- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Rotexmaster

-

Voltage:

-

3 phase

-

Dimension(L*W*H):

-

2300x1430x1500cm

-

Power (kW):

-

132

-

Weight (KG):

-

5800 KG

-

Name:

-

biomass pellet mill line price

-

Raw material:

-

wood log,branch,wood chips,sawdust,EFB

-

Capacity:

-

1.5-2 t/h

-

Formation rate:

-

>99%

-

lubrication system:

-

automatic

-

Die materials:

-

stainless steel /alloy steel

-

mould type:

-

double-deck

-

Motor:

-

SIEMENS Brand

-

Control cabinet:

-

DELIXI

-

Power(W):

-

132kw

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

1500 - 2000 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Rotexmaster

-

Voltage:

-

3 phase

-

Dimension(L*W*H):

-

2300x1430x1500cm

-

Power (kW):

-

132

-

Weight (KG):

-

5800 KG

-

Name:

-

biomass pellet mill line price

-

Raw material:

-

wood log,branch,wood chips,sawdust,EFB

-

Capacity:

-

1.5-2 t/h

-

Formation rate:

-

>99%

-

lubrication system:

-

automatic

-

Die materials:

-

stainless steel /alloy steel

-

mould type:

-

double-deck

-

Motor:

-

SIEMENS Brand

-

Control cabinet:

-

DELIXI

-

Power(W):

-

132kw

Wood pelets line/wood pellet machine/ biomass pellet mill line price

whatsapp/wechat/mobile: 0086-15589939109 Email: vera ( at)rotexmaster.cn

| Wood pellet machine Biomass pellet mill line price Description |

|

|

| What kinds of material need biomass pellet mill line price ? |

| Wood log,Wood chips,sawdust, Palm fiber and EFB , Rice husk , Straw,Palm kernel shell..... |

|

| Parameter of biomass pellet mill line price | ||||||

| Model |

Power (KW) |

Pellet diameter (mm) |

Die diameter (mm) |

Output Capacity (t/h) |

Dimension (mm) |

Weight (t) |

| YGKJ560 | 132 | 6-12 | 560 | 1.5-2 | 2600*1300*2300 | 5.8 |

| YGKJ700 | 160 | 6-12 | 700 | 2-3 | 2900*1300*2400 | 7.8 |

| YGKJ880 | 220 | 6-12 | 880 | 3-4 | 2750*1650*3250 | 12 |

| Feature of biomass pellet mill line price |

|

1.Vertical hopper : This design can avoid the raw material be stuck in granulating room 2.Cooling system : As the pelletizing process will generate high temperature, it will lower the service life of die and bearing.Cooling system are considering this situation and avoid it happened. 3.Double-layer dies : This design increase the efficiency of pellet making,reduce clients cost. 4.Siemens frequency conversion motor : Sweden famous brand. 5.SKF bearing: Sweden famous brand, High precision, high speed, low noise, long span life. 6.Unique automatic lubricating system: Which lubricate the bearing, dies and rollers ,increase the produce efficiency and reduce energy consumption.It can work continuous 20 hours without stoping. 7.Roller High alloy steel, roller wrap adopt heat treatment 8. Mold: Stainless steel 9. heavy and stable machine foundation 10. Surface adopt stoving varnish painting |

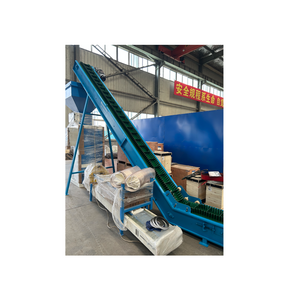

| Biomass pellet mill line price parts show |

|

| Biomass pellet mill line price Boday introduction |

| pellet line from wood chipper, hammer mill - wood pellets line -cooler: |

| Packing and loading of biomass pellet mill line price |

| About our Factory |

|

Shandong Rotex Machinery Co.,Ltd , Products related to environmental carbon, biomass dense compression molding equipment, urban and rural waste disposal equipment, organic fertilizer equipment, feed, breeding more than 200 varieties, Favored by domestic and foreign industry. The company has accumulated years of production experience in the design, based on further energy absorption and the introduction of foreign advanced technology manufacturing equipment, combined with the user's actual needs, and constantly improve and enhance the design, manufacturing philosophy, developed a highly efficient centrifugal biomass pellet mill line price, flat die pellet mill, ring die pellet mill, horizontal centrifugal granulator, pulverizer, wood splitting machine, peeling machine, wood machine, wood machine, peeling machine, large crushing machine, dryer, cooler , packaging machines and other flagship product. |

|

Our Team |

| RotexMaster attend Exhibition |

| RotexMaster Certificate |

| All our equipment, such as wood pellet machine, wood chipper, hammer mill, rotary dryer, packing machine, cooling equipment, feed equipment...all passed CE Certificate. Each equipment will be qualified before delivery in our factory. |

| FAQ |

|

1. Q: Are you manufacturer of trading company? A: We are manufacturer, also with marketing department and R&D center.

2. Q: I am newer to biomass industry, how to design the suitable plant? A: Do not worry about that. We already helped many beginners. We provide optimal project design according to every customer’s needs.

3. Q: Do you offer installation and training? A: Yes. We can dispatch technicians to customers’ site to help install equipment and train how to operate.

4. Q: How can you guarantee the after-sales service? A: We have professional After-sales service center with experienced and skillful engineers. When problem of equipment occurs, our engineers will be assigned to your site to solve problems timely. Also spare parts can be provided timely due to oversea warehouses.

5. Q: Which kinds of raw material can be used for making pellets? A:Sawdust (waste wood chips/shavings), other forest waste, agricultural straw, stalk, ,bamboo, peanut shells, rice husk, bagasse, alfalfa, palm fiber etc.

6. Q: What is the main process for making pellets? A: Coarse Crushing Section(Splitter, Wood Chipper)—Drying Section—Crushing Section—Pelletizing Section—Cooling Section—Packing Section |

| Contact Us |

|

WELCOME VISIT OUR FACTORY TO TESTING WOOD PELLET MAKING MACHINE AND DISCUSS MORE DETAILS FACE TO FACE. Moible phone/Wechat: 0086 15589939109 ( You can add my Whatsapp,Viber,Wechat by the phone number ) Skype:vera .rotex whatsapp/wechat/mobile: 0086-15589939109 Email: vera ( at)rotexmaster.cn Web: www.rotexpelletmill.com; www.pelletlinesolutions.com |