- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TaiXiong

-

Model Number:

-

N35-N52

-

Product Name:

-

Permanent Strong Neodymium Magnet

-

Material:

-

NeFeB Magnet

-

Size:

-

Customized Magnet Size

-

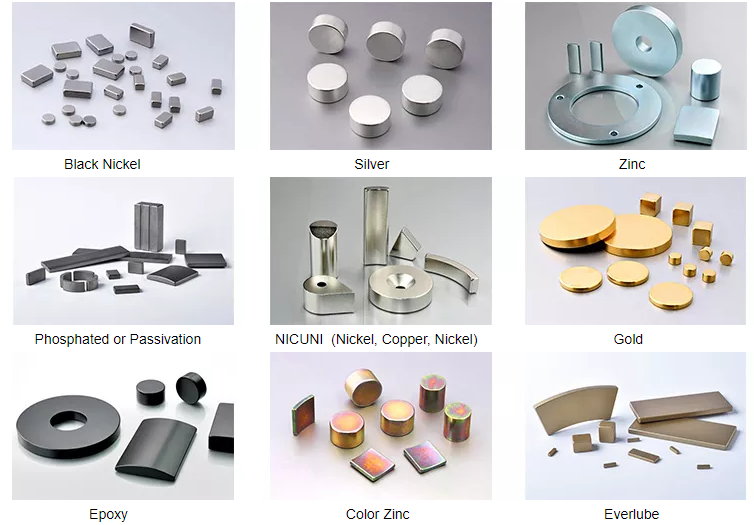

Coating:

-

Ni-Cu--Ni, Zn, Epoxy, Au, Ni-Cu-Ni+Cr

-

Magnetism direction:

-

Customized , Axial, Diameter, and so on

-

Working Temperature:

-

80-220 degree centigrade

-

Magnetic Force:

-

Customized

-

Certification:

-

RoHs,CE ,ISO9001

Quick Details

-

Tolerance:

-

±1%

-

Grade:

-

NdFeB Magnets, NdFeB, N35-N52

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

TaiXiong

-

Model Number:

-

N35-N52

-

Product Name:

-

Permanent Strong Neodymium Magnet

-

Material:

-

NeFeB Magnet

-

Size:

-

Customized Magnet Size

-

Coating:

-

Ni-Cu--Ni, Zn, Epoxy, Au, Ni-Cu-Ni+Cr

-

Magnetism direction:

-

Customized , Axial, Diameter, and so on

-

Working Temperature:

-

80-220 degree centigrade

-

Magnetic Force:

-

Customized

-

Certification:

-

RoHs,CE ,ISO9001

|

Type

|

Permanent Powerful Neodymium Magnets

|

|

|

|

|||

|

Material

|

Sintered Neodymium Magnets

|

|

|

|

|||

|

Coating

|

Ni, Zn, Epoxy, Parylene, Gold, Passivated, etc

|

|

|

|

|||

|

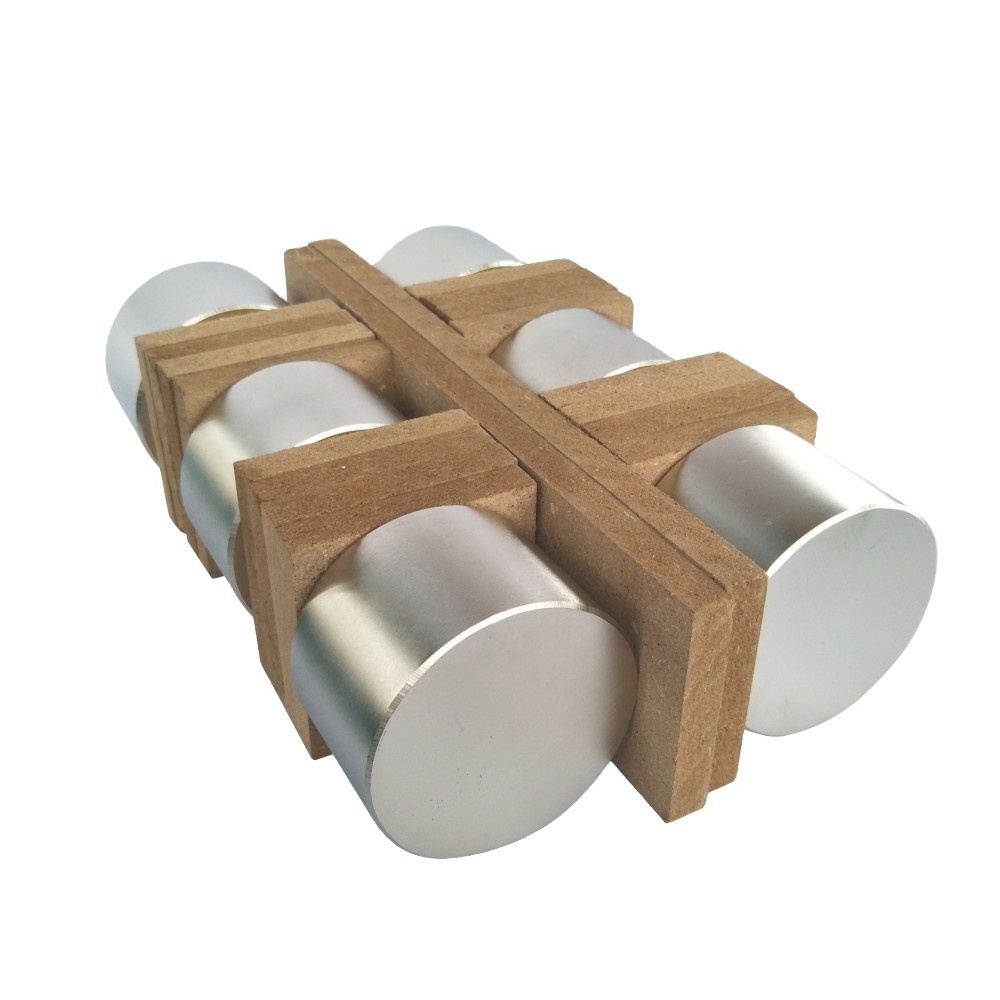

Shape

|

Block, Bar, Cube, Disc, Ring, Cylinder, Ball, Arc, Trapezoid, etc

|

|

|

|

|||

|

Density

|

7.5-7.6 g/cm³

|

|

|

|

|||

|

Delivery date

|

7-10 days for common samples, 20-25 days for mass produciton

|

|

|

|

|||

|

Magnetic Grade

&

Working Temperature

|

Magnetic Grade

|

|

Working Temperature

|

|

|||

|

|

N35-N45

|

|

80 ℃(176

℉)

|

|

|||

|

|

N48-N52

|

|

60 ℃(160 ℉)

|

|

|||

|

|

35M-50M

|

|

100 ℃(212 ℉)

|

|

|||

|

|

33H-48H

|

|

120℃(248 ℉)

|

|

|||

|

|

33SH-45SH

|

|

150 ℃(302 ℉)

|

|

|||

|

|

30UH-40UH

|

|

180 ℃(356 ℉)

|

|

|||

|

|

28EH-38RH

|

|

200℃(392 ℉)

|

|

|||

|

|

28AH-33AH

|

|

220 ℃(428 ℉)

|

|

|||

1> Disc, cylinder and Ring shape magnet can be magnetized Axially or Diametrically.

3> Arc shape magnets can be magnetized Diametrically, through Width or Thickness.

Special direction of magnetization can be customized as required.

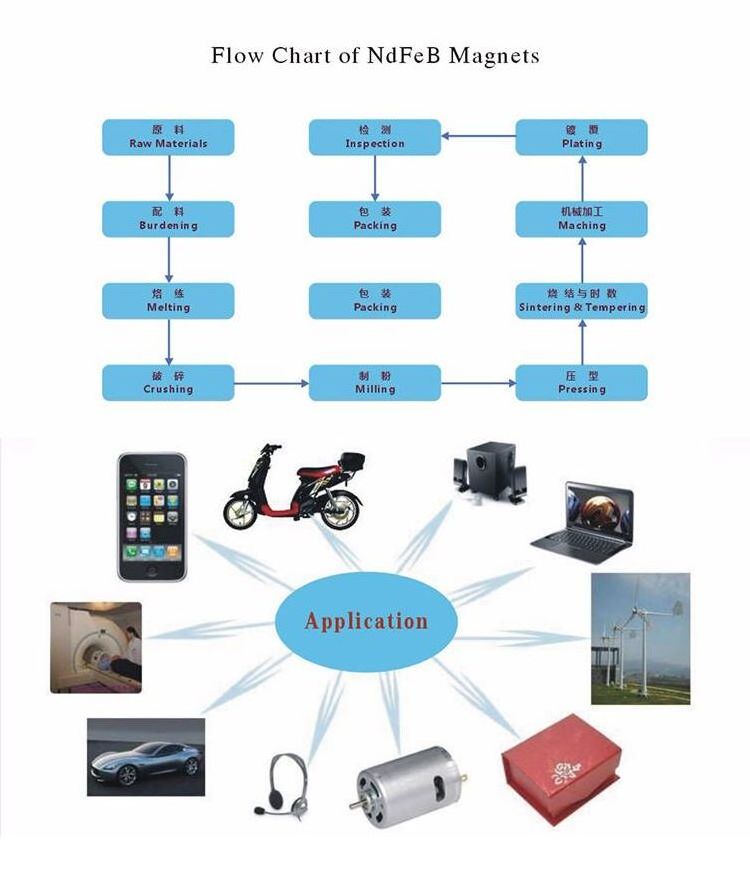

1. FLOW CHART

and are under our strict control.

2. QUALITY CONTROL

3> Magnetic Flux report and Demagnetization Curve can be offered according to request.

3. CORE ADVANTAGE

2> Full Scale Production

Capacity 200 tons, Specialized Factories.

3> The Integrated Industry Supply Chain.

4> Outstanding Product.

N54, N52M, N50H, 46SH, 42UH, 38eh, 33AH etc.

The AH series with 40kOe super-high coercive forcecan replace SmCo magnets in most applications.

The salt spray test and humidity heat test of the highanti-corrosion coating Nickel+Copper+Epoxy is

typically more than 500 hours.

PCT: 130°C, humidity 100%, vapor pressure 2.7 bar,20 days, average low weight loss <2 mg/cm2.

Q1: Could I get samples?

A: Samples are available and free.

Q2: How about your delivery date?

A: 3-7 days for samples and 15-20 days for mass production.

Q3: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q4: What is the usual payment method?

A: T/T, Paypal, L/C, VISA, e-Checking,Western Union.

Q5: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.