- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FONFAR

-

Dimension(L*W*H):

-

97*38*35cm

-

Weight:

-

42 KG

-

Product name:

-

Piston Liquid Cream Filling Machine

-

Material:

-

304 Stainless Steel

-

Filling material:

-

Flowing Liquid and Paste

-

Filling speed:

-

0-30bottles/min

-

Air pressure:

-

0.4-0.9 MPa

-

Air volume:

-

0.1M3/min

-

Accuracy:

-

±1%

-

OEM:

-

available

-

Capacity:

-

30L

Quick Details

-

Machinery Capacity:

-

2000BPH, 1000BPH

-

Packaging Material:

-

Glass, Metal, Paper, Plastic, Wood

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FONFAR

-

Dimension(L*W*H):

-

97*38*35cm

-

Weight:

-

42 KG

-

Product name:

-

Piston Liquid Cream Filling Machine

-

Material:

-

304 Stainless Steel

-

Filling material:

-

Flowing Liquid and Paste

-

Filling speed:

-

0-30bottles/min

-

Air pressure:

-

0.4-0.9 MPa

-

Air volume:

-

0.1M3/min

-

Accuracy:

-

±1%

-

OEM:

-

available

-

Capacity:

-

30L

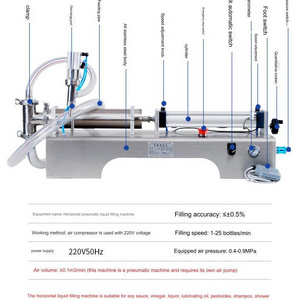

Semi-Automatic Horizontal Pneumatic Piston Filler /Liquid and Paste Dispenser for Oil Cream Lotion Honey Peanut Butter with CE

Products Description

Description

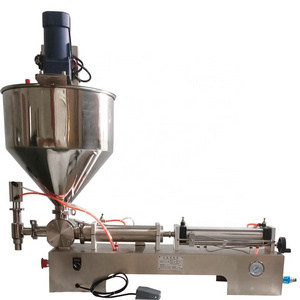

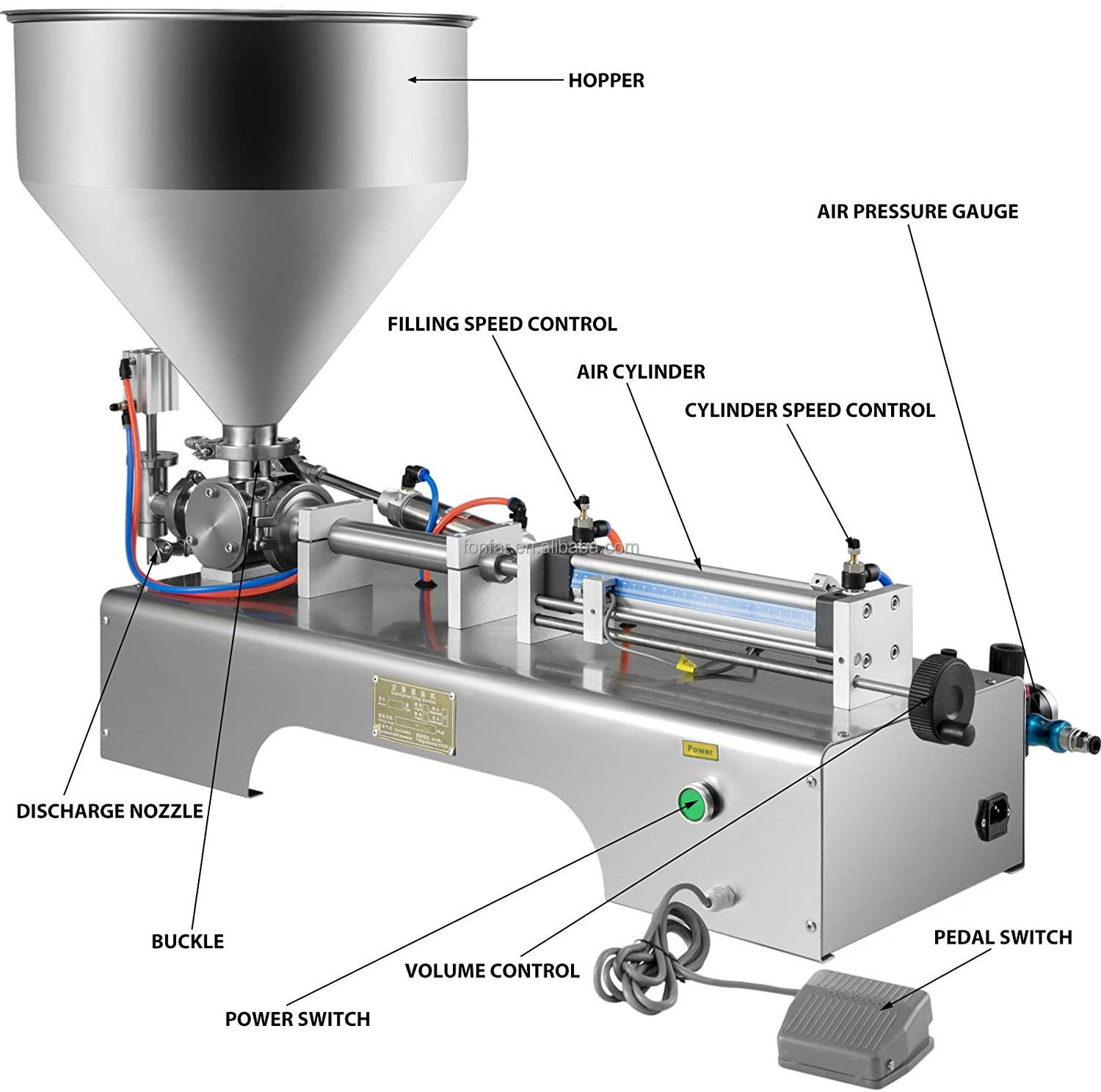

Paste filling machine is the automatic filling system using compressed air as power, which is composed of precision pneumatic components. The paste filling machine has the features of simple structure, reliable and convenient adjustment.

This paste filling machine also adapts to all kinds of paste, viscous paste filling. This paste filling machine can work in the inflammable and explosive environment. It is the ideal filling equipment of chemical, food, cosmetics and other industries.

Feature

1)Driven by a cylinder and piston made from materials with one-way valves control the flow of materials; Magnetic reed switch control cylinder itinerary can be regulated filling volume.

2)Rational design of the aircraft, model compact, easy to operate.

3)Advanced and high quality AirTAC pneumatic components.

4)Some contact materials are 316 L stainless steel materials, in line with the GMP

requirements;

5) Filling volume and speed of filling can be arbitrary regulated, high filling accuracy.

6) Widely used by industries of food & beverage, cosmetics, personal care, agricultural,

and chemistry.

7) An ideal device for paste and high viscosity liquid filling.

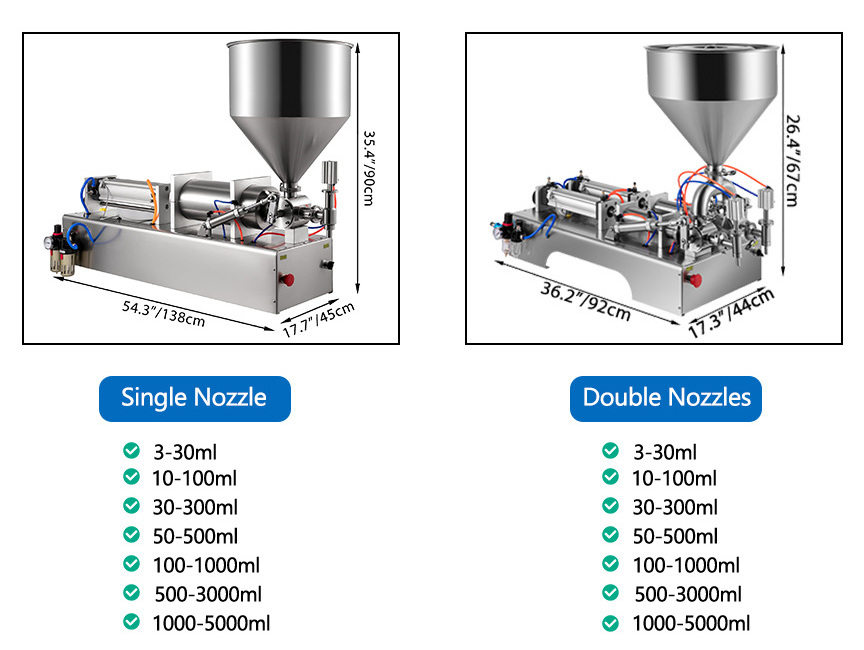

|

Model

|

G1WG-100

|

G1WG-300

|

G1WG-500

|

G1WG-1000

|

G1WG-3000

|

G1WG-5000

|

|||||

|

Filling Speed

|

10-30bottle/min

|

|

|

|

|

|

|||||

|

Filling range

|

10-100ml

|

20-300ml

|

50-500ml

|

100-1000ml

|

500-3000ml

|

1000-5000ml

|

|||||

|

Gross Weight

|

25kgs

|

28kgs

|

30kgs

|

33kgs

|

40kgs

|

55kgs

|

|||||

|

Packing Size

|

97*38*35cm

|

|

|

117*38*35cm

|

138*40*38cm

|

135*45*55cm

|

|||||

|

Hopper Size

|

45*45*45cm

|

|

|

45*45*55cm

|

|

|

|||||

|

Air Pressure

|

0.4-0.6mpa

|

|

|

|

|

|

|||||

|

Filling error

|

≤±1%

|

|

|

|

|

|

|||||

|

Voltage

|

220V/50HZ or 110V/60HZ(Optional)

|

|

|

|

|

|

|||||

The cylinder speed (filling pressure), filling speed, filling weight can be adjusted via the knobs on the cylinder. Cylinder speed will be slow down via knob in clockwise. In automatic model, make the filling speed a little longer in clockwise. The black handle knob can adjust the filling weight.

You can see the pressure on this part. The machine has to work with an air compressor 40L tank. The connection ID is 10mm.

Recommend Products

Package&Shipping

Hot Searches