- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3500*2500*2800

-

Year:

-

2019

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

37000 KG

-

Raw material:

-

Waste Tyre

-

Name:

-

Waste Tire Recycling Machine

-

Final product:

-

20-80 mesh powder

-

Capacity:

-

350-500kg/h

-

Application:

-

Rubber Processing Machinery

-

Keyword:

-

Waste Tire Powder Recycling

-

Function:

-

Tire Powder Recycling Machine

-

Keywords:

-

rubber powder making machine

-

Weight:

-

5t

-

Power(W):

-

73.5kw

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuliy

-

Voltage:

-

390v

-

Dimension(L*W*H):

-

3500*2500*2800

-

Year:

-

2019

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

37000 KG

-

Raw material:

-

Waste Tyre

-

Name:

-

Waste Tire Recycling Machine

-

Final product:

-

20-80 mesh powder

-

Capacity:

-

350-500kg/h

-

Application:

-

Rubber Processing Machinery

-

Keyword:

-

Waste Tire Powder Recycling

-

Function:

-

Tire Powder Recycling Machine

-

Keywords:

-

rubber powder making machine

-

Weight:

-

5t

-

Power(W):

-

73.5kw

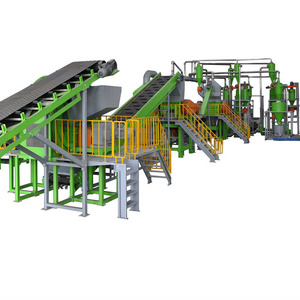

Waste Tyre Recycling Rubber Powder Making Machine

The waste rubber (tire) rubber powder production equipment is a new environmentally-friendly and energy-saving 800 alloy roller mill developed by Shuliy Machinery. The glue or steel tire block (wire steel tire block needs to be equipped with magnetic wire equipment) can be directly placed. The roller mill is automatically ground into 15-80 mesh rubber powder. After the screening, the rubber powder can be sold in bags. The rubber powder on the sieve can not be meshed and can be sent to the mill for grinding. The required number of meshes, one-stop production of complete equipment, combined with roller compaction, effectively control the pulverization temperature to ensure the quality of the pulverized material.

Parameter:

|

Model |

SL- 600 |

SL- 800 |

|

Feed size |

30-50mm |

30-50mm |

|

Out size |

10-80 finess |

10-80 finess |

|

power |

22kw |

30kw |

|

Capacity |

300-400kg/h |

|

Application:

Rubber products factory, reclaimed rubber factory, waterproof coil factory, runway, school playground, garden trail, bowling alley, sidewalk, composite rubber floor tile, anti-static floor tile, artificial lawn, playground, artificial grass soccer field, kindergarten sports ground And casino tennis and basketball courts. Rubber floor tiles, plastic track, lawn quartz sand, cottonseed granules, tennis courts, volleyball courts, golf courses, airplane courts, basketball courts and leisure casinos, EPDM safety mats, gym mats, all kinds of court mats.

Features:

1. It solves the problem of environmentally-friendly recycling and the use of rubber powder and rubber pellets produced by reprocessing and processing. Such raw materials have low cost and use value.

2. It is the continuous development of the new large-scale waste tire processing equipment in the machinery industry, which is more efficient and less costly in the process of use.

3. Complete separation: automatic separation of rubber, steel wire, nylon fiber and other materials;

4. Tool features: long life, high utilization, and can be maintained multiple times;

5. Security: humanized design, safe and secure;

6. Equipment features: a set of equipment to produce granules and rubber powder, can be customized according to customer requirements.

7. Processing wire truck tires can completely separate the steel wire from the rubber.