- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1*2*0.7m

-

Warranty:

-

15 months

-

Material of recycling machine:

-

304 stainless steel

-

Function:

-

Film Plastic Melter Densifier

-

Keywords:

-

Plastic Melter Densifier

-

Inverter:

-

ABB

-

Motor:

-

Siemens

-

Bearing:

-

NSK

-

Capacity:

-

100-500 Kg/h

-

Final product:

-

PP PE granules

-

Final product moisture:

-

5%

-

PPM:

-

<200

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE ISO

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

wedo

-

Warranty of core components:

-

15 months

-

Dimension(L*W*H):

-

1*2*0.7m

-

Warranty:

-

15 months

-

Material of recycling machine:

-

304 stainless steel

-

Function:

-

Film Plastic Melter Densifier

-

Keywords:

-

Plastic Melter Densifier

-

Inverter:

-

ABB

-

Motor:

-

Siemens

-

Bearing:

-

NSK

-

Capacity:

-

100-500 Kg/h

-

Final product:

-

PP PE granules

-

Final product moisture:

-

5%

-

PPM:

-

<200

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE ISO

-

Marketing Type:

-

Hot Product 2019

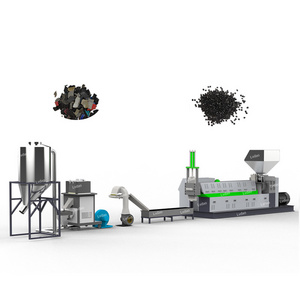

Waste Film Plastic Melter Densifier

Description of Plastic Melter Densifier:

Plastic Densifier agglomerator machine is reduces large volume of plastic to smaller volume or it can also be defined as reduction of plastic volume in a machine called as agglomerator.

Plastic agglomerating machine in plastic granulator mainly used for cutting and recycling thermoplastic films and chemical fibers, such as PP/PE/LDPE/HDPE and so on. It can make plastic films and materials with less than 2mm wall thickness materials into granules. It is an ideal equipment for thermoplastic films and chemical fibers recycling and granulating.

Photos of Waste Film Plastic Melter Densifier :

Usage of Waste Film Plastic Melter Densifier :

It can make granule for soft PVC, high-low-pressure polyethylene, polystyrene, thermoplastic polypropylene plastics and other waste products, or the films, also be of granulation for the abandoned polystyrene foam products.

The main shaft is metal processed after being heat-treated and adjusted straight and this machine is of low noise but high output, with the removable blade as the fixed blade, resulting in convenient repair and maintenance.

Specifications of Waste Film Plastic Melter Densifier :

|

Main Technical Parameter of Plastic Melter Densifier |

||||

|

ZL200 |

ZL300 |

ZL500 |

ZL800 |

|

|

Volume(L) |

200 |

300 |

500 |

800 |

|

Motor power(KW) |

55 |

75 |

90 |

110 |

|

Number of fixed blade(PCS) |

6 |

6 |

6 |

8 |

|

Number of rotary blade(PCS) |

2 |

2 |

2 |

2 |

|

Main axes rotary speed(RPM) |

850 |

820 |

750 |

650 |

|

Capacity(KG/H) |

200 |

300 |

450 |

600 |

|

Heating mode |

Friction heating |

|||

|

Grinder, Granulator, Plastic crushing machines |

Single shaft, Double shaft P lastic shredding machines |

|

Waste PET bottles Plastic Recycling Machinery |

Waste PP PE film bag bottles Plastic Recycling Machinery |

|

PET Plastic pellet making machine, plastic pelletizer machine |

PP PE Plastic pellet making machine, plastic pelletizer machine |

Wedo have a fully step for the Waste Film Plastic Melter Densifier producing before packing and shipping, this ensure the plastic recycling machine will delivery in good quality, and custerm will get good machine.

We do fully best service for you in Waste Film Plastic Melter Densifier