- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

4500*1800*2400

-

Weight:

-

3000 KG

-

type:

-

printing machine for roll non woven bag

-

web width:

-

600-2000mm

-

print width:

-

560-1960mm

-

machiner speed:

-

general type doctor blade:100m/min;enclosed doctor blade:150m/min

-

print speed:

-

general type doctor blade:80m/min;enclosed doctor blade:130m/min

-

print length:

-

200-1100mm

-

anilox roller:

-

ceramic roller:100-1000LPI/cm,ink hold depth:3.5-10.5bcm

-

register precision:

-

±0.15mm(by hand)

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Xianghuai

-

Voltage:

-

380V

-

Dimensions(L*W*H):

-

4500*1800*2400

-

Weight:

-

3000 KG

-

type:

-

printing machine for roll non woven bag

-

web width:

-

600-2000mm

-

print width:

-

560-1960mm

-

machiner speed:

-

general type doctor blade:100m/min;enclosed doctor blade:150m/min

-

print speed:

-

general type doctor blade:80m/min;enclosed doctor blade:130m/min

-

print length:

-

200-1100mm

-

anilox roller:

-

ceramic roller:100-1000LPI/cm,ink hold depth:3.5-10.5bcm

-

register precision:

-

±0.15mm(by hand)

-

Certification:

-

CE

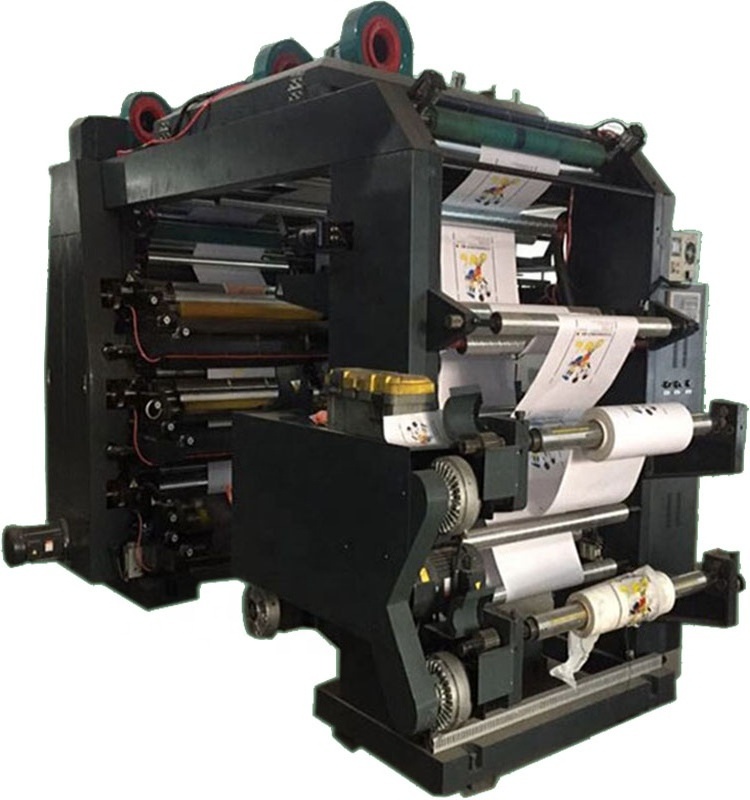

Multi Color Automatic Printing Machine

I. main parameter:

|

printing machine Model |

YTB-4600 |

YTB-4800 |

YTB-41000 |

YTB-41200 |

|

|

Printing Machine color

|

4color(4+0,3+1,2+2) |

4color(4+0,3+1,2+2) |

4color(4+0,3+1,2+2) |

4color(4+0,3+1,2+2) |

|

|

Max. Material Width |

600mm |

800mm |

1000mm |

1200mm |

|

|

Max. Printing Width |

560mm |

760mm |

960mm |

1160mm |

|

|

Printing Length |

200-1100mm |

||||

|

Printing Speed |

5-90m/min |

5-90m/min |

5-90m/min |

5-90m/min |

|

|

Max. Diameter of Roll Material |

Φ600 mm(Non woven, filmΦ1000mm) |

||||

|

Total Power |

18kw |

20kw |

22kw |

24kw |

|

|

Plate Thickness (including two-sided glue paper) |

2.38mm |

||||

|

Machine Weight |

4000kg |

4200kg |

4400kg |

4600kg |

|

|

Overall Dimension |

4.8*1.6*2.4m |

4.8*1.8*2.4m |

4.8*2.0*2.4m |

4.8*2.2*2.4m |

|

|

Working Voltage |

380V 3-phase 50Hz |

||||

|

Main Devices:

2) Air Shaft or general sharft

3) Ceramic Anilox Roller + General Doctor Blade 4) Motor(Taiwan) + Electric Parts (Siemens)

|

|||||

|

We retains the right to modify parameters without previous advice. |

|||||

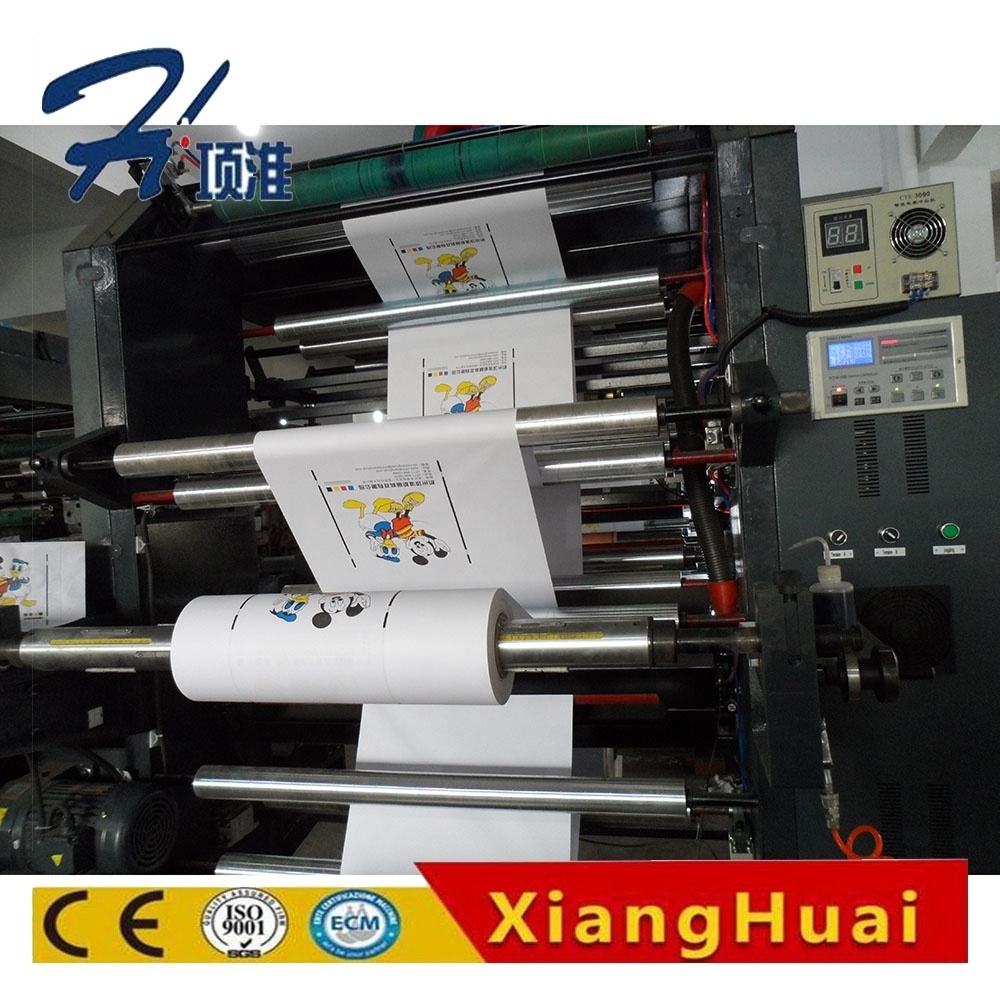

II . USE:

1) . The machine is used for BOPP,PET,PVC,PE Rolling Paper etc with good printing performance of rolling material for multi-color continuous printing.

2) . It is suitable for printing such packing materials as polyethylene, polypro-plane plastic bag, glass paper and

roll paper, etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes Bag, etc.

III. Suitable materials:

Roll Paper:

Kraft paper: 40 ~ 350g/m2, single-sided coated paper: 30 ~ 350g/m2, copy paper: 15 ~ 350g/m2, firecrackers and paper: 40 ~ 350g/m2

paper money and incense: 25 ~ 350g/ m2, silicone paper : 50 ~ 350g/m2, coated paper: 30 ~ 350g/m2, dust-free paper: 25 ~ 350g/m2

release paper: 40 ~ 350g/m2composite paper, 30 ~ 350g/ m2.

Roll Woven:

woven :15-120 grams,non woven :15-500 grams.

Roll Film:

PVC: 10 ~ 120μm, OPP: 10 ~ 100μm, BOPP: 10 ~ 100μm, PE: 15 ~ 150μm, NY: 10 ~ 120μm, PET: 10 ~ 100μm, CPP: 10 ~

100μm.

- Understand your needs

- Individual machine is designed upon user's need

- In-time service

- On-line / overseas technical support

- Fast delivery

- Always here for your service