- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

3

-

Range of Spindle Speed(r.p.m):

-

1 - 400 r.p.m

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

IDA

-

Voltage:

-

customizable

-

Dimension(L*W*H):

-

500*400*400--1060*920*1060

-

Weight (KG):

-

380 KG

-

Marketing Type:

-

New Product

-

Roller diameter:

-

65-405mm

-

Length of roller working surface:

-

125-810mm

-

Output:

-

5-350L/h

-

Low speed roll:

-

14-26 r/min

-

Middle speed roll:

-

43-70 r/min

-

High speed roll:

-

133-205 r/min

-

Main motor power:

-

0.75-15kw

-

Machine weight:

-

85-5000kg

-

Certification:

-

CE

Quick Details

-

Output (kg/h):

-

0.5 - 50 kg/h

-

Feeding Size (mm):

-

10 - 20 mm

-

Output Size (mesh):

-

5 - 200 mesh

-

Power (kW):

-

3

-

Range of Spindle Speed(r.p.m):

-

1 - 400 r.p.m

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

IDA

-

Voltage:

-

customizable

-

Dimension(L*W*H):

-

500*400*400--1060*920*1060

-

Weight (KG):

-

380 KG

-

Marketing Type:

-

New Product

-

Roller diameter:

-

65-405mm

-

Length of roller working surface:

-

125-810mm

-

Output:

-

5-350L/h

-

Low speed roll:

-

14-26 r/min

-

Middle speed roll:

-

43-70 r/min

-

High speed roll:

-

133-205 r/min

-

Main motor power:

-

0.75-15kw

-

Machine weight:

-

85-5000kg

-

Certification:

-

CE

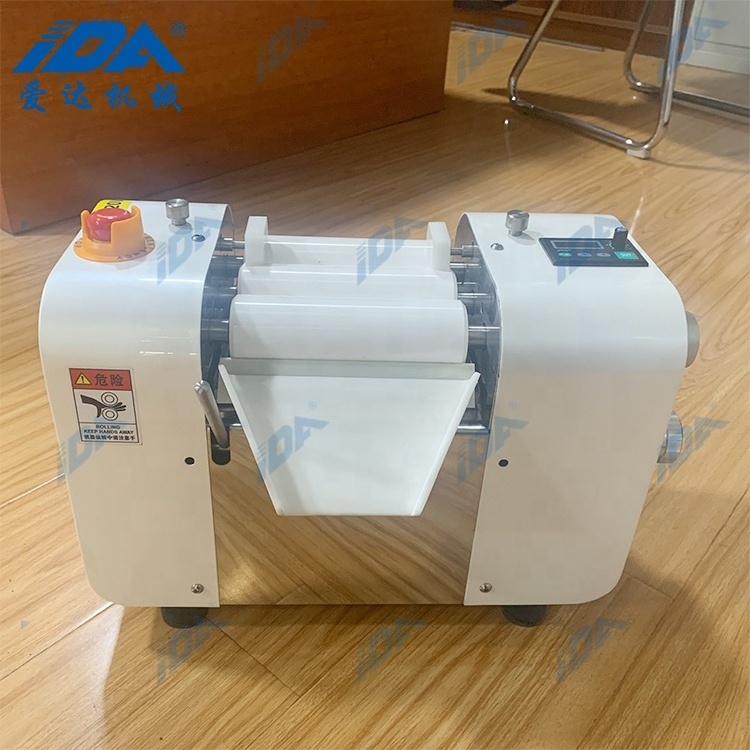

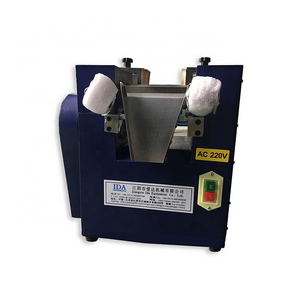

IDA Superfine series are high performance three roller mill, which created for hyper precise, narrow particle size distribution. She has an unparalleled reproducibility in nano grinding, which is best choice for Nano new material, Metal paste, Ceramic slurry, Electronics slurry, Cosmetics.

Working principle

The equipment consists of three rollers fixed on the frame and driven directly by the motor. The rotation direction between rollers is generally different, the front roller rotates forward while the rear roller rotates backward. The speed of front roller is quicker while speed of rear roller is slower. The middle roller is fixed, and the front and rear rollers are mounted on the slide with spring device. Adjust the distance between three rollers by adjusting the hand wheel. The material discharged from space between rear roller and middle roller, are squeezed by the rollers to obtain smaller particle size Then the material are rolled out by the fast roll(Roll rotates at high speed). The scrapper at the end of the fast roller separate material from the roller and fall into the collection barrels. Since it produces a lot of heat in the grinding process, the center of each roller is hollow. Input water for cooling to ensure finished products with good quality.

Main Features

1. Gap mode displays the gap distance value set by user and the actual stress values. (Unit: micron and Newton/ mm)

2. Clean mode and reverse function ensure the safety of operation.

3. Roller speed and distance can be set as a parameter (under any mode), up to 3,000 groups data.

4. Siemens PLC control brings easy and visual operation.

|

Model |

Superfine DS50 |

Superfine DS80 |

Superfine ES80 |

Superfine DS120 |

Superfine ES120 |

|

Roller diameter (mm) |

50mm |

80mm |

80mm |

120mm |

120mm |

|

Lenth of roller (mm) |

150/160mm |

200mm |

200mm |

450mm |

450mm |

|

Speed ratio |

1:2:4 |

1:3:9 |

1:3:9 |

1:3:9 |

1:3:9 |

|

Output(L/h) |

0.5~5 |

2~20 |

2~20 |

5~50 |

5~50 |

|

Motor power (KW) |

0.12KW |

1.5KW |

1.5KW |

3KW |

3KW |

|

Weight (kg) |

23kg |

75kg |

75kg |

380kg |

380kg |

|

Overall dimension(mm) |

390*250*280 |

720*550*550 |

720*550*550 |

1060*810*1060 |

1060*810*1060 |

It is widely used in CNT, High value metal paste, New Ceramic material, Electronics conductive paste,cosmetic,pigment,Solar pasty,etc.

2. Plastics film protection with standard sea packing

Shipping

1. Small parts: By express, TNT/ DHL/ UPS/ Fedex etc.

2. Full machine: By sea or By air

3.Choose the best suitable way as your need.

On-Sale Service: IDA factory will manufacture the good quality machine.

After-sale Service: IDA engineers will be sandby for 24 hrs to provide you with prompt solution. We could send technicians to your factory to help you install the disperser and sand mill, train your workers to operate and help with the debugging.

All wear parts of IDA disperser and sand mill is available at any time you need. Our engineer will provide you with spare parts scheme before sending the grinding mill to help you know when it is needed to change the parts so that to avoid any delay of production due to mill parts.