- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Decho

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

7.5m*1.6m*1.42m

-

Weight:

-

1500 kg

-

Product name:

-

billboard roll forming machine

-

Raw material:

-

pi ppgl

-

Thickness:

-

0.3--0.8mm

-

Main frame:

-

350H Steel

-

Color:

-

Client's Request

-

Shaft material:

-

High Grade No.45 Forged

-

Material of rollers:

-

45#steel Hard Chrome Coated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Coil width before rolling:

-

customized

-

Function:

-

billboard roll forming machine

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Decho

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

7.5m*1.6m*1.42m

-

Weight:

-

1500 kg

-

Product name:

-

billboard roll forming machine

-

Raw material:

-

pi ppgl

-

Thickness:

-

0.3--0.8mm

-

Main frame:

-

350H Steel

-

Color:

-

Client's Request

-

Shaft material:

-

High Grade No.45 Forged

-

Material of rollers:

-

45#steel Hard Chrome Coated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Coil width before rolling:

-

customized

-

Function:

-

billboard roll forming machine

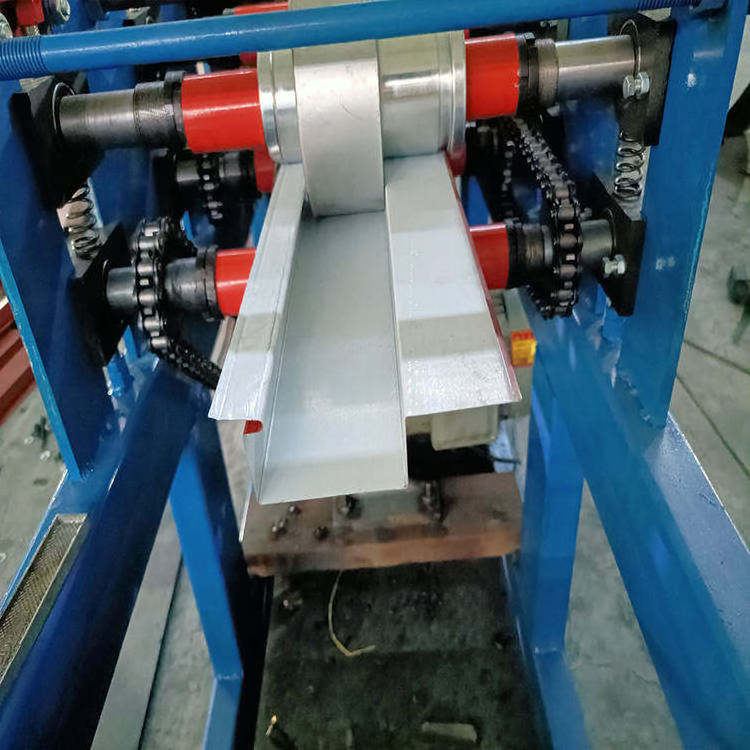

Details Images

Color steel gusset forming machine pictures:

Color steel gusset forming machine spare parts:

Product Specification

Trade Assurance European Standard C84 Adverting Gusset Plate Roll Forming Machinery

All can make customized for you!!!please let me know your all request,then,can share more details for you,please kindly contact with me!!!

All can make customized for you!!!please let me know your all request,then,can share more details for you,please kindly contact with me!!!

Make 3d metal wall panel to decorate rooms or advertising board

2.What is the function of the design Color steel gusset forming machine?

1).Simply operation

2).Advanced design of oil channels

3). Fast replacement of swallow-tail-shaped mould

4).High efficiency, reliable performance

2).Advanced design of oil channels

3). Fast replacement of swallow-tail-shaped mould

4).High efficiency, reliable performance

Packaging & Shipping

1. One container (20ft or 40ft ) for loading one set machine with manual decoiler and receiving rack.

2. The whole wiped Anti Rust Oil, PLC controller covered by foam film.

3. Spare parts and some small parts packed in plastic tooling box.

2. The whole wiped Anti Rust Oil, PLC controller covered by foam film.

3. Spare parts and some small parts packed in plastic tooling box.

Related Products

About Us

1.About Decho

Decho is a verified supplier by Alibaba and TUV .

We have 20 years of export experience serving global quality customers.Have a professional R&D team and technical engineers.Realize the integrated service from design to installation and commissioning.Our products provide customer more convenient in their business and expect to have more cooperate in future.

Main products are as follows:

|

Roofing forming machine

|

Purlin forming machine

|

Storage Rack System forming machine

|

|

Light steel keel forming machine

|

Floor decking forming machine

|

Shutter door forming machine

|

|

Highway Guardrall forming machine

|

Solar Panel Bracket forming machine

|

Truss roll forming machine

|

|

Channel roll forming machine

|

Ceiling roll forming machine

|

Slitter & cutter machine

|

|

Leveling & cutting machine

|

Bending machine

|

Decoiler (uncoiler)

|

2. Certificate

3. Customer Project

Project in Thailand

Project in India

Project in Russia

FAQ

Q1: Are you a manufacturer?

A1:Yes, we are professional manufacturer of the roll forming machine.

Q3. Can you provide OEM service for roll forming machine?

A3: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q4. How about the after-sale service?

A4: We provide 2-5 years free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q5:I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

A5: If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 -100 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

Q6: I receive a lot of quotations, they are big range, How could i choose?

A6: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for contacting with me.

Q7: I have not whatsapp and skype, how could I contact with you?

A7: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

Q8. If I am in Beijing, Shanghai or Guangzhou, how to visit your company?

A8: Please contact me and I will arrange a suitable itinerary for you.

A1:Yes, we are professional manufacturer of the roll forming machine.

Q2. What are the main key points for selecting right machines?

A2: Whole structure, Roller Shaft, Roller Material, Motor&Pump, and Control system. As the new buyer, please kindly know that price not the final point. Good quality is for long-term business cooperation.

A2: Whole structure, Roller Shaft, Roller Material, Motor&Pump, and Control system. As the new buyer, please kindly know that price not the final point. Good quality is for long-term business cooperation.

Q3. Can you provide OEM service for roll forming machine?

A3: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q4. How about the after-sale service?

A4: We provide 2-5 years free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q5:I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

A5: If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 -100 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

Q6: I receive a lot of quotations, they are big range, How could i choose?

A6: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for contacting with me.

Q7: I have not whatsapp and skype, how could I contact with you?

A7: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

Q8. If I am in Beijing, Shanghai or Guangzhou, how to visit your company?

A8: Please contact me and I will arrange a suitable itinerary for you.

Hot Searches