- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KADING

-

Dimension(L*W*H):

-

420x425x225cm

-

Weight:

-

14500 kg

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Semi-auto die cutting creasing machine

-

Model:

-

KPS

-

Origin:

-

Dongguang

-

Advantage:

-

Easy Operation

-

Usage:

-

Computer Paper Cutting Machine

-

Function:

-

Cardboard Die-cutting Machine

-

Application:

-

Cardboard box making

-

Feature:

-

Easy Opreation

-

Key words:

-

Flatbed Die Cutting Machine

-

Raw material:

-

Cardboard paper

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

Other

-

Max. workable width:

-

1600mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KADING

-

Dimension(L*W*H):

-

420x425x225cm

-

Weight:

-

14500 kg

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Semi-auto die cutting creasing machine

-

Model:

-

KPS

-

Origin:

-

Dongguang

-

Advantage:

-

Easy Operation

-

Usage:

-

Computer Paper Cutting Machine

-

Function:

-

Cardboard Die-cutting Machine

-

Application:

-

Cardboard box making

-

Feature:

-

Easy Opreation

-

Key words:

-

Flatbed Die Cutting Machine

-

Raw material:

-

Cardboard paper

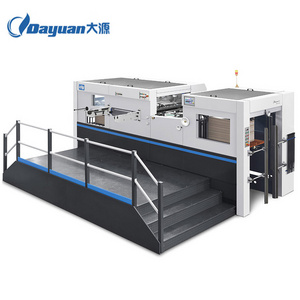

MACHINE DESCRIPTION

1.

KPS1300/1500/1650/2000 semi-automatic die-cutting and creasing machine is professional equipment for cutting offset printing box.

2.

There have high strength gripper,advanced open gripper structure that suitable for variety of cardboard and corrugated board; Front, back and side gauge assure the cutting precision.

3.

It also has intermittent mechanism with high precision, sensitive pneumatic clutch, pneumatic lock plate , PLC and HMI. Working speed, production account, total running time are all displayed by digital.

4.

The machine's breakdown display makes troubleshooting operations very convenient. It adopts the frequency converter control main motor, stepless speed regulation, smooth operation.

5.

There are equipped with many protection sensors to ensure the worker’s safety. What’s more, the front and back pressure can be adjusted individually, manual running is very convenient, die-cutting without clipper margin can be realized.

6.

The operation of die cutting part equipped with safety window and pneumaticlocking system.Air floation device make the pull out and push in of diecutting plate be moreeaslily.

DIE CUTTING PART&ELECTRIC PART

1.

The operation of die cutting part equipped with safety window and pneumatic locking system;

2.

Air floation device makes the pull out and push in of die cutting plate be more easily;

3.

The main electric parts are all world-renowned brands.

PNEUMATIC CLUTCH&MAIN CHAIN DRIVE

1.

Kading semi automatic die cutting and creasing machine adopts imported pneumatic clutch, with advantages like long service life, low noise, brake quickly with strong driving force. It is installed according to European exported standard.

2.

The main chain is imported from Britain that has a minimum error of length, high tensile and more wear-resistance.

MACHINE SPECIFICATION

|

Model

|

KPS-1300

|

KPS-1500

|

KPS-1650

|

KPS-2000

|

|

Max.paper size

|

1320X980mm

|

1510x1120mm

|

1670x1200mm

|

2000x1600mm

|

|

Min.paper size

|

350x450mm

|

450x500mm

|

500x550mm

|

600x600mm

|

|

Max.Die cutting size

|

1300x960mm

|

1490x1100mm

|

1650x1180mm

|

1970x1570mm

|

|

Min.gripper edge size

|

8mm

|

8mm

|

8mm

|

10mm

|

|

Max.Die-cutting pressure

|

350N/cm²

|

380N/cm²

|

400N/cm²

|

500N/cm²

|

|

Cardboard gram weight

|

200-2000g/㎡

|

200-2000g/㎡

|

200-2000g/㎡

|

200-2000g/㎡

|

|

Cardboard paper thickness

|

10mm

(Max.thickness)

|

10mm

(Max.thickness)

|

10mm

(Max.thickness)

|

10mm

(Max.thickness)

|

|

Max.Die-cutting speed

|

5000pcs/h

|

5000pcs/h

|

4200pcs/h

|

3800pcs/h

|

|

Max.Feeding pile height

|

1400mm

|

1400mm

|

1400mm

|

1400mm

|

|

Max.Collecting pile height

|

1250mm

|

1250mm

|

1300mm

|

1300mm

|

|

Total power

|

13.5kw

|

13.5kw

|

20kw

|

23kw

|

|

Weight

|

14.5T

|

18T

|

21T

|

25T

|

|

Dimensions(mm)

|

4200x4250x2250

|

4200x4300x2250

|

5200x4900x2250

|

6500x5050x2400

|

FAQ

Q: Are you a factory or a trading company?

A: We are a direct manufacturer that is located in Dongguang county, Cangzhou city. Welcome to visit our factory! We can also have video call if you’d like an online factory tour.

Q: How do you ensure your quality?

A: 1. Trustworthy and long-term cooperative raw material suppliers;

2. Skilled&experienced engineer&workers;

3. Mature QC system;

4. Specially-assigned merchandiser;

5. Advanced production workshop.

Q: How about your after-sale service?

A: 1. Special after-sale team will be 24/7 online;

2. Can guide the installation door-to-door;

3. One-year warranty for spare parts.

Q: How many languages does your machine support?

A: Our machine supports all the languages.

Q: How long it will take to produce machine?

A: Delivery time largely depends on the machine type, for some small machine like manual stitching machine, manual banding machine etc, usually we have stock available. But for the large machines like carton printing die cutting machine, automatic stitching machine etc, it usually takes around 35-50 days to produce.

Q: Can we visit your factory?

A: Sure, welcome to pay a visit for our factory, we will pick you up from airport, and will provide accommodation.

A: We are a direct manufacturer that is located in Dongguang county, Cangzhou city. Welcome to visit our factory! We can also have video call if you’d like an online factory tour.

Q: How do you ensure your quality?

A: 1. Trustworthy and long-term cooperative raw material suppliers;

2. Skilled&experienced engineer&workers;

3. Mature QC system;

4. Specially-assigned merchandiser;

5. Advanced production workshop.

Q: How about your after-sale service?

A: 1. Special after-sale team will be 24/7 online;

2. Can guide the installation door-to-door;

3. One-year warranty for spare parts.

Q: How many languages does your machine support?

A: Our machine supports all the languages.

Q: How long it will take to produce machine?

A: Delivery time largely depends on the machine type, for some small machine like manual stitching machine, manual banding machine etc, usually we have stock available. But for the large machines like carton printing die cutting machine, automatic stitching machine etc, it usually takes around 35-50 days to produce.

Q: Can we visit your factory?

A: Sure, welcome to pay a visit for our factory, we will pick you up from airport, and will provide accommodation.

Hot Searches