- Product Details

- {{item.text}}

Quick Details

-

Seals:

-

Parker,NOK, BUSAK SHAMBAN, OPTIONAL

-

Temperature:

-

-30°C to 100°C

-

Mounting Style:

-

Flange Or Earing Mounting

-

Working Pressure:

-

7-35Mpa

-

Machining Roughness:

-

Max. Ra 0.4

-

Chemical Compositions:

-

spectrometer

-

Weight/Unit:

-

100kgs - 60 000kgs

-

Machining Tolerance:

-

Max. 0.01mm

-

Defect Control:

-

UT, MT, PT, RT

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TYHC or OEM or ODM

-

Material:

-

20#/45# Steel

-

Seals:

-

Parker,NOK, BUSAK SHAMBAN, OPTIONAL

-

Temperature:

-

-30°C to 100°C

-

Mounting Style:

-

Flange Or Earing Mounting

-

Working Pressure:

-

7-35Mpa

-

Machining Roughness:

-

Max. Ra 0.4

-

Chemical Compositions:

-

spectrometer

-

Weight/Unit:

-

100kgs - 60 000kgs

-

Machining Tolerance:

-

Max. 0.01mm

-

Defect Control:

-

UT, MT, PT, RT

Heavy Duty 5 Ton Servo Motor Electric Lift Cylinder With Waterproof Stainless Steel Cylinder Body

Product details:

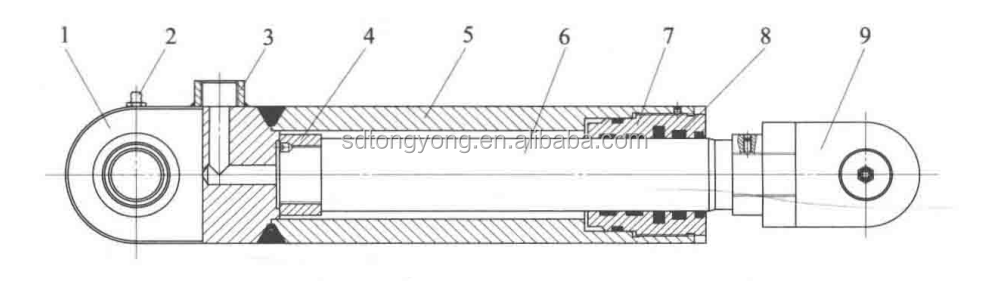

The roller cylinder is mainly used for the steering system of the roller. The product has the characteristics of compact structure and high reliability.

The cylinder cylinder is made of high-quality alloy steel after being scraped and rolled through the inner hole;

The piston rod is based on quenching and tempering, and the outer circle is coated with hard chrome to improve rust and wear resistance;

The seals adopt international famous brands that adapt to the working conditions of the main engine.

Technical parameters:

| Name | Unite | Power |

| Cylinders diameter (piston diameter) | mm | 50~140 |

| Rod diameter (piston rod diameter) | mm | 28~100 |

| Stroke | mm | 100~500 |

| Pressure | MPa | 16~25 |

| Operating temperature | ℃ | -40~120 |

| Piston rod coating NSS neutral salt spray test time | H | ≥96 |

Why choose us?

Meeting your hydraulic needs from design to delivery

We partner with our customers to design, engineer, and build custom hydraulic cylinders that work best for their specific application and industry. A tradition of craftsmanship, engineering excellence, quality control, and on-time delivery is included with all of our hydraulic cylinder products.

Tongyong Hydraulic have the advanced CNC machine tools, a horizontal machining center, a welding robot, parts cleaning agent, automatic assembly lines, automatic painting equipment etc. to hydraulic cylinder ensure a 360-degree quality control of the production process.

Rigorous Standards and Testing

We have been ISO Certified since 2004 and continually invest in our equipment and capabilities, with ongoing training for our most important asset – our people. This ensures that quality is built into each and every component of the hydraulic cylinders we manufacture.

Tongyong Hydraulic are passionate about delivering high-quality hydraulic cylinders which are fit for purpose, durable and long-lasting. In order to do this, we have invested in a dedicated assembly suite on-site at our facility. Our assembly area is secluded from our main manufacturing processes and all components are washed before assembly to maintain a good standard of cleanliness – ensuring that our cylinders perform to their fullest standard.

Prototype and Design Capabilities

As a full-service supplier, our team will be there for support from start to finish and will ensure a smooth launch into production, with dedicated ongoing support into the future.

Engineering Philosophy

Our sales and engineering staff will work with you to become an extension of your team. We will be there for support from start to finish for new or ongoing projects. We will work with you from the early design phase and application engineering and approvals through production and field support for the life of the product.

Through more than 35 years development, now we have 6 workshops,1 research center and 1 sales center. During the past years, we have accumulated rich experience and advanced technic, which make us can provide more better production and service.Our workshop occupy more than 36,800 square meters with 200 employees. There are 100 more sets of various high precision machines at our factory. Our production ability can reach max. 100,000 set each year. Delivery time can fully meet customer's requirement.Products are certificated by international ISO9001:2000.Third Party Inspection Institute SGS test orders for customers regularly and give high praise of our production. Now 60% of our production are exported. Our products are widely exported to the north and south America, Europe,Middle east,Africa Southeast Asia ,etc.