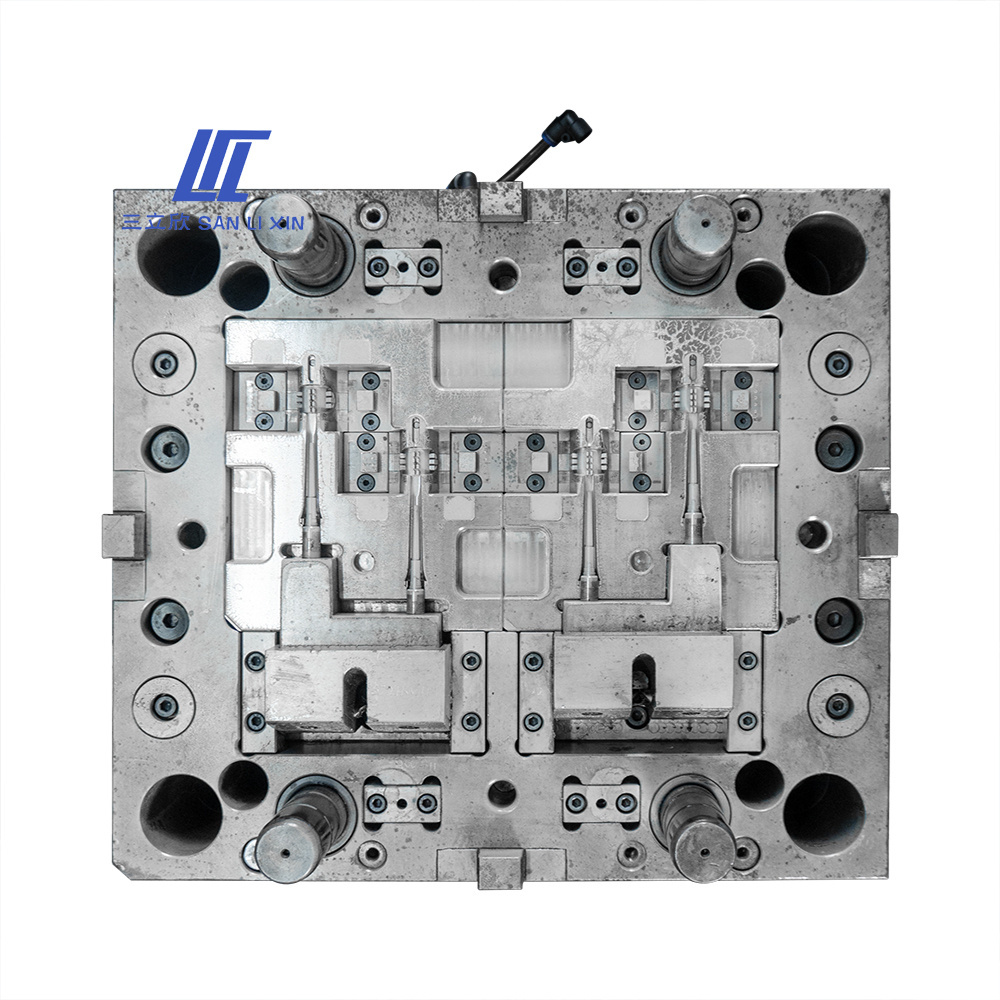

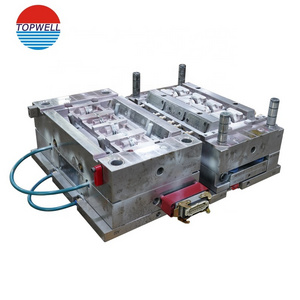

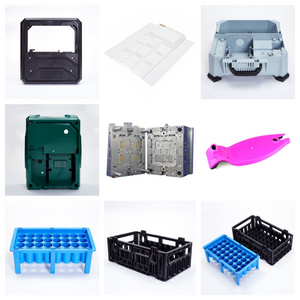

Provide Mold Design, Mold Making, Mold Testing, Injection molded parts, Insert Molding, Over Molding, IML Injection, Double shots Molding, Surface treatment, Products assembly, Packing, Shipping, etc. services.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

S-26

-

Product Name:

-

Plastic Injection Mold

-

Material Experience:

-

ABS/PA66/PC/ASA/TUP/POM/Acetal/Acetron

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Application:

-

Injection Molding Plastic Parts

-

Surface treatment:

-

Polish. Etched. Texture

-

Size:

-

Customized Size

-

Mould Life:

-

300000-500000 Shots

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Runner:

-

Hot Runner\ Cold Runner

-

Drawing Format:

-

3D.STP. STEP . IGS . PRT . X_T

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

slx

-

Model Number:

-

S-26

-

Product Name:

-

Plastic Injection Mold

-

Material Experience:

-

ABS/PA66/PC/ASA/TUP/POM/Acetal/Acetron

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Application:

-

Injection Molding Plastic Parts

-

Surface treatment:

-

Polish. Etched. Texture

-

Size:

-

Customized Size

-

Mould Life:

-

300000-500000 Shots

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Runner:

-

Hot Runner\ Cold Runner

-

Drawing Format:

-

3D.STP. STEP . IGS . PRT . X_T

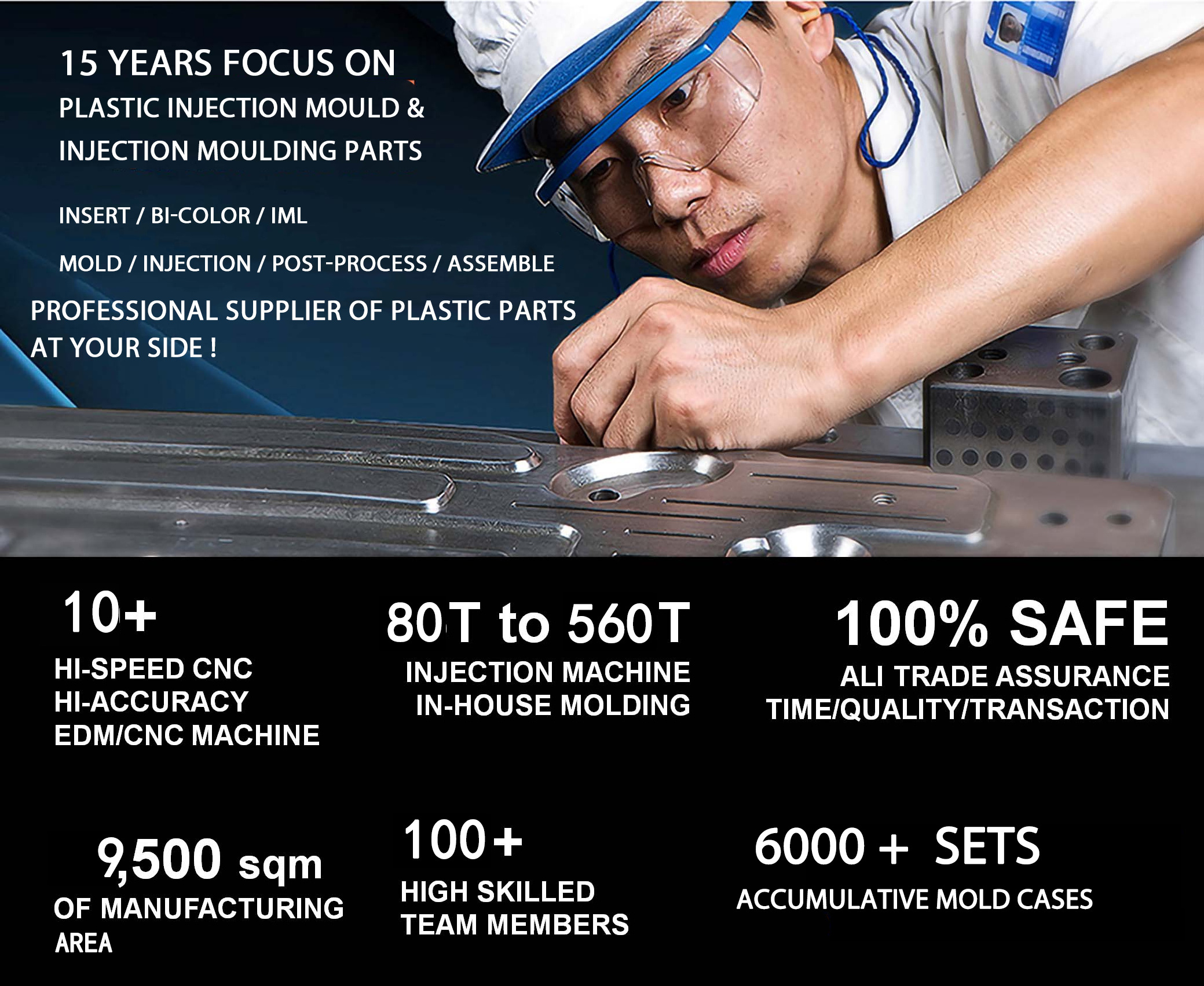

DONGGUAN SANLIXIN PLASTIC TECHNOLOGY CO.,LTD.

Products Description

Plastic Injection Moulds

Injection Mold Experience:

16+ Years

Mould Precision:

+/- 0.01mm

Molding Parts Tolerance:

+/- 0.02mm

Mould Life:

50-500K shots

Maximum Mould Sizes:

1-1.5 M

Mold Building Lead Time:

15-30 Days

Annual Capacity:

500 Sets

Surface Finish:

Polishing/EDM finish/Texture/Sand Blasting/MT/YS/SPI

Mold Steel:

718, 718H, 738, SKD-61, S136, S136H, NAK-80 Heat Treatment

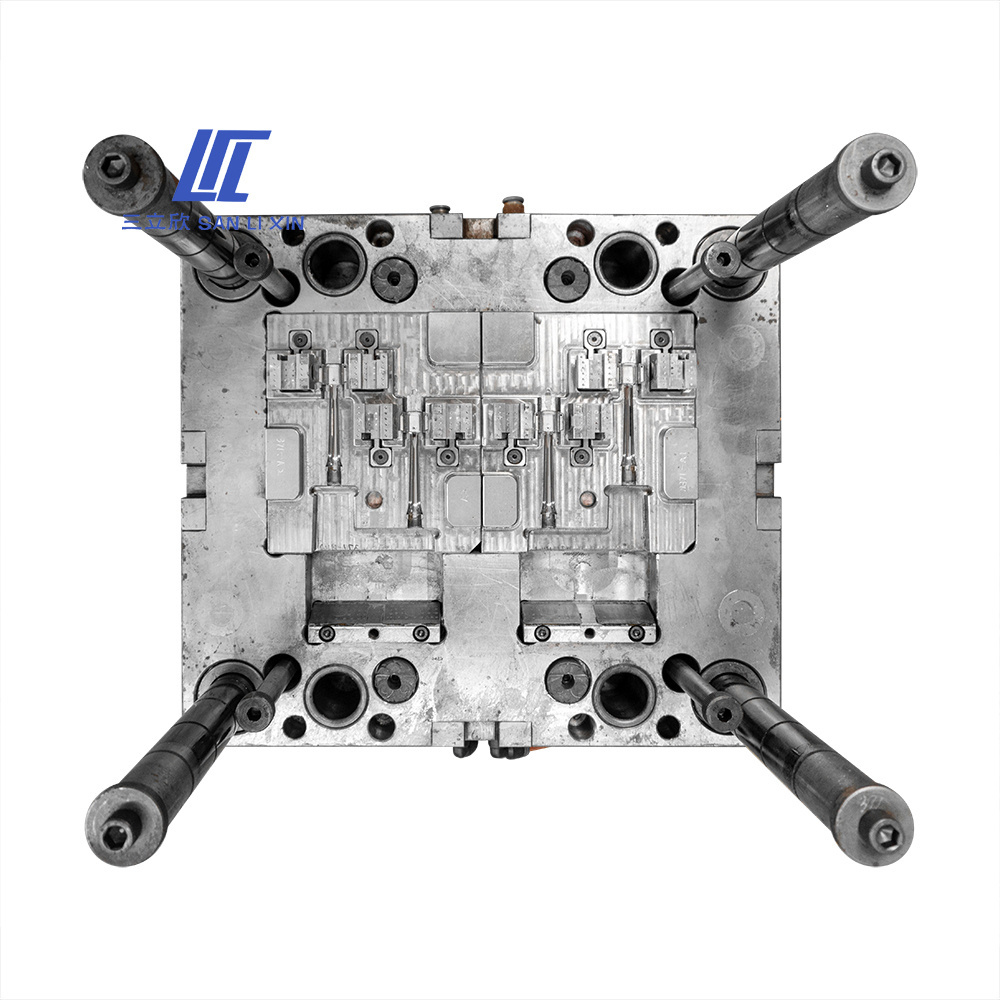

Injection Molding Plastic Parts

Injection Molding Tonnage:

35-650 Ton

One-Station:

Mold/Injection/Painting/Plating/Assembly

Material:

Hard Plastic:

ABS, PC, PPS, POM, PMMA, PA6, PA66, PVC, PET, PP

or Fireproof/Fibered, Soft Plastic: TPU/TPE/TPR

Molding Tolerance:

0.02mm -0.05mm

Surface Finish:

Texture, Sand Blasting, MT/YS, Smooth, Glossy, Spraying, Plating

Parts Types:

IML Injection/Insert Injection/OverMolding/Bi-color Molding

Color:

Black/White/Colourful/Transparent/Semi-transparent

|

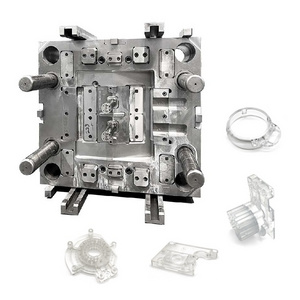

Technique

|

Injection Mould & Injection Molding Plastic Parts: Insert, Bi-color, IML

|

|

Service

|

Mold, Injection, Printing, Painting, Plating, Assembly One-Station

|

|

Mould Materials

|

P20, H13, 718, 718H, NAK80, S136, SKD61,SKD11 etc.18~56 HRC

|

|

Plastic Raw Materials

|

ABS, PP, PC, PS, PPS, PE, PU, PVC, PA6, PA66, TPU, POM, PBT, HIPS, PMMA ect.

|

|

Mold Hot Treatment

|

Quencher, Nitridation, Tempering,etc.

|

|

Mould Base

|

Standard mould base,LKM, HASCO, S50C ect.

|

|

Mould Precision

|

±0.01mm/0.1mm

|

|

Molding Parts Tolerance

|

±0.02mm -0.05mm

|

|

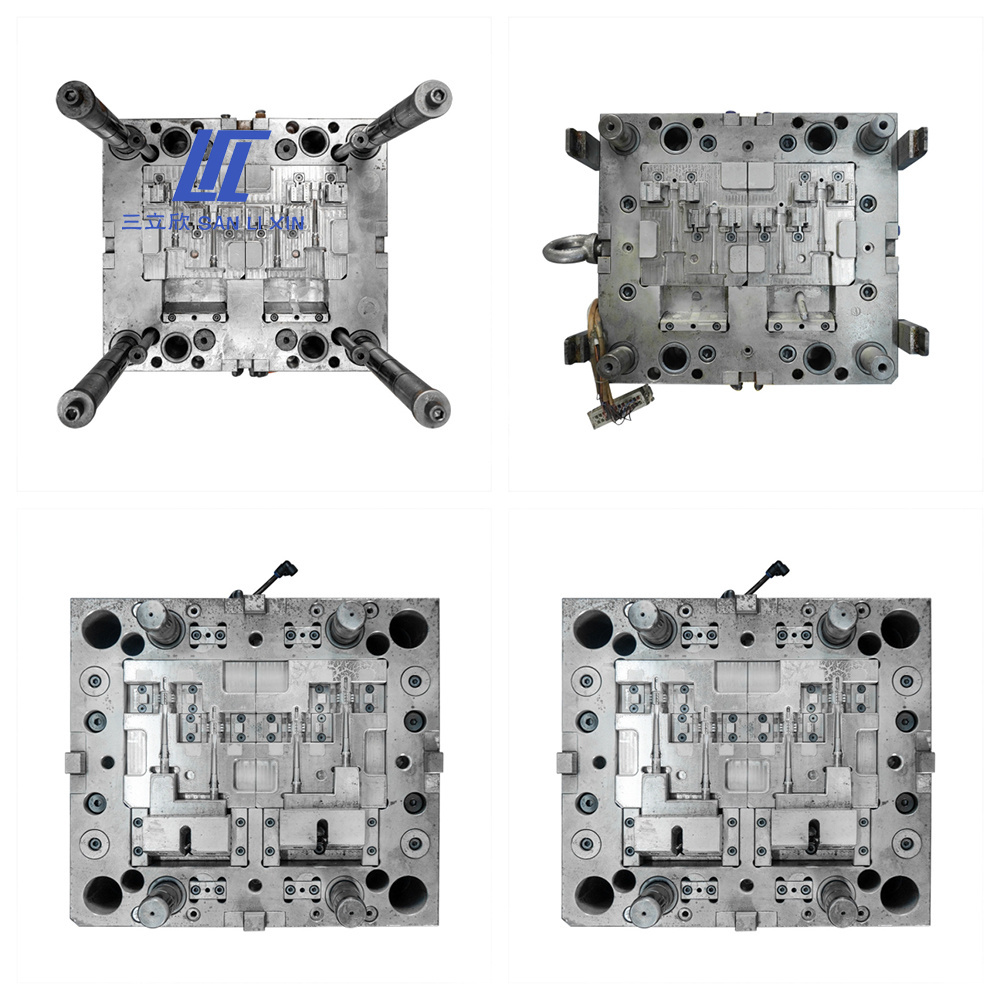

Cavity Number of Mold

|

Single cavity, Multiple cavity or one mold with different products

|

|

Runner System

|

Hot runner, Cold runner with full automaticity(YUDO/HASCO)

|

|

Gate Type

|

Pin point gate, side gate, slim gate, tunnel gate, banana gate

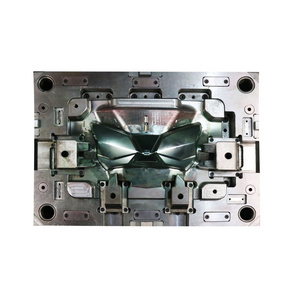

|

|

Sliding Block

|

design according to your parts stucture

|

|

Clamp Forces

|

from 80 Ton to 560 Ton

|

|

Maximum Mould Size

|

2,000*1,500*1,000mm

|

|

Maximum Mould Weight

|

5800g/13 Pound

|

|

Ejection System

|

Motor/hydraulic cylinder/stripping plate/angle pin/ejecting block,etc

|

|

Cooling System

|

water cooling or Beryllium bronze cooling

|

|

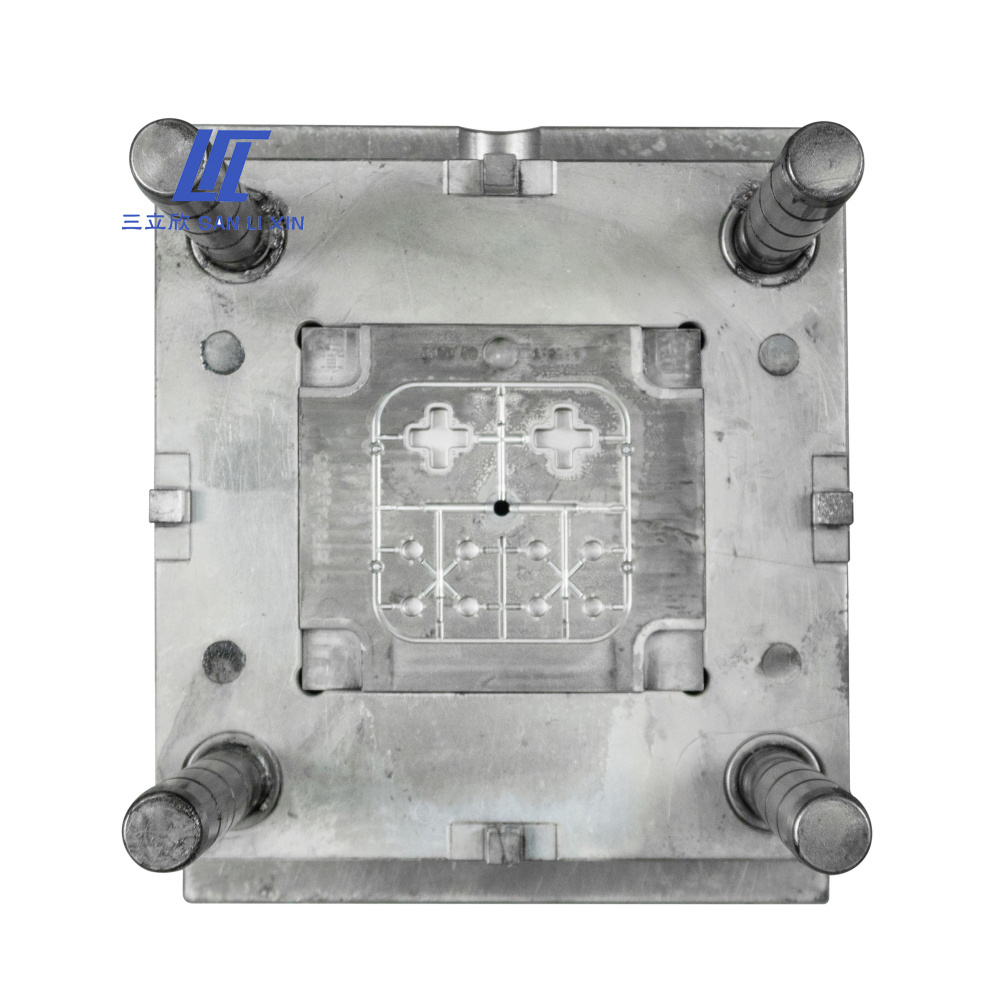

Mould Standard

|

HASCO,DME, MasterFlow standard.or according to custom's request

|

|

Design Software

|

UG, PROE, CAD, CAXA, SOLIDWORK, PRESSCAD, ect.

|

|

Drawing Format

|

we accept DXF,DWG,IGS,STP,SIDPRT,X_T and so on

|

|

Injection Mould Life

|

50,000-5,000,000 times shots

|

|

Surface treatment of Mould

|

Mirror Polishing, Texture/Graining,Sand Blasting,MT/YS/SPI,Words Corrosion

|

|

Surface Treatment of Products

|

Texture, Silk Printing, Spraying/Coating, Frosted surface, Polishing, Plating

|

|

Color

|

Black/White/Colourful/Transparent/Semi-transparent, PANTONE or RAL

|

|

Design Time

|

Within 3 days(Generally)

|

|

Mould Production Cycles

|

15-60days, on basis of the difficulty level

|

|

Plastic Products Production Cycles

|

7-15days

|

|

Parts Application

|

Exterior, Structural, Functional for Household applicance, Vehicle, Medical

|

Technological Process

Hot Searches