- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v 50hz 3Phase or Customized

-

Dimension(L*W*H):

-

About 3000*1500*1800mm(ACS300/80)

-

Power (kW):

-

103-171

-

Weight:

-

2000

-

Screw Speed (rpm):

-

1 - 600 rpm

-

color:

-

Customize as needed

-

Host motor power:

-

45kw-4 level/55kw-4 level/30kw-6 level/30kw-4 level

-

Sub-motor power:

-

22kw-4 level/11kw-4 level

-

Size of host screw:

-

125*2400mm/125*2200mm/147*2500mm

-

Size of sub machine screw:

-

125*1000mm/136*1200mm

-

Sinks:

-

3000*400*240mm

-

Receiving hopper:

-

950*680*450mm

-

Granulator:

-

3kw motor/4kw motor

-

Function:

-

Granulating machine for old plastics

-

Size can be customized:

-

Size can be customized

Quick Details

-

Output (kg/h):

-

150 - 1200 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Quanshun

-

Voltage:

-

380v 50hz 3Phase or Customized

-

Dimension(L*W*H):

-

About 3000*1500*1800mm(ACS300/80)

-

Power (kW):

-

103-171

-

Weight:

-

2000

-

Screw Speed (rpm):

-

1 - 600 rpm

-

color:

-

Customize as needed

-

Host motor power:

-

45kw-4 level/55kw-4 level/30kw-6 level/30kw-4 level

-

Sub-motor power:

-

22kw-4 level/11kw-4 level

-

Size of host screw:

-

125*2400mm/125*2200mm/147*2500mm

-

Size of sub machine screw:

-

125*1000mm/136*1200mm

-

Sinks:

-

3000*400*240mm

-

Receiving hopper:

-

950*680*450mm

-

Granulator:

-

3kw motor/4kw motor

-

Function:

-

Granulating machine for old plastics

-

Size can be customized:

-

Size can be customized

Product Overview

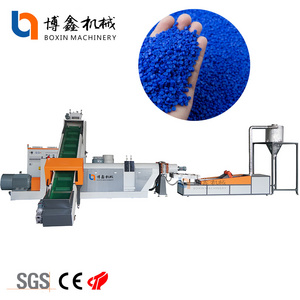

The main part of the two-stage plastic granulator

This picture shows the main part of a two-stage plastic pelletizer. This part takes the role of plastic heating and melting and extrusion.

Suitable processing objects

Product structure and function introduction

This machine adopts double-stage main and sub machine structure, with double-layer filtering function, which can remove impuritie scontained in the return material more effectively.

This machine can fully exhaust and make the plasticization more uniform. Eliminate the phenomenon of material sticking to the wall, reduce the labor intensity of workers, and greatly extend the service life of the equipment.

It has the characteristics of high output and low energy consumption. It is worth noting that the plastic pellets produced by this machine are firm, full and lustrous.

High power motor to provide stable power for the whole set of pelletizing equipment.

Electrically heated sub machine mold head for more uniform plasticization of finished products.

The main machine and sub machine are equipped with filtering device to filter out the impurities in the melt, which makes the finished particles more pure and shiny.

Warm Tips

How to understand old plastic

Old plastic is a colloquial term that does not refer to waste, useless plastic products. The vast majority of plastic products,especially single-use plastic products, do not have major changes in the properties of their plastic materials after use and can be fully recycled, processed in appropriate ways, and used again. Therefore, the more formal term for old plastic is post-consumer plastic waste.

Types of plastics for which this series of machines is suitable

This machine can be used for pelletizing PP PE PT ABS PS PVC PET/PETP EPS HDPE LDPE 、Hard Plastic Products、Soft Plastics Products and other types of plastics.

Friendly reminder

If you would like to learn more information, please send an inquiry or TM for inquiry, and I will answer your questions.

You can also add my Whats app、We chat、X、Gmail at the bottom of this page.

You can also add my Whats app、We chat、X、Gmail at the bottom of this page.

|

Specification parameters

|

|

|

|

|

||||

|

Product Name

|

Two-stage plastic pelletizing machine

|

|

|

|

||||

|

System Components

|

Crawler Feeder/Plastic Crusher/ Vertical mixing cylinder/ Feeding conveyor/Plastic pelletizing machine/Cooling water tank/Granulator/Vibrating granule sifter/Storage cylinder

|

|

|

|

||||

|

Target crushing material

|

PP, PE, PT, ABS, PS, PET, PVC and other types of plastics

|

|

|

|

||||

|

Final Product Shape

|

Particles

|

|

|

|

||||

|

Host machine model

|

125H

|

125S

|

150H

|

150S

|

||||

|

Screw Diameter(mm)

|

125

|

125

|

147

|

147

|

||||

|

Screw Length(mm)

|

2400

|

2200

|

2500

|

2500

|

||||

|

Motor Power(kw)

|

30kw-6 level

|

30kw-4 level

|

55kw-4 level

|

45kw-4 level

|

||||

|

Speed Reducer

|

JZQ500

|

JZQ500

|

JZQ600

|

JZQ600

|

||||

|

Production Capacity (kg/h)

|

150-250

|

150-200

|

250-350

|

200-300

|

||||

|

Heating Method

|

Induction heating

|

Induction heating

|

Induction heating

|

Induction heating

|

||||

|

Material port heating ring

|

73*100*1kw*2

|

73*100*1kw*2

|

89*100*1kw*2

|

89*100*1kw*2

|

||||

|

Sub machine model

|

125H

|

125S

|

150H

|

150S

|

||||

|

Screw Diameter(mm)

|

125

|

125

|

136

|

136

|

||||

|

Screw Length(mm)

|

1000

|

1000

|

1200

|

1200

|

||||

|

Motor Power(kw)

|

11kw-4 level

|

11kw-4 level

|

22kw-4 level

|

22kw-4 level

|

||||

|

Speed Reducer

|

JZQ400

|

JZQ600

|

JZQ600

|

JZQ600

|

||||

|

Production Capacity (kg/h)

|

150-250

|

150-200

|

250-300

|

200-300

|

||||

|

Heating Method

|

Induction heating

|

Induction heating

|

Induction heating

|

Induction heating

|

||||

|

Sub machine mold head heating ring

|

360*60*3kw*1

|

360*60*3kw*1

|

410*60*4kw*1

|

410*60*4kw*1

|

||||

Product structure and function introduction

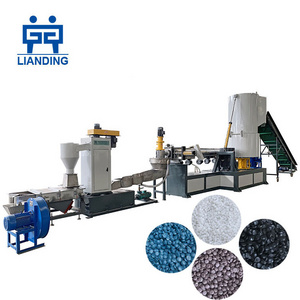

Main view of two-step plastic granulator

Customized according to your requirements

Main view

Electric heating

Double side filter mechanism

Automation

Material crushing

Recycled waste

plastics into the

crusher crushing.

Feeding and

compaction

The material crushed by the crusher enters the main machine barrel; the main machine barrel heats and melts the material; the preliminary melted material enters the secondary machine barrel; the secondary machine barrel is melted again to ensure that the material is heated evenly and plasticized well.

Melt filtration

The main machine and sub machine are equipped with filtration device, which can filter out the impurities in the melt.

Extrusion system

The extrusion die of the sub machine can extrude the plastic strip in molten state and enter the subsequent cooling pool.

Drying system

Blowing machine to remove water and dry the extruded strips.

Pelletizing system

Applicable to most common waste plastics, it is a widely used recycling processing machine in the waste plastics recycling industry. The extruded hot melt plastic strips are cut into granules for operation, and the granules are full and shiny.

Sub machine heating mold head

Oblique close-up

Sub machine heating mold head

Side close-up

Sub machine heating mold head

Rear close-up

Other machinery you may like

Plastic Crushers and Foam Crushers

Plastic granulators

integrated machine

Two-stage

plastic granulators

Three-stage

foam granulators

Foam cold press recovery machine

Feeder Loaders

Storage steel barrels

Plastic grain cutting machine

Vibrating granule sifter

Crawler Feeder

Cooling sink

Double Shaft Foam Crusher

Horizontal Dewatering Machine

Loading and Logistics

Kind reminder

The prices and parameters displayed on this webpage are only the prices and parameters of some models produced by our company. If

you would like to know more price information, please click "Send Inquiry" to contact us.

Due to the time difference, we suggest that you choose "Send inquiry" instead of "Chat now".

It would be great if you could provide us with your commonly used contact information when sending us inquiries or messages, so that our sales manager can quickly contact you.

You can contact us through the above methods

Plastic pelletizing whole process diagram

Hot Searches