- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

5000 r.p.m

-

Max. Weight of Workpiece(kg):

-

enquiry us

-

Spindle Bore(mm):

-

enquiry us

-

Width of bed (mm):

-

0 mm

-

Spindle Motor Power(kW):

-

enquiry us

-

Max. Turned Length (mm):

-

330

-

Travel (X Axis)(mm):

-

330 mm

-

Travel (Z Axis)(mm):

-

360 mm

-

Positioning Accuracy (mm):

-

0.005

-

Repeatability (X/Y/Z) (mm):

-

0.002

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

1900*1460*1560/2700*1460*1560mm

-

Brand Name:

-

BLIN

-

Model Number:

-

BL-S36/36T

-

Weight (KG):

-

2300

-

Applicable Industries:

-

enquiry us

-

Automatic Grade:

-

Automatic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Max. swing dia. over bed:

-

500mm

-

Max. swing diameter over slide board:

-

275mm

-

Max.effective turning length:

-

320mm

-

spindle bore:

-

56/62

-

spindle type:

-

A2-6/A2-5

-

Turret type:

-

servo

-

Chuck size:

-

6''/8''

-

Machining roughness:

-

IT6

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

330

-

Year:

-

2024

-

Max. Spindle Speed (r.p.m):

-

5000 r.p.m

-

Max. Weight of Workpiece(kg):

-

enquiry us

-

Spindle Bore(mm):

-

enquiry us

-

Width of bed (mm):

-

0 mm

-

Spindle Motor Power(kW):

-

enquiry us

-

Max. Turned Length (mm):

-

330

-

Travel (X Axis)(mm):

-

330 mm

-

Travel (Z Axis)(mm):

-

360 mm

-

Positioning Accuracy (mm):

-

0.005

-

Repeatability (X/Y/Z) (mm):

-

0.002

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

1900*1460*1560/2700*1460*1560mm

-

Brand Name:

-

BLIN

-

Model Number:

-

BL-S36/36T

-

Weight (KG):

-

2300

-

Applicable Industries:

-

enquiry us

-

Automatic Grade:

-

Automatic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Max. swing dia. over bed:

-

500mm

-

Max. swing diameter over slide board:

-

275mm

-

Max.effective turning length:

-

320mm

-

spindle bore:

-

56/62

-

spindle type:

-

A2-6/A2-5

-

Turret type:

-

servo

-

Chuck size:

-

6''/8''

-

Machining roughness:

-

IT6

|

■ S36 mount gang tool device, S36T mount 8 station HYDRAULIC-SERVO tool turret.

|

|

|

|

|

||||

|

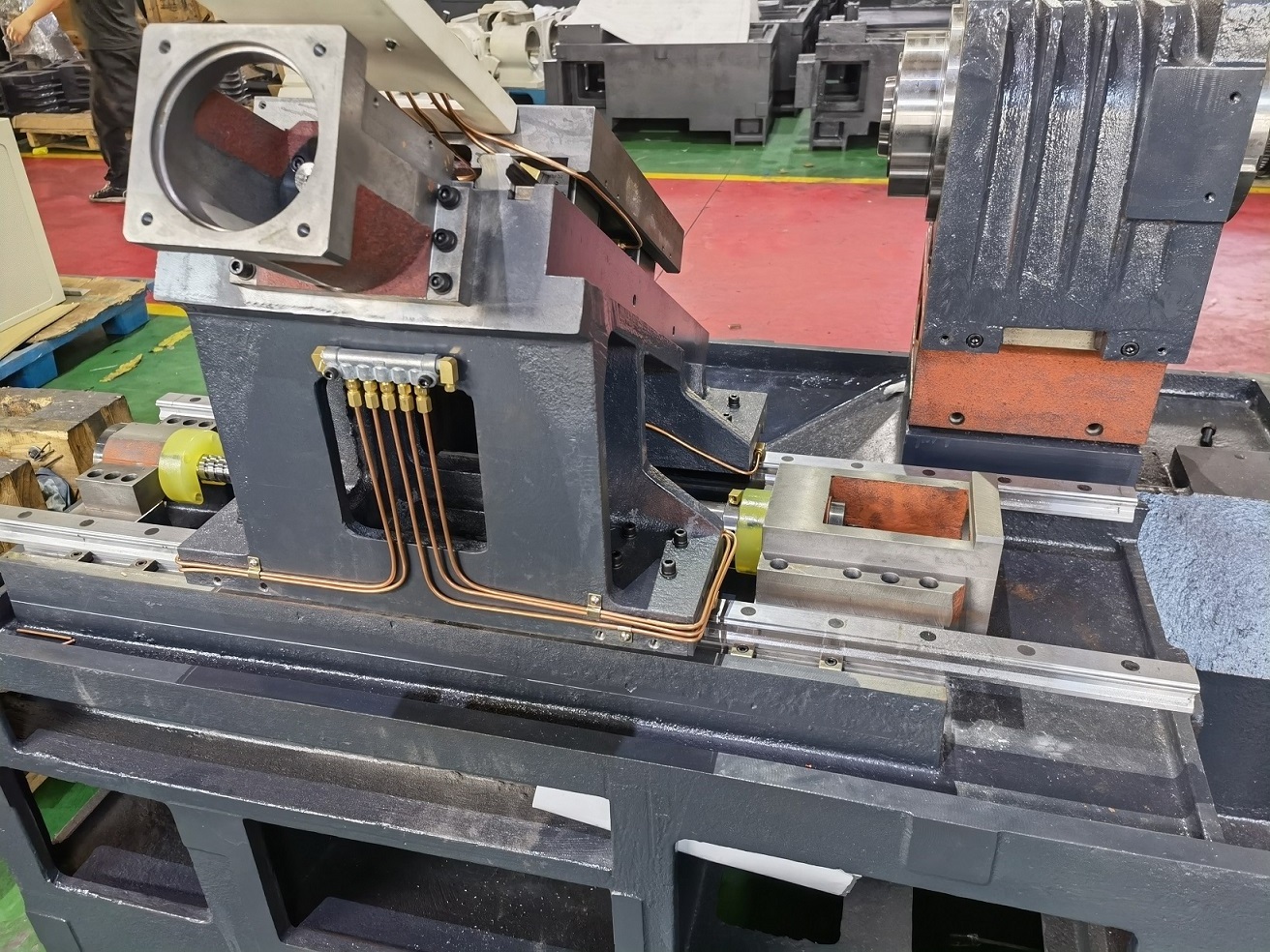

■ Super compact structure, big inside space, modern appearance

|

|

|

|

|

||||

|

■ Adopt TAIWAN technology, designed by TAIWAN engineer, most parts adopt GERMANY/JAPAN/TAIWAN brand.

|

|

|

|

|

||||

|

■ Bed adopt flat bed, slide board adopt 30°slant design(structure similar as JAPAN TSUGAMI M06/08), high rigidity,

good machining flexibility, easy for chip conveying |

|

|

|

|

||||

|

■ Adopt modularization design, has strong extended function, easy for various especial configuration choice, such as

tool setter, robot etc. |

|

|

|

|

||||

|

■ Adopt HT300 resin sand cast iron, after aging treatment and FEA analysis, small distortion, good torsional strength,

good heat stability. |

|

|

|

|

||||

|

■ Frame adopt oil-coolant separation design, adopt independent coolant tank

|

|

|

|

|

||||

|

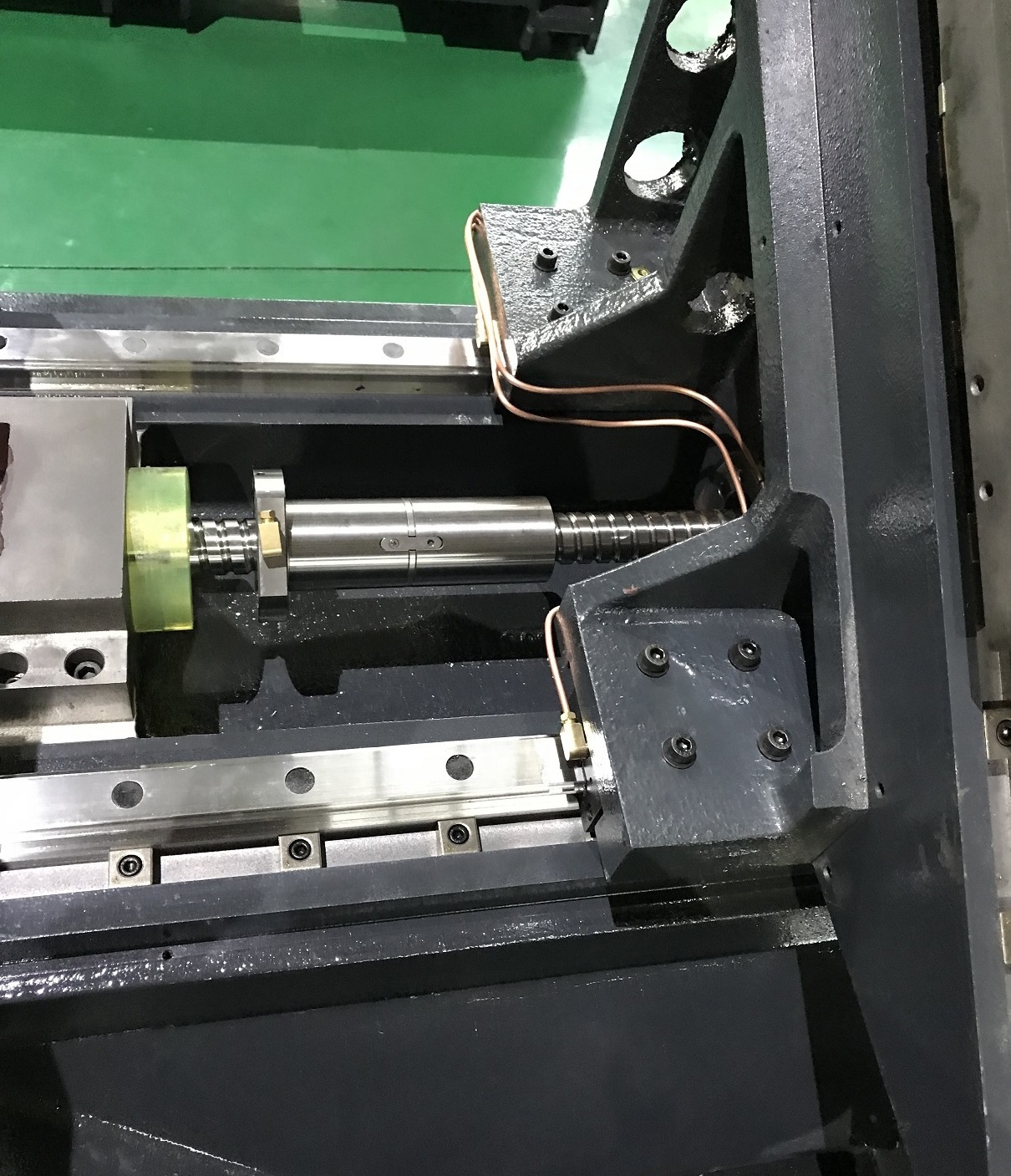

■ Adopt high precision integral spindle unit, spindle motor adopt high performance servo motor, big output torque,

high speed,wide adjustment range |

|

|

|

|

||||

|

■ Adopt high precision pre-stretched ball screw(double nuts), coupled with feeding motor directly by linkager, no gap,

high transmission rigidity, can realize μ class precise turning. |

|

|

|

|

||||

|

■ Adopt high precision wide linear guideway, high rigidity and long using lifespan, fast moving speed, good accuracy

holding, suitable for precise machining |

|

|

|

|

||||

|

■ For S36T, mount energy-storage tank,reduce pressure fluctuation during tool change

|

|

|

|

|

||||

|

■ Can mount right-setting or back-setting chip conveyor

|

|

|

|

|

||||

|

Item

|

Specification

|

Unit

|

BL-S36

|

BL-S36T

|

|

|

Capacity

|

Chuck size

|

/

|

6’’

|

|

|

|

|

Max. swing dia. over bed

|

mm

|

Φ460

|

|

|

|

|

Max. swing dia. over slide

|

mm

|

Φ130

|

Φ265

|

|

|

|

Max. turning length

|

mm

|

330

|

260

|

|

|

|

Max. turning dia.

|

|

Φ125

|

Φ360

|

|

|

Spindle

|

Spindle bore

|

mm

|

Φ56

|

|

|

|

|

Spindle end type

|

/

|

A2-5

|

|

|

|

|

Spindle speed

|

rpm

|

5000

|

|

|

|

|

Max. bar through dia.

|

mm

|

Φ44

|

|

|

|

|

Spindle motor power

|

kw

|

5.5

|

|

|

|

X/Z axes

|

X axes travel

|

mm

|

330

|

160+20

|

|

|

|

Z axes travel

|

mm

|

360

|

350

|

|

|

|

X/Z axes rapid moving speed

|

m/min

|

28

|

|

|

|

|

X/Z axes ball screw dia./pitch

|

mm

|

32/12

|

|

|

|

|

X/Z axes linear guideway width

|

mm

|

30/35

|

|

|

|

Tool turret

|

Tool turret type

|

/

|

Gang tool

|

Hydraulic-servo tool turret

|

|

|

|

Tool qty

|

/

|

5

|

8

|

|

|

|

Vicinal tool changing time

|

s

|

/

|

0.4

|

|

|

|

Farthest tool changing time

|

s

|

/

|

0.57

|

|

|

|

Toolshank size

|

mm

|

20×20, Φ25

|

|

|

|

Tailstock

|

Tailstock

|

/

|

N/A

|

|

|

|

Accuracy

|

Ex-circle finish turning accuracy

|

/

|

IT6

|

|

|

|

|

Finish turning roughness

|

mm

|

Ra0.4~1.6

|

|

|

|

|

Finish turning roundness

|

mm

|

≤0.003

|

|

|

|

|

Positioning accuracy(X/Z)

|

mm

|

0.005/0.008

|

|

|

|

|

Repeat positioning accuracy(X/Z)

|

mm

|

0.002/0.004

|

|

|

|

Others

|

Coolant pump power

|

w

|

180

|

|

|

|

|

Coolant flow

|

m³/h

|

3

|

|

|

|

|

Overall size

|

mm

|

1560×1500×1500/2360×1500×1500

(exclude/include chip conveyor)

|

|

|

|

|

N.W.

|

kg

|

2300

|

2400

|

|

Product Category

About Us

Packing & Shipping

Q1.Are you manufacturer or trading company?

A. We are professional machine tool manufacturer, we have total 3 manufacturers in CHINA and set export sales center & showroom in NINGBO city.

Q2. How about your price?

A. We have different series, covered high, middle, economical class with super high performance-price ratio. You may check with us for most suitable solutions.

Q3. Can you provide training for operation CNC machines?

A.Yes, free training in our factory is available.

Q4. What's your warranty terms?

A. We will supply a replacement for parts that prove to be defective for a period of one year (3 years for SIEMENS parts) , starting from one month after shipping date. Please contact us for more details.

Q5.Do you have CE certificate?

A. Yes,we have.

Q6. What’s the delivery time & package?

A.Depends on machine model and configuration. Normally not more than 45days. Please contact us to confirm. All our CNC machines are packed with sea worthy package.

Q7.What is MOQ?

A.1 Unit.

Homepage

Hot Searches