- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

50 - 150 mm

-

Ejector Number:

-

2

-

Ejector Stroke(mm):

-

30 mm

-

Ejector Force(kN):

-

5 kN

-

Theoretical Shot Volume(cm³):

-

30 cm³

-

Injection Rate (g/s):

-

50 g/s

-

Injection Weight (g):

-

30 g

-

Screw Speed (rpm):

-

1 - 220 rpm

-

Screw diameter (mm):

-

16 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

145mm*145mm

-

Weight (KG):

-

38.5 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

70 mm

-

Model Number:

-

HJK-10T

-

Brand Name:

-

HAIJIA

-

Power (kW):

-

0.75 kW

-

After-sales Service Provided:

-

Overseas third-party support available

-

Plastic injection moulding machine:

-

injection molding machine

-

Origin:

-

China

-

Injection Rate:

-

260mm/s

-

Injection Weight:

-

40g

-

Power(W):

-

0.5kw

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

Clamping Force (kN):

-

100kN

-

After Warranty Service:

-

Video technical support

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

110mm

-

Distance between Tie Bars(Height)(mm):

-

110mm

-

Plasticizing Capacity(g/s):

-

30

-

Mold Height(mm):

-

50 - 150 mm

-

Ejector Number:

-

2

-

Ejector Stroke(mm):

-

30 mm

-

Ejector Force(kN):

-

5 kN

-

Theoretical Shot Volume(cm³):

-

30 cm³

-

Injection Rate (g/s):

-

50 g/s

-

Injection Weight (g):

-

30 g

-

Screw Speed (rpm):

-

1 - 220 rpm

-

Screw diameter (mm):

-

16 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

145mm*145mm

-

Weight (KG):

-

38.5 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

70 mm

-

Model Number:

-

HJK-10T

-

Brand Name:

-

HAIJIA

-

Power (kW):

-

0.75 kW

-

After-sales Service Provided:

-

Overseas third-party support available

-

Plastic injection moulding machine:

-

injection molding machine

-

Origin:

-

China

-

Injection Rate:

-

260mm/s

-

Injection Weight:

-

40g

-

Power(W):

-

0.5kw

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

Clamping Force (kN):

-

100kN

-

After Warranty Service:

-

Video technical support

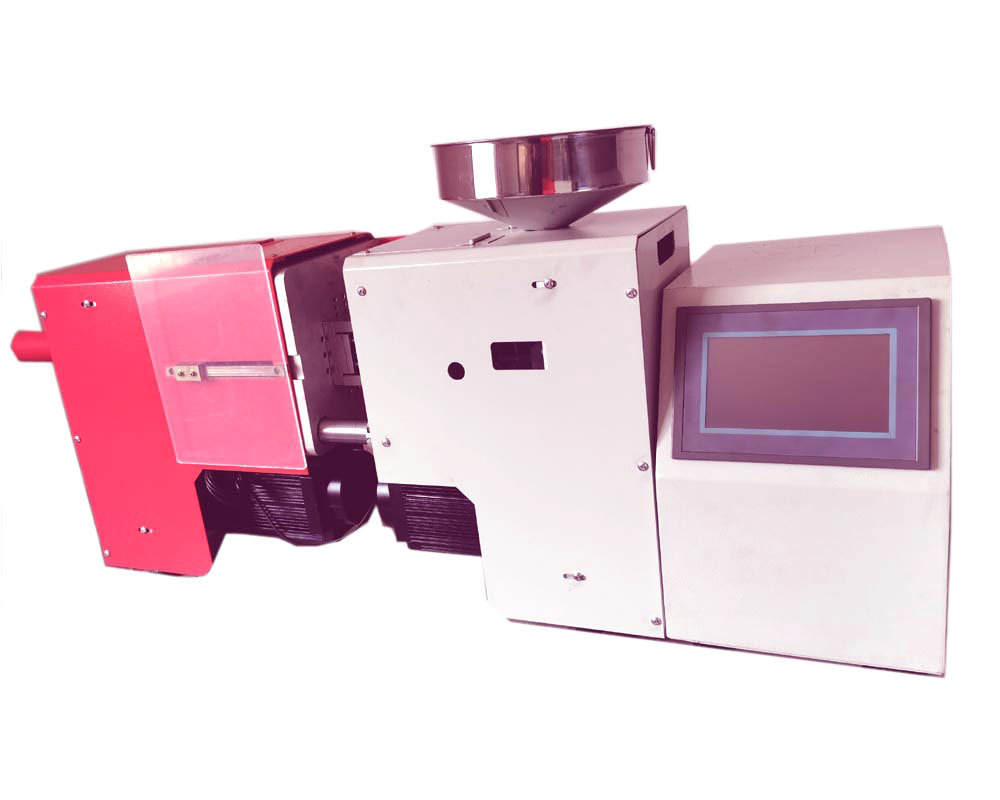

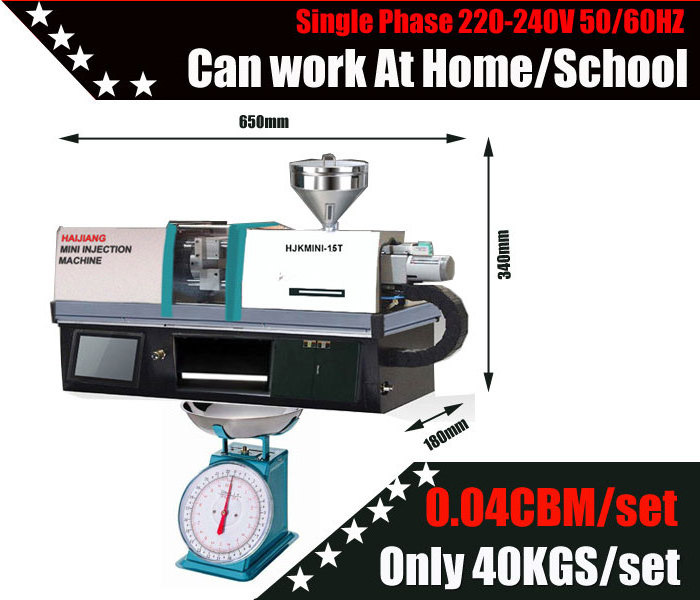

Mini desktop injection molding machine

Apply:

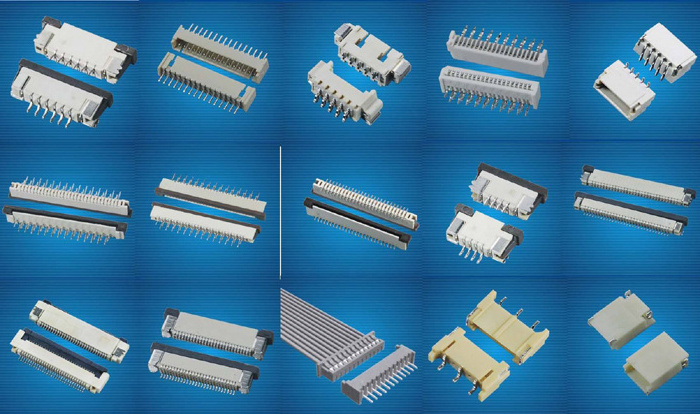

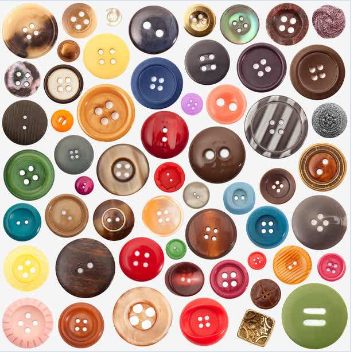

1.Micro precision parts production; 2.long-term or small orders;3.samples for testing ;4.air cleanliness workshop production ;5.for teaching and training;

pursuit the quality of products to be more stable

1.Ultra-high-sprformance dual-core CPU,computing speed 0.13us,shortest cycle control only62.5us,the machine is realized,high-speed and reliable operation,reduce consumption and costs,significantly improve the production efficiency.

2.The servo motor uses24-Bit MECHATROLINK-IIIbus of embedded NC technology yreatly improved plasticizing,injection sw;

3.The servo motor uses 24-Bit Absolute Type Encode,not only power failuer during operation or after power failure replacement of mechanical parts,but also to remember their locations in real time.

4,Server to utilize digital torque feedback control,plus the precision load measuing sensors,the machine can a chivev high accurac measuring the plasticizing;

Peripheral&Auxiliary Equipment

1.drying machine 2.automatic self-loader;3.water gap separator 4.cooling system;

|

Machine parameters |

||

|

Model Number |

HJKMINI-1.0T |

HJKMINI-1.5T |

|

Power |

0.5kw |

0.7kw |

|

Shot weight |

30 grams |

40 grams |

|

Nozzle hole Diameter |

2mm |

2mm |

|

Motor Accuracy |

0.002mm |

0.002mm |

|

Cooling Type |

Water |

water |

|

Power source |

AC220V |

AC220V |

|

Max Mold size |

180*110mm*110mm |

200*140*150 |

|

Heating Band Power |

DC36V |

DC36V |

|

Material |

PC,PS,PP,ABS,TPU |

PC,PS,PP,ABS,TPU |

|

Machine Size |

650mm*340mm*180mm |

650mm*340mm*180mm |

|

Machine weight |

40kgs |

45kgs |

Machine sieze:650mm*340mm*180mm

Machine weight:45 kgs

Suit for material: PS,PC,PP,ABS,PE,TPU

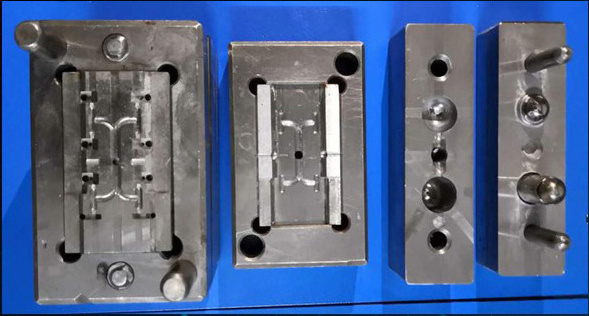

Mould: