- Product Details

- {{item.text}}

Quick Details

-

Outer Diameter:

-

500mm-13000mm

-

Name:

-

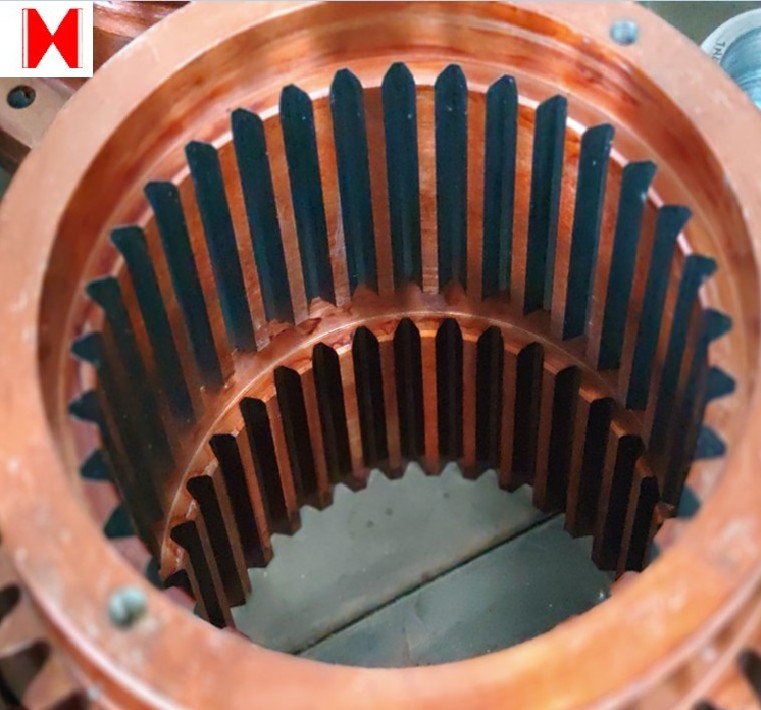

Forging Stainless Steel Crown Wheel Pinion Gear

-

Diameter:

-

2000-8000mm

-

Processing Type:

-

forging

-

After-sales Service Provided:

-

Proving overseas service from engineers

-

Weight:

-

10-200 T

-

Certificate:

-

ISO 9001:2000

-

Application Range:

-

metallurgy mine,petrochemical industry,lifting

-

Export Areas:

-

Russia, Southeast Asia, India,South Africa, Australia

-

Hardness:

-

<=HB217

Quick Details

-

Pressure Angle:

-

20

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HongXin

-

Outer Diameter:

-

500mm-13000mm

-

Name:

-

Forging Stainless Steel Crown Wheel Pinion Gear

-

Diameter:

-

2000-8000mm

-

Processing Type:

-

forging

-

After-sales Service Provided:

-

Proving overseas service from engineers

-

Weight:

-

10-200 T

-

Certificate:

-

ISO 9001:2000

-

Application Range:

-

metallurgy mine,petrochemical industry,lifting

-

Export Areas:

-

Russia, Southeast Asia, India,South Africa, Australia

-

Hardness:

-

<=HB217

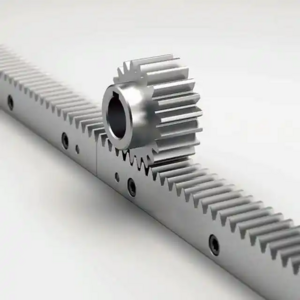

gear usage

|

Diameter

|

200-8000mm

|

|

Material

|

ZG35CrMo/42CrMo,steel,alloy,aluminum,carbon steel,cast iron or customized

|

|

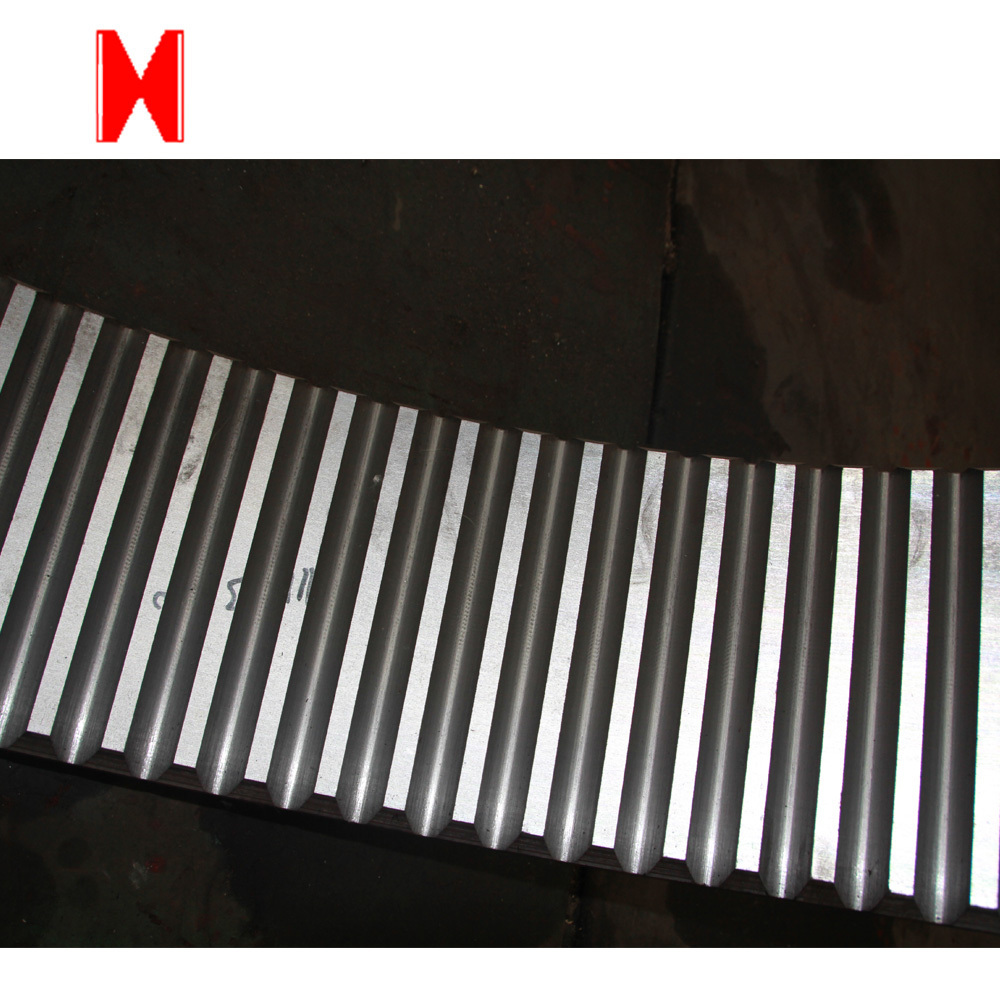

Processing Type

|

cast or forged

|

|

After-sales Service Provided

|

Proving overseas service from engineers

|

|

Application Range

|

Cement and mining facilities

|

|

Export Areas

|

Russia, Southeast Asia, India,South Africa, Australia

|

|

Hardness

|

197-560HBS

|

|

Package&Shipping

|

Wooden boxes,IPPC mark,coated with anti-corrosion oil,plastic inner lining,fixed with wood clamp,or according to customers' demand.

|

Testing

Depends on the products,

we make different Item Testing Plan,

different Manufacturing procedure etc.

Reports we provided for the products:

1) Chemical Composition Report

2) Mechanical Properties Report

3) Dimension Test Report

4) NDT Report

pakage details

2.do paiting if customer need it .

3.use white plastic film to pack the gears

4.put the gears into the wooden box.

5.

Bolt the gears into the box

6.

Wood reinforcement above the gears

7.cover the wooden case

8. shipping mark pinned outside the wooden box

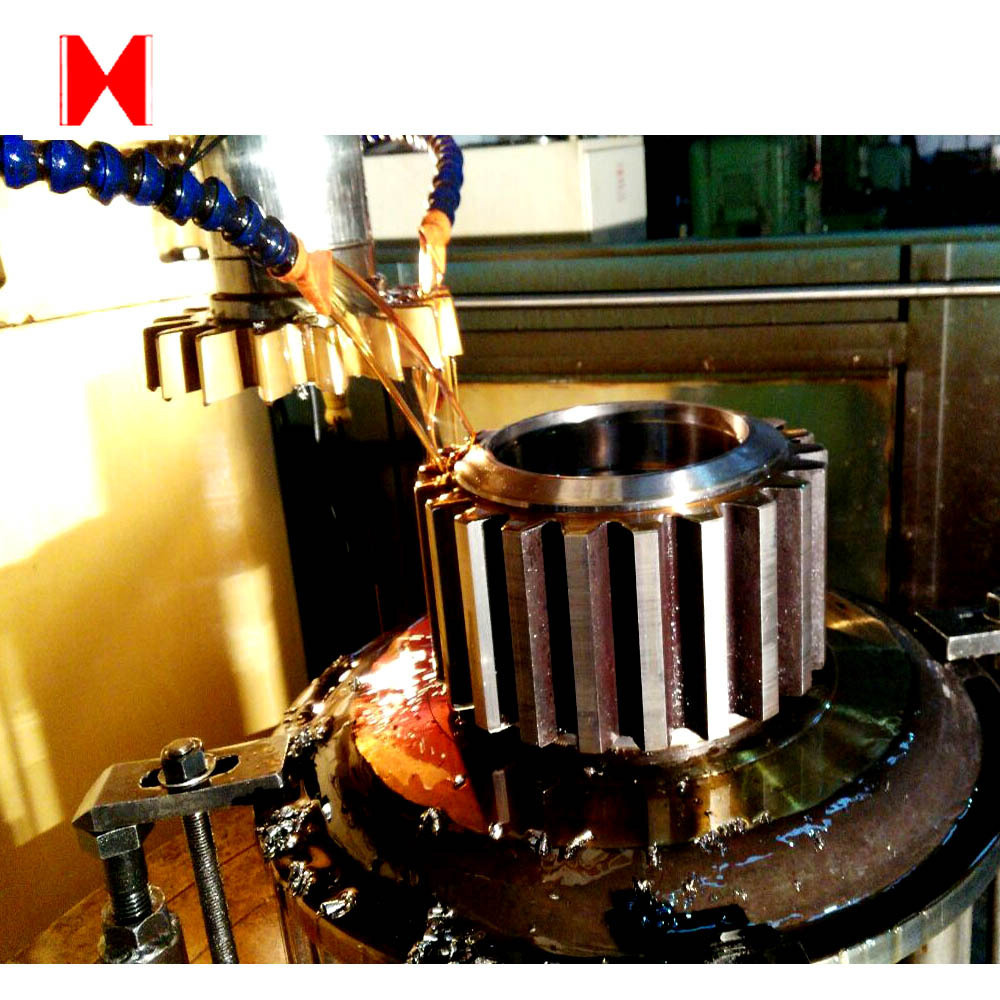

our CNC facility

we have all kinds of advanced CNC faclity

production process

Hot Searches