- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ACC

-

Weight (T):

-

1000

-

mesh:

-

20-100mesh

-

motor:

-

optional

-

pipe material:

-

SS

-

material::

-

PVC/PP/PE/HDPE/ABS

-

machine:

-

plastic powder miller

-

type:

-

blade and disc

-

Power:

-

37-90KW

-

Capacity:

-

100-800KG/H

-

Style:

-

pvc pulverizer

-

Certification:

-

CE ISO

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Max.Production Capacity (kg/h):

-

350

-

Place of Origin:

-

China

-

Production Capacity (kg/h):

-

100 - 500 kg/h

-

Brand Name:

-

ACC

-

Weight (T):

-

1000

-

mesh:

-

20-100mesh

-

motor:

-

optional

-

pipe material:

-

SS

-

material::

-

PVC/PP/PE/HDPE/ABS

-

machine:

-

plastic powder miller

-

type:

-

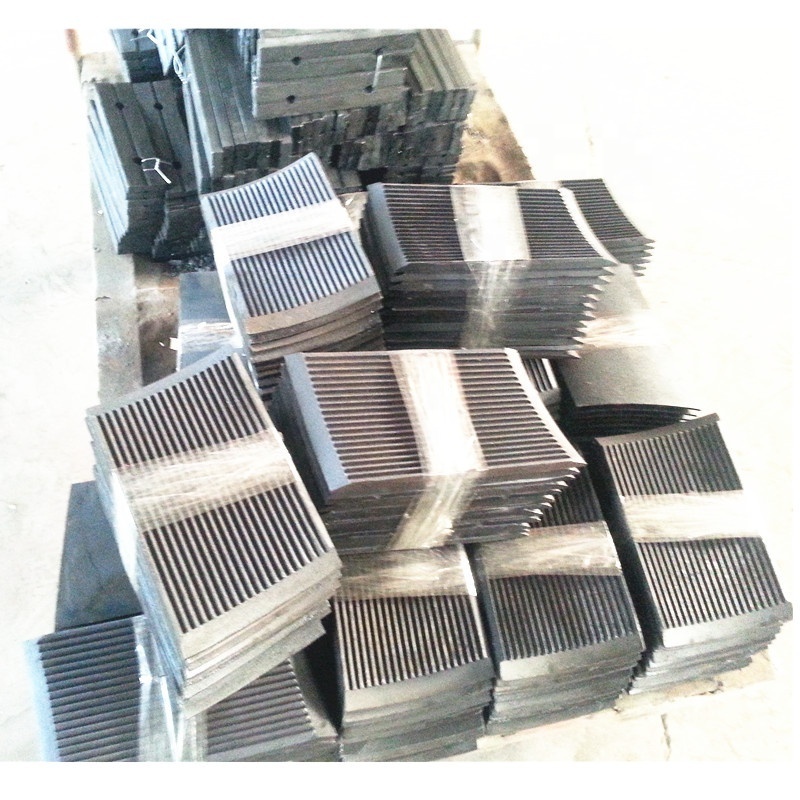

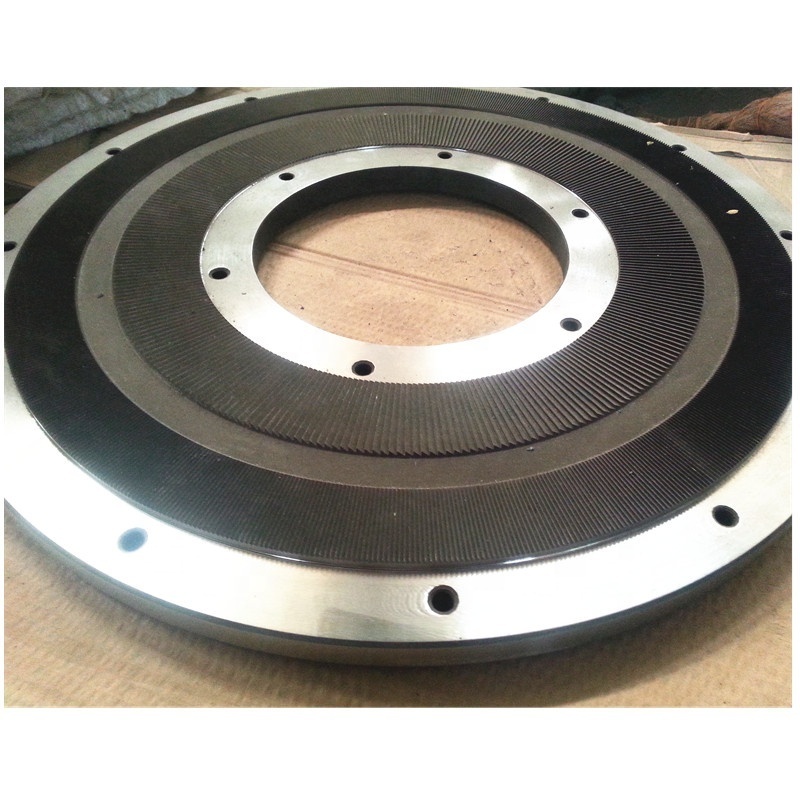

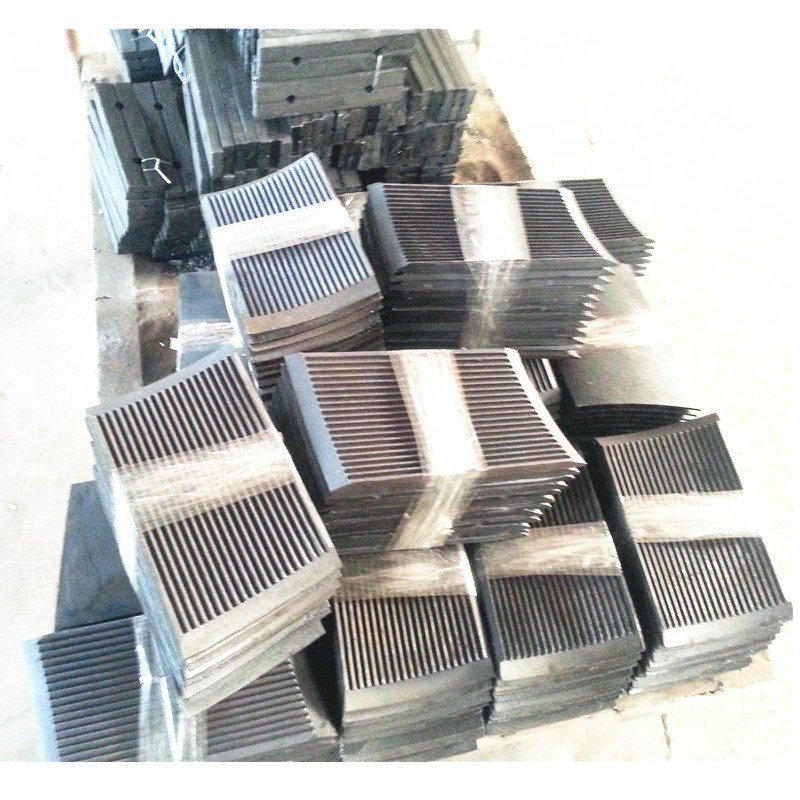

blade and disc

-

Power:

-

37-90KW

-

Capacity:

-

100-800KG/H

-

Style:

-

pvc pulverizer

-

Certification:

-

CE ISO

-

Marketing Type:

-

Ordinary Product

Product Description

Plastic miller/plastic pulverizer

Application : Suitable for recycle all kinds of grinding thermoplastic, like PP, PE, PVC,PET,EVA,ABS etc.

Advantages:

1.This type can grind all kinds Hard & Soft materials into 20-80 mesh powders in normal temperature

2.A widely use range, PVC/PE/PP/ABS/PS/PA/PC Materials

3.This machine has a more higher output, 2 or 3 times than normal miller, equip with Dust collector. An ideal energy saving machine in plastic industries

4.This miller includes automatic feeder, main engine, air fan conveying, cyclone separator, automatic shaker screen, auto coarse material milling again,high-efficiency dust collector system. Automatic and space saving.

5.The sword adopted imported stainless steel, durable, can work continous

6.Knife can be adjusted easily, easily maintained and control

7.Main shaft adopted SKF, matched with oil pump imported, can used about 3-4 years in normal use.

In plastic reprocessing after the types of plastic separated is a mechanical processing to run the plastic through the pulverizer. Pulverizer or pulveriser crushes the plastic into tiny shreds or granules. Plastic pulveriser is the particular equipment for recycling disused insignificant materials in producing and grinding heat-sensitivity plastic such as PVC.

Pulverizer includes high output units which can be equipped with automatic temperature control. The material to be pulverized is fed centrally between a fixed and a high speed rotating pulveriser disc with centrifugal effect carrying the material through the processing zone before being discharged from the machine pneumatically. This pulveriser is mainly used for lldpe , hdpe, rpvc material.

MP- series pulverizer machine specification(for PVC)

|

Model |

MP-500 |

MP-600 |

MP-800 |

|

Motor power (kw) |

37kw |

55kw |

75kw |

|

Blow power (kw) |

3kw |

5.5kw |

11kw |

|

Voltage |

380V, 50Hz |

380V, 50Hz |

380V, 50Hz |

|

Total power |

41kw |

52kw |

90.5kw |

|

Blade Dia. |

500mm |

600mm |

800mm |

|

Feeding material size |

Below 10mm |

Below 10mm |

Below 10mm |

|

Output size |

40-80mesh |

40-80mesh |

40-80mesh |

|

Vibration model |

ZDS-800 |

ZDS-1000 |

ZDS-1200 |

|

Capacity |

200-300kg/h |

300-500kg/h |

500-600kg/h |

|

Machine size(mm) |

2500*2000*3000mm |

3200*2600*3200mm |

3500*2400*4000mm

|