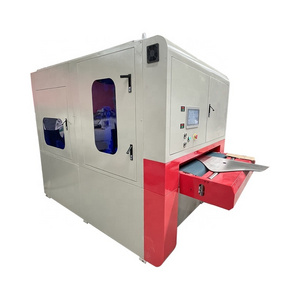

>About ADV 118 flat sheet polishing machine with abrasive belt, application laser cutting and punched parts, please tell us your material size range, then we can recommend the suitable machine to you.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

60

-

Model:

-

ZT 118-1

-

Maximum processing width:

-

20-90 mm

-

Maximum processing thickness:

-

1-60 mm

-

Grinding wheel diameter:

-

120 mm

-

Belt size:

-

920*100 mm

-

Main motor power:

-

2.2 kw

-

Feeding motor power:

-

180 w

-

Belt speed:

-

14m/s(Inverter option)

-

Feeding speed:

-

15 m/min

-

Machine size:

-

600*500*700 mm

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

ADV

-

Power (kW):

-

2.2

-

Weight (KG):

-

60

-

Model:

-

ZT 118-1

-

Maximum processing width:

-

20-90 mm

-

Maximum processing thickness:

-

1-60 mm

-

Grinding wheel diameter:

-

120 mm

-

Belt size:

-

920*100 mm

-

Main motor power:

-

2.2 kw

-

Feeding motor power:

-

180 w

-

Belt speed:

-

14m/s(Inverter option)

-

Feeding speed:

-

15 m/min

-

Machine size:

-

600*500*700 mm

We provide local services in below countries. And we are opening to have more agents.If you want to know whether your location has local service or not, please

click here.

Machine Description

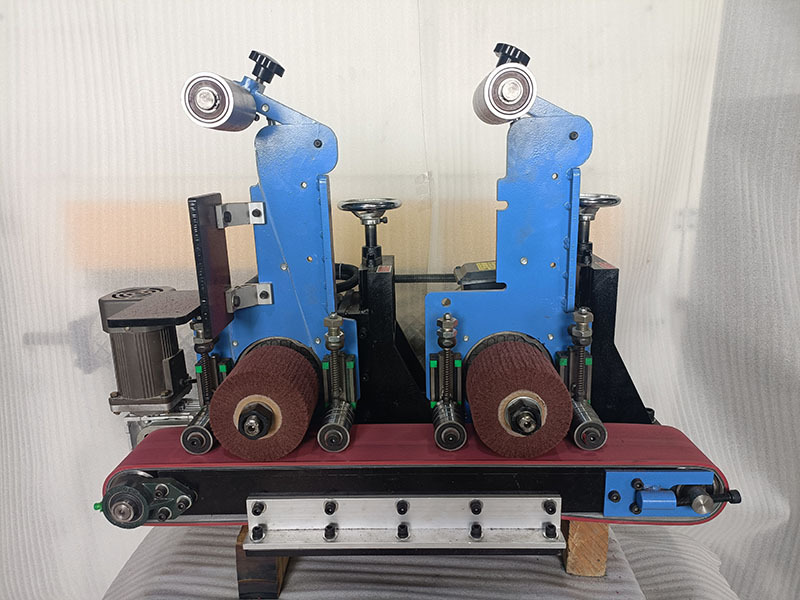

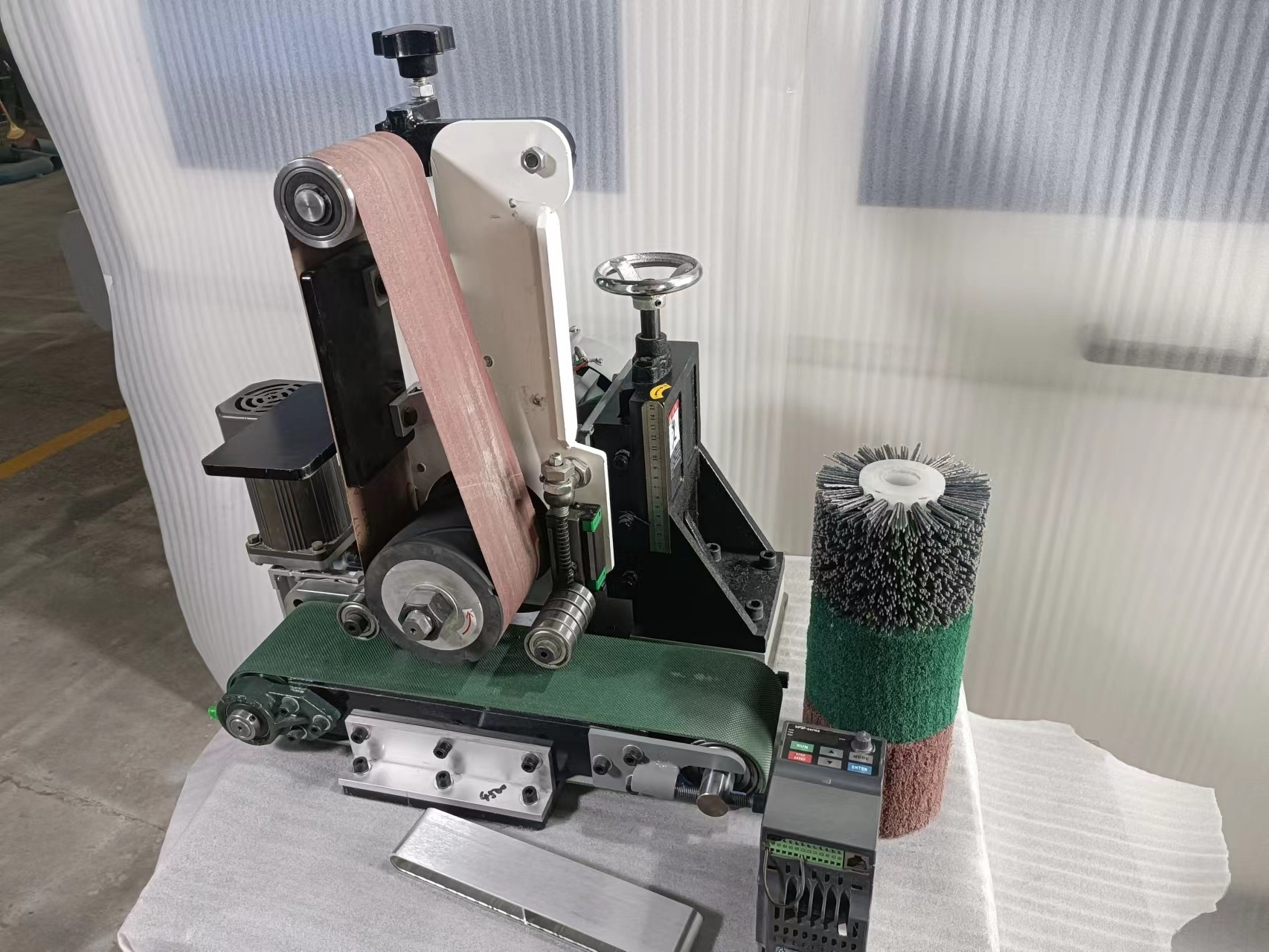

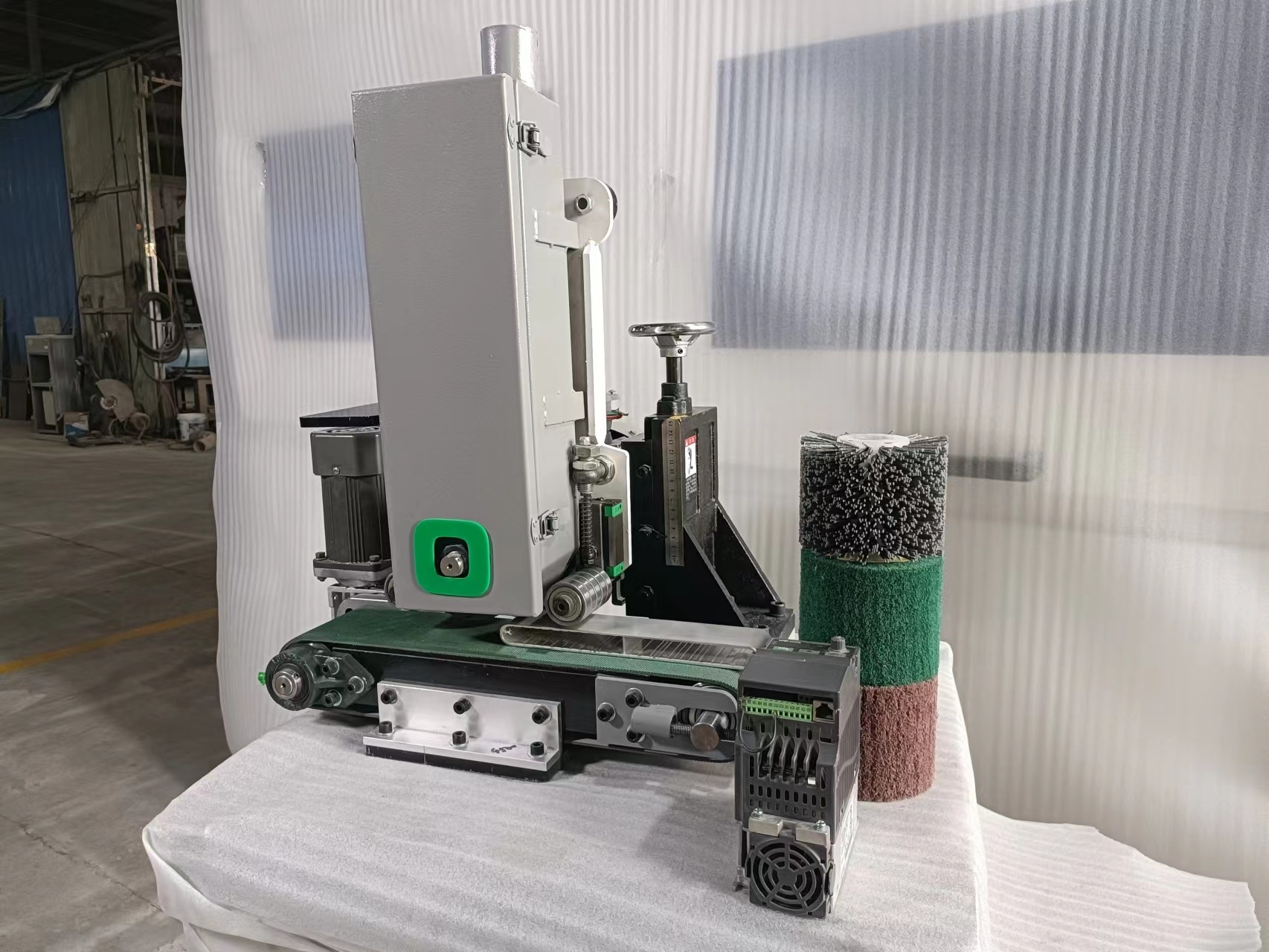

Tips:ADV 118-1small metal flat sheet polishing brushing machine

Reinforced workbench, 2.2kw pure copper wire motor, easy to replace with abrasive belt or brushed wheel, and can also grind cross-section

Machine Parameters

|

No

|

Item

|

Specification

|

|

1

|

Model

|

ZT 118-1

|

|

2

|

Product name

|

ZT 118-1 flat sheet polishing brushing machine

|

|

3

|

Main motor

|

2.2 kw

|

|

4

|

Feeding motor power

|

180w

|

|

5

|

Maximum processing width

|

20-90 mm

|

|

6

|

Maximum processing thickness

|

1-60 mm

|

|

7

|

Belt speed

|

14m/s(Inverter option)

|

|

8

|

Feeding speed

|

15m/min

|

|

9

|

Machine weight

|

60 kg

|

|

10

|

Machine size

|

600*500*700 mm

|

For more specification, please

contact us.

Machine Parts

ZT 118-1 flat sheet polishing machine with abrasive belt

ADV 118-1 flat sheet polishing polishing with brushed wheel

The multi-functional small plane belt polishing machine can replace the abrasive belt or brushed wheel according to the product requirements. The workpieces that need to be polished should be polished step by step with different meshes of consumables to achieve the effect.

No.4, hairline finish:

1.with sand belt to sweep the scratch line and sand-holes on the surface of the work piece(No.4 finish)

2.with the nylon wheel to get brushed effect. (hairline finish)

1.with sand belt to sweep the scratch line and sand-holes on the surface of the work piece(No.4 finish)

2.with the nylon wheel to get brushed effect. (hairline finish)

Consumables used: sand belt, nylon wheel.

Machine Application

Application materials

ZT 118-1 flat sheet polishing machine is suitable for stainless steel, steel, aluminium, copper, etc.

ZT 118-1 flat sheet polishing machine is suitable for stainless steel, steel, aluminium, copper, etc.

Application products:

Laser-cut, waterjet-cut and punched products

Application Industries:

ZT 118-1 flat sheet polishing machine are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

ZT 118-1 flat sheet polishing machine are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

We Support FREE Testing Samples for Customers

If you have any questions about the flat sheet polishing machine or other related questions, please contact us without

hesitation.

If you have any questions about the flat sheet polishing machine or other related questions, please contact us without

hesitation.

Hot Searches