- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥99%

-

Voltage:

-

110V 220V 380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Paixie

-

Dimension(L*W*H):

-

1200*900*2200mm

-

Weight:

-

450 KG

-

Machine Name:

-

Small bottle filling capping machine

-

Yield:

-

1000-8000BPH(Customized)

-

Accuracy:

-

≥99%

-

Driving:

-

Servo motor

-

Metal Quality:

-

SS304 and SS316

-

Work voltage:

-

110/220/380V 50/60HZ

-

Power:

-

1-3.5KW

-

package:

-

Wooden case

-

After-sales Service Provided:

-

Online technical support

-

Marketing Type:

-

New Product 2020

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Metal, Glass, Other

-

Filling Material:

-

Beer, Other, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

≥99%

-

Voltage:

-

110V 220V 380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Paixie

-

Dimension(L*W*H):

-

1200*900*2200mm

-

Weight:

-

450 KG

-

Machine Name:

-

Small bottle filling capping machine

-

Yield:

-

1000-8000BPH(Customized)

-

Accuracy:

-

≥99%

-

Driving:

-

Servo motor

-

Metal Quality:

-

SS304 and SS316

-

Work voltage:

-

110/220/380V 50/60HZ

-

Power:

-

1-3.5KW

-

package:

-

Wooden case

-

After-sales Service Provided:

-

Online technical support

-

Marketing Type:

-

New Product 2020

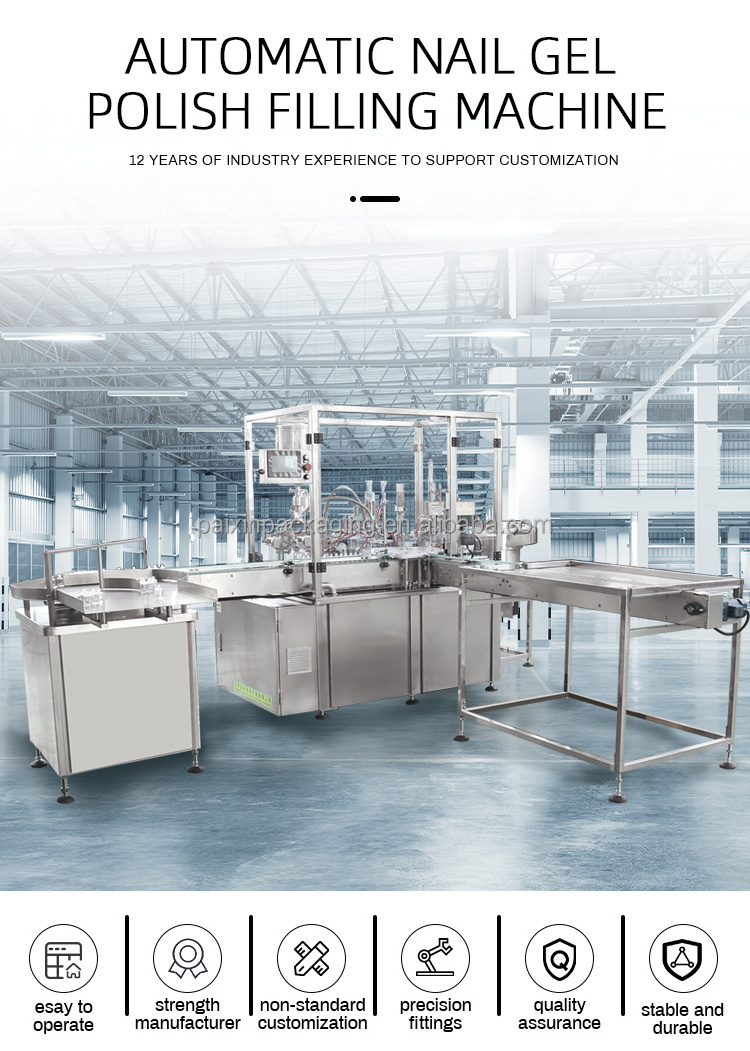

Product Overview

Introduction:

1. Touch screen PLC control, no bottle filling, frequency conversion speed regulation, running speed continuously adjustable.

2. The filling head probes to about 2/3 of the bottle to start filling, filling while rising, to prevent the liquid from

impacting and foaming, no bottle will not be filled, no bottle will not be capped.

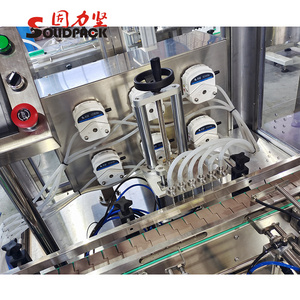

3. The filling system adopts a full quick-connect design, and the part in contact with the material can be completely

disassembled without any tools, which is more convenient for cleaning and maintenance.

4. Intelligent control of filling quantity: The filling quantity can be directly inputted on the touch screen, and the filling

quantity can be automatically calibrated. Switching between different specifications, it is extremely convenient to adjust the loading capacity, and there is no requirement for the level of the operator. Avoid the trouble of traditional debugging and testing.

5. Intelligent manipulator screw cap, better effect, touch screen setting torque, quick and convenient switching between different specifications, and has the alarm function of unqualified screw cap tightness.

6. Overload protection and alarm prompt function, more safe and reliable.

Parameter

|

No

|

Model

|

PX-2

|

|

1

|

Filling nozzle number

|

2

|

|

2

|

Capacity

|

20-40 bottles/min

|

|

3

|

Filling range

|

10-120ml

|

|

4

|

Power

|

1.9 KW

|

|

5

|

Power supply

|

1 Phase 220V

|

Application

Details Images

Filling Volume ,Filling Speed,Capacity Etc All Display,Simple And Convenient Operation

Fast and high-precision filling system, with bottle entry detection, no bottle no filling system. The filling error is only 1%.

Auto Sorting Cap Into Loading Tunnel *Customized On Specific Cap Size *Can Be Adjusted Of The Sorting Speed

Automatic Feeding Andclamping Cap,Servo Lifting,Servo Positioning Andclamping.

The Rotary Dish Can Help To Fix And Transport Bottles During Working.This Dish Should Be Customized According To Bottle Size.Change Different Rotary Dish For Different Kinds Of Bottles.

The Internal Mechanism Of The Chassis Is Orderly And Easy To Maintain,So As To Achieve Safe And Stable Production

We'll change into your standard plug before shipping,such as American plug, UK plug, European plug...

Hot Searches