- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Guanzhuo

-

Model Number:

-

1U3252RC

-

Condition:

-

new

-

Weight:

-

7, 7kg

-

Max Jaw Opening:

-

45

-

Material:

-

30CrMnSi,

-

Packing:

-

wooden case

-

Hardness:

-

48-53HRC tip part

-

Working condition:

-

Hard Rock, Mine

-

Delivery time:

-

3 days

-

Process:

-

forging

-

Certification:

-

ISO14001:2015, ISO14001:2015

-

Color:

-

Grey

Quick Details

-

Suitable Excavator(ton):

-

1.2ton, 20ton, 4ton, 50ton, 3ton, 20

-

Bucket capacity:

-

4m³

-

Bucket type:

-

Standard bucket

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Guanzhuo

-

Model Number:

-

1U3252RC

-

Condition:

-

new

-

Weight:

-

7, 7kg

-

Max Jaw Opening:

-

45

-

Material:

-

30CrMnSi,

-

Packing:

-

wooden case

-

Hardness:

-

48-53HRC tip part

-

Working condition:

-

Hard Rock, Mine

-

Delivery time:

-

3 days

-

Process:

-

forging

-

Certification:

-

ISO14001:2015, ISO14001:2015

-

Color:

-

Grey

Excavator spare parts J200/J250/J300/J350/J400/J460/J550 bucket teeth

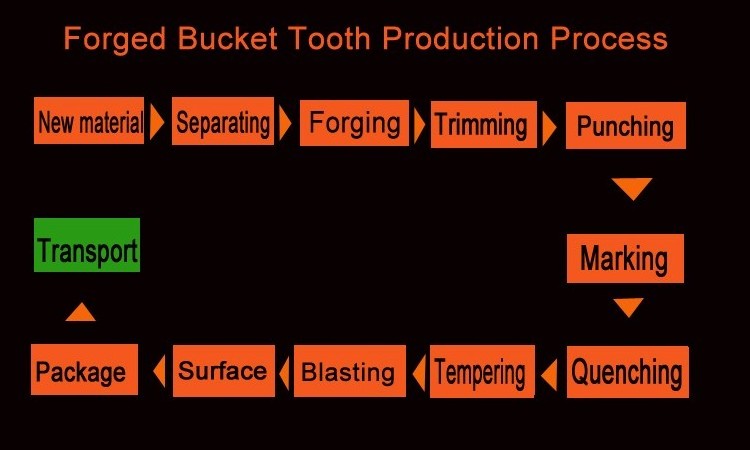

The bucket teeth is forged, not cast. Forging is a production process involving the shaping of metal using localized compressive forces.

Compared with casting, forging parts have more advantages. Due to different producing process, the inner structure of forging parts is more compact. Thus, the working life of forged bucket teeth is much longer and th e strength is higher than casting parts.

Since the Industrial Revolution, forged parts are widely used in machinery industry wherever a component requires high mechanical properties. Kindly refer to following our production process:

v Our Advantages of forged excavator parts

High quality products, circumspect service and Punctual/Prompt delivery time are our top pursuit!

1 . From material selection to production, we have a high-quality technical personnel in the control, which makes GZ bucket tooth obvious different from the competitor.

2. We use high quality wear-resistant materials strategically to improve the wear-resistance/durability and extend the working life of our bucket teeth;

3. The forging technology makes sure the whole quality performance of our products is much better than cast ones;

4. Due to proficient craft process and rich experience, GZ bucket teeth’s impact strengt h is more than 20MJ/M2 and hardness is 50-53HRC at tip part, which make sure our products more durable and longer working hours.

5. Both teeth and adapters can be customized, which ensures good/high fit between bucket teeth and teeth adapters.

6. The high fit between teeth and adapter also brings faster bucket filling and shorter downtime, which is benefit for improving productivity.

7. All of our products are under the control of ISO 9001:2008 strictly

8. OEM and ODM service is offered

Products ’ Presentation of forged excavator parts:

v Application and Brand of forged excavator parts

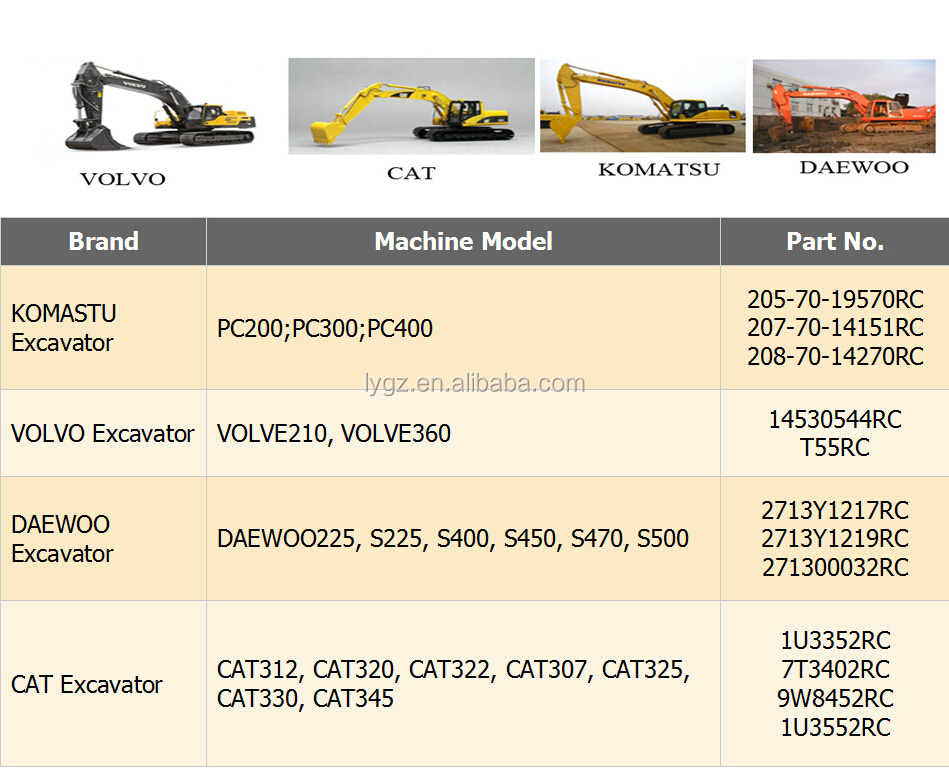

The forg ed bucket teeth are used for a wide range of excavators, for example Komatsu, Daewoo, Caterpillar, Volvo et c.

v Working site of forged excavator parts

v Packaging & Shipment of forged excavator parts

All our bucket teeth are wrapped with poly bag in strong plywood cases with pallet.

We have good contact with famous shipping companies, for example Mearsk, MSC, COSCO, CMA etc.

A full range of sea and air logistics system to provide you with the most convenient logistics experience, rapid response to save your time. The most professional sales and engineers to serve you.

The models we have in stock:

For more information, please feel free to contact us .