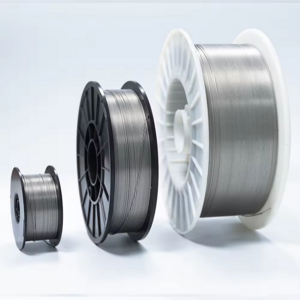

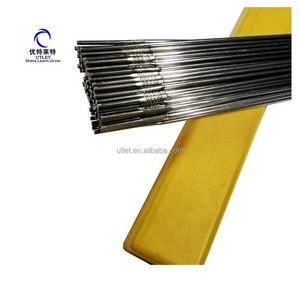

Stainless Steel Welding wire and rod

Quick Details

-

Grade:

-

300 Series

-

Steel Grade:

-

304, 304L, 316, 316L

-

Place of Origin:

-

Hebei, China

-

Surface Finish:

-

Bright

-

Material:

-

Stainless Steel

-

Color( Stainless Steel wire and rod ):

-

Silver

-

Certificate:

-

ISO9001:2008

-

Length:

-

according to customers' requirements

-

Sample:

-

Free sample

-

Product name:

-

Stainless Steel Welding wire and rod

Product Description

Stainless steel welding wire parameter

| Brand | Model | Mechanical properties of Deposited Metal | Wire Diameter | Applications | |

| Tensile Strength Mpa | Specific Elongation(%) | ||||

| ER307Si | GBH09Cr21Ni9Mn4Mo AWS ER307Si | 590~610 | 30~40 | 1.0 1.2 1.6 2.0 2.4 3.2 4.0 | Be used to weld bulletproof steel,stainless steel and carbon steel cladding welding different materials. |

| ER308 | GBH08Cr21Ni10Si AWS ER308 | 570~610 | 36~42 | 1.0 1.2 1.6 2.0 2.4 3.2 4.0 | Be used to weld 18% Cr,8% Ni steels, better heat-resistance crack-resistance |

| ER308L | GBH03Cr21Ni10Si AWS ER308L | 520~560 | 38~44 | 1.0 1.2 1.6 2.0 2.4 3.2 4.0 | Be used to weld low-carbon 18% Cr,8% Ni steels,better crack-resistance corrosion-resistance |

| ER308LSi | GBH03Cr21Ni10Si1 AWS ER308LSi | 520~570 | 37~43 | 1.0 1.2 1.6 2.0 2.4 3.2 | Deposited metal fluidity better than 308L, on weld the operation too more superior. |

| ER309 | GBH12Cr24Ni13Si AWS ER309 | 560~610 | 32~44 | 1.0 1.2 1.6 2.0 2.4 3.2 | Be used to weld 12% Cr,12%Ni steels, and soft steel and stainless steel, chromlum molyodenum steel,different race welding of metals,heat-resistance,corrosion-resistance bear the eclipse even superior. |

| ER309L | GBH03Cr24Ni13Si AWS ER309L | 530~570 | 33~42 | 1.0 1.2 1.6 2.0 2.4 3.2 | Be used to weld low-carbon 22% Cr,12% Ni steels,and soft steel and stainless steel,chrome molyodenum steel,different race welding of metals,heat-resistance,corrosion-resistant bear the eclipse even superior |

| ER310 | GBH12Cr26Ni2Si AWS ER310 | 560~590 | 32~40 | 1.0 1.2 1.6 2.0 2.4 3.2 | Be used to weld 25%Cr,20%Ni steels,hardening welding of high steel material and different metals |

| ER312 | GBH15Cr30Ni9 AWS ER312 | 670~720 | 22~26 | 1.0 1.2 1.6 2.0 2.4 | Be used to weld 29%Cr9%Ni steels, and different race metals,its crack-resistance more superior. |

We can supply stainless steel welding wire and electrode, includes 308L, 308LSi, 308L-16, 309L, 310, 312, 316L

| Type | %Chemical Composition% | Mechanical properties | ||||||||||||

| KSJIS) | ZPSS | C | Cr | Ni | Mo | Others | Heat Treatment | N/mm2 Yield strength | Tensile strength | % Elongation | Hardness | |||

| HB | HRB | HV | ||||||||||||

| AUSTENITE | 301 | 301 | ≤0.15 | 16.018.0 | 6.008.00 | - | - | S | ≥205 | ≥520 | ≥40 | ≤207 | ≤95 | ≤218 |

| 301L | 301L | ≤0.030 | 16.018.0 | 6.008.00 | - | N≤0.20 | S | ≥215 | ≥550 | ≥45 | ≤187 | ≤90 | ≤200 | |

| 304 | 304 | ≤0.08 | 18.020.0 | 8.0010.50 | - | - | S | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 | |

| 304J1 | 304Cu | 0.020.05 | 16.517.1 | 7.57.9 | - | Cu1.92.2 | S | ≥155 | ≥450 | ≥40 | ≤187 | ≤90 | ≤200 | |

| 304L | 304L | ≤0.030 | 18.020.0 | 9.0013.00 | - | - | S | ≥175 | ≥480 | ≥40 | ≤187 | ≤90 | ≤200 | |

| 304N1 | 304N1 | ≤0.08 | 18.020.0 | 7.0010.50 | - | N0.100.25 | S | ≥275 | ≥550 | ≥35 | ≤217 | ≤95 | ≤220 | |

| 304N2 | 304N2 | ≤0.08 | 18.020.0 | 7.5010.50 | - | Nb≤0.15 | S | ≥345 | ≥690 | ≥35 | ≤248 | ≤100 | ≤260 | |

| 309S | 309S | ≤0.08 | S | ≥175 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 | |||||

| 316 | 316 | ≤0.08 | 16.018.0 | 10.0014.00 | 2.003.00 | s | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 | ||

| 316L | 316L | ≤0.03 | 12.0015.00 | S | ≥175 | ≥480 | ≥40 | ≤187 | ≤90 | ≤200 | ||||

| 321 | 321 | ≤0.08 | 17.019.0 | 9.0013.00 | - | Ti5×C%over | S | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 | |

| FERRITE | 409L | 409L | ≤0.03 | 17.019.0 | - | - | Ti6×C%0.75 | A | ≥175 | ≥360 | ≥25 | ≤162 | ≤80 | ≤175 |

| 410L | 410L | ≤0.03 | 11.013.5 | - | - | - | A | ≥195 | ≥360 | ≥22 | ≤183 | ≤88 | ≤200 | |

| 430LX | 430LX | ≤0.03 | 16.019.0 | - | - | TiorNb0.11.0 | A | ≥175 | ≥360 | ≥22 | ≤183 | ≤88 | ≤200 | |

| 430 | 430 | ≤0.12 | 16.018.0 | A | ≥205 | ≥450 | ≥22 | ≤183 | ≤88 | ≤200 | ||||

| 430Ti | 430Ti | ≤0.03 | 19.021.0 | TIO.20.5 | A | ≥205 | ≥420 | ≥25 | ≤162 | ≤80 | ≤175 | |||

| 430J1L | 30J1L | ≤0.025 | 16.020.0 | - | - | Nb8(C%+N%)0.8Cu0.300.80 | A | ≥205 | ≥390 | ≥22 | ≤192 | ≤90 | ≤200 | |

| 436L | 436L | ≤0.025 | 16.019.0 | - | 0.751.25 | TiNbZr8×(C%+N%)0.8 | A | ≥245 | ≥410 | ≥20 | ≤217 | ≤96 | ≤230 | |

| 444 | 444 | ≤0.025 | 17.020.0 | 1.752.50 | Ti,Nb,Zr8×C%+N%)0.8 | A | ≥245 | ≥410 | ≥20 | ≤217 | ≤96 | ≤230 | ||

| MARTENSITE | 410 | 410 | ≤0.15 | 11.513.5 | - | - | - | A | ≥205 | ≥440 | ≥20 | ≤201 | ≤93 | ≤210 |

| 420J1 | 420J1 | 0.160.25 | 12.014.0 | - | - | - | A | ≥225 | ≥520 | |||||

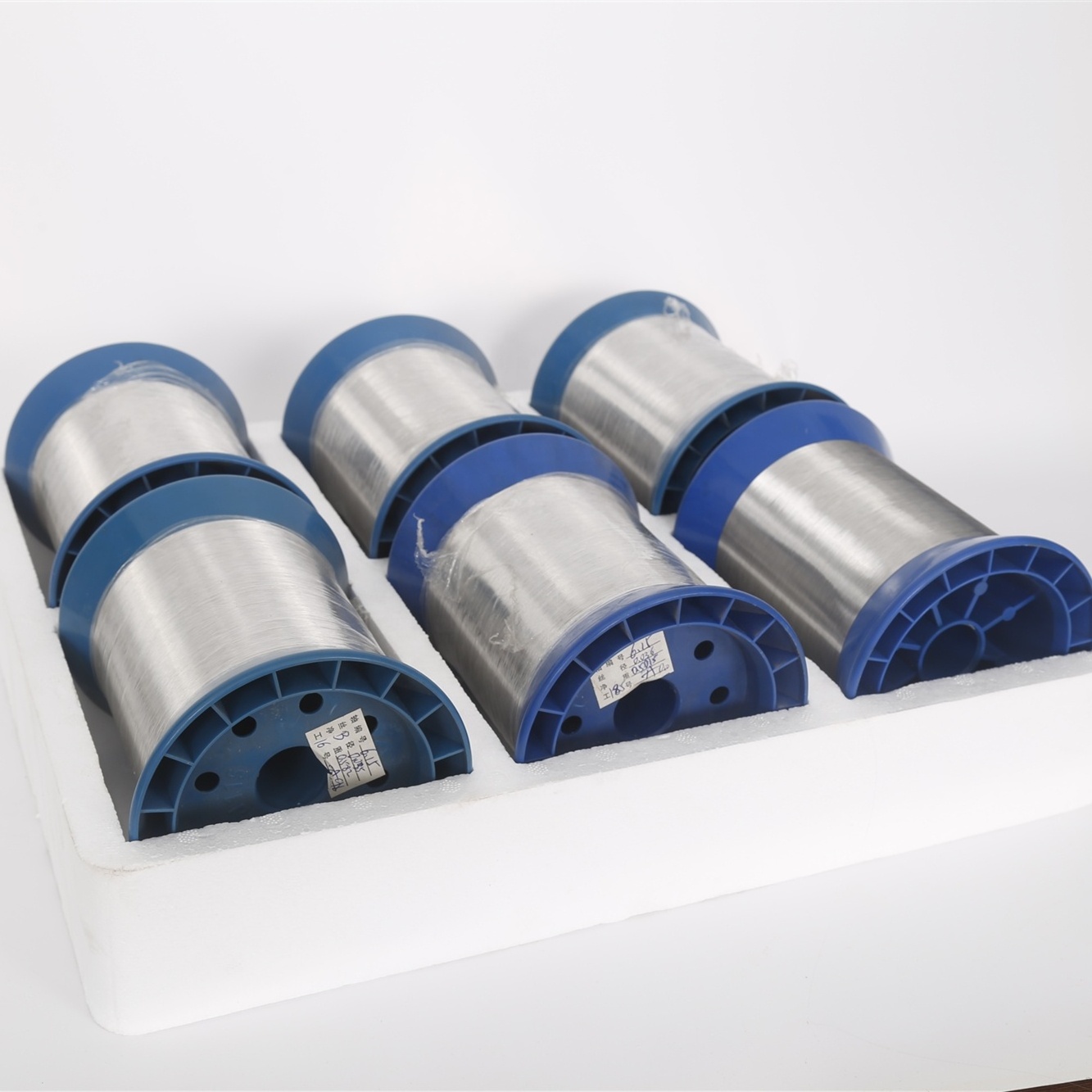

Packaging & Shipping

Package of Stainless Steel Welding wire and rods

Hot Searches