Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Qingdao city,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

380V/3P/50HZ(Customized)

-

Dimension(L*W*H):

-

20m*5.5m*3.5m

-

Power (kW):

-

185

-

Weight:

-

2700 KG

-

Raw material:

-

PP PE ABS PC PMMA Granules

-

Keywords:

-

Sheet/Board Line

-

Final product:

-

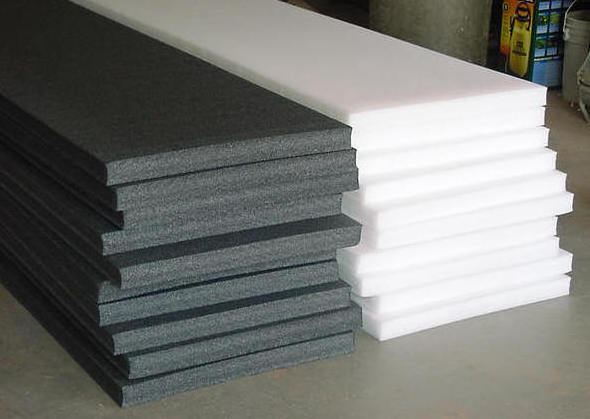

plastic thick board/sheet

-

Name:

-

Pp Sheet Making Machine

-

Product name:

-

PE ABS PMMA PC Plastic Sheet Extruder Machine

-

sheet thickness:

-

1.5mm-10mm

-

sheet width:

-

1220m-2150mm

-

Usage:

-

Plastic sheet Forming Machine

-

After Warranty Service:

-

After-sales Service Provided

-

Screw type:

-

Single Srew

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Qingdao city,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

380V/3P/50HZ(Customized)

-

Dimension(L*W*H):

-

20m*5.5m*3.5m

-

Power (kW):

-

185

-

Weight:

-

2700 KG

-

Raw material:

-

PP PE ABS PC PMMA Granules

-

Keywords:

-

Sheet/Board Line

-

Final product:

-

plastic thick board/sheet

-

Name:

-

Pp Sheet Making Machine

-

Product name:

-

PE ABS PMMA PC Plastic Sheet Extruder Machine

-

sheet thickness:

-

1.5mm-10mm

-

sheet width:

-

1220m-2150mm

-

Usage:

-

Plastic sheet Forming Machine

-

After Warranty Service:

-

After-sales Service Provided

-

Screw type:

-

Single Srew

Product Description

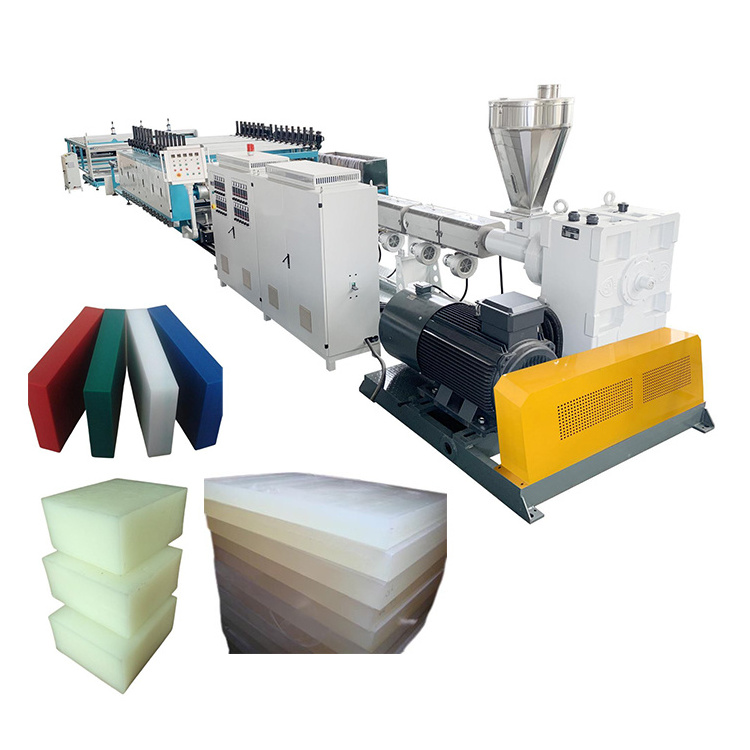

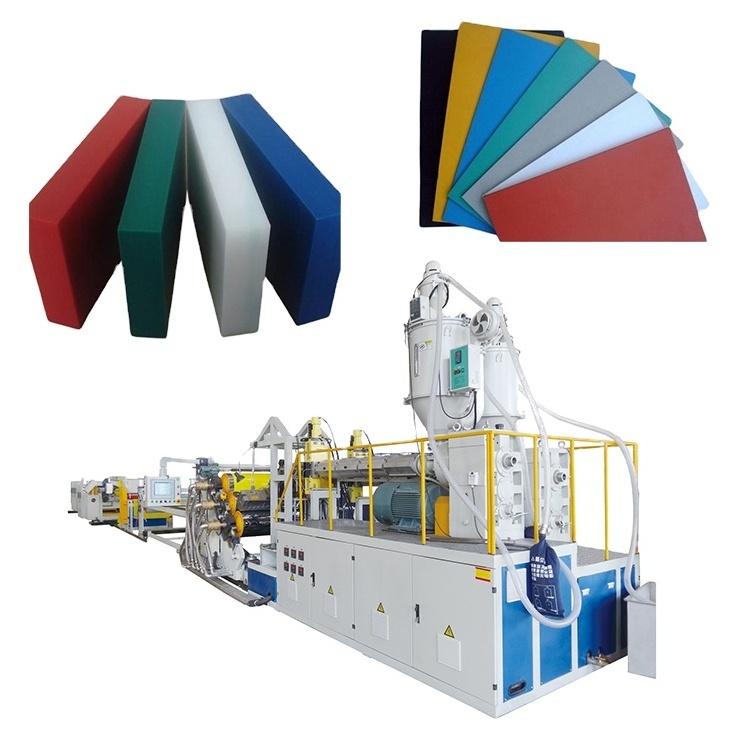

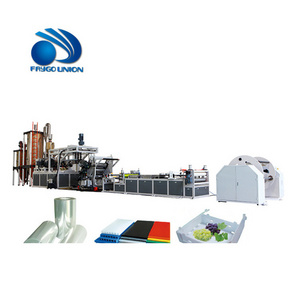

PE/PP/ABS thinck board/ sheet extrusion machine line

Mainly used for the production of PP / PE / ABS

single layer or multi-layer sheet or plate

and ,other transparent and opaque soft and hard boards.And which can product the thick board ,thickness of the board can be done from 20 to 60mm, width range from 750 to 1800mm Production equipment has compact structure, superior performance, high degree of automation, flat and stable operation, uniform plasticizing, stable extrusion capacity, high output, long life and other characteristics.

Application

Products have the advantages of impact resistance, corrosion resistance, high heat resistance, non-toxic and tasteless, smooth and beautiful surface, easy processing, welding will not produce toxic gas.S

uitable in the fields of packaging, stationery, chemicals, construction, household appliances and so on.

W

idely used instruments, instrument parts, lighting, decoration, construction, aircraft, auto parts, medical equipment,technology products, electrical insulation materials, specimens, signs, and a variety of light industry, culture and education,and daily necessities.

Specification

|

Model

|

Suitable Material

|

Max. Width(mm)

|

Thickness Range (mm)

|

Extruder Model

|

Max. Output(Kg/h)

|

|

SZB-1400

|

PE/PP/ABS

|

1400

|

1.5-8

|

SJ120/36

|

400

|

|

SZB-2000

|

PE/PP/ABS

|

2000

|

1.5-8

|

SJ150/36

|

500

|

Detailed images

Products process:

Single screw extruder---Die head---

three-roll setting machine---Cooling stacker---Hall-off machine---cutting machine---stacker

Single screw extruder

Special screw structure, electronics, hard gear face reducers to ensure high effective material extrusion capacity.

High efficiency, high speed extrusion system; The feeding section and the forced cooling device are integrated into one unit, to ensure under high speed and large extrusion, the line runs adeptly and efficiently.

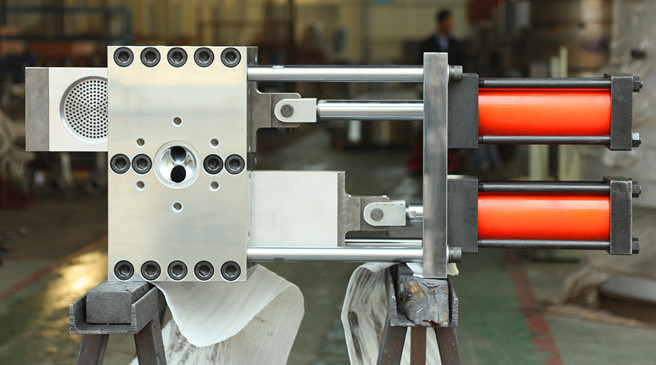

Die head

Suitable compression ratio to ensure uniform flow stability.

New improved die-head technology, ensure eliminate pipes weld marks effectively.

Three-roll setting machine

According to the material properties, adopting vertical three-roller, oblique three-roller, horizontal three-roller calendar.

Internal roller temperature control using a unique flow channel, so that the stability of uniform distribution roller. The

independent oil temperature control for three roller to ensure more stable and exact control.

Internal roller temperature control using a unique flow channel, so that the stability of uniform distribution roller. The

independent oil temperature control for three roller to ensure more stable and exact control.

Cooling stacker

According to product specifications, configurations with different specifications of the stainless steel cooling frame

.

Cutting machine

Hot Searches