- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

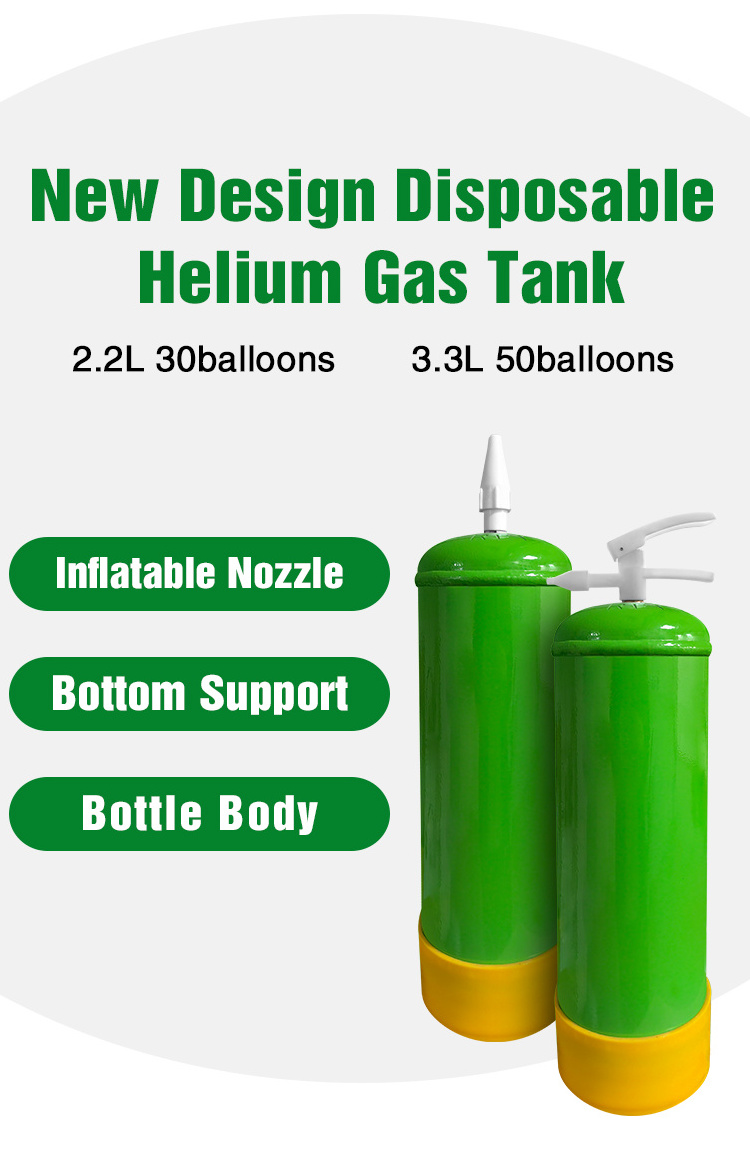

0.95L/2.2L/3.3L

-

Brand Name:

-

SEFIC

-

Water Capacity(L):

-

0.95L/2.2L/3.3L

-

Working Temperature(℃):

-

-20~65

-

Filling Gas:

-

He.Ar.other gas-Foodgrade

-

Working Pressure(bar):

-

110

-

Test Pressure(bar):

-

165

-

Burst pressure(bar):

-

Min.264

-

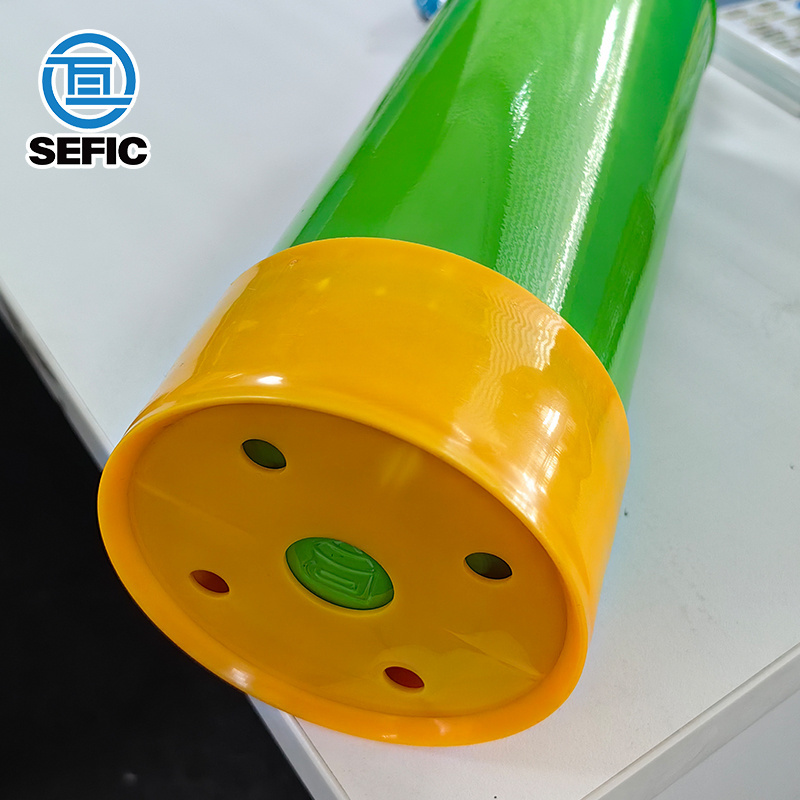

Outside Cylinder Diameter(mm):

-

118±2

-

Bottle height(mm):

-

325±2

-

Weight(kg):

-

2.6

-

Min.design wall thickness(mm):

-

2.8

Quick Details

-

Material:

-

Steel

-

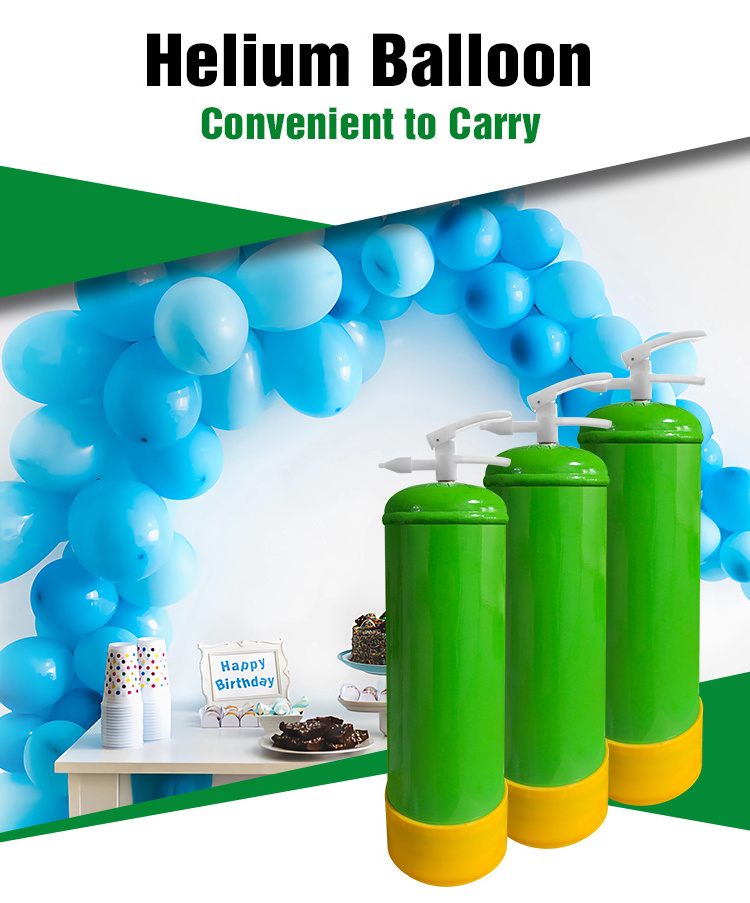

Use:

-

helium cylinder

-

Place of Origin:

-

Shanghai, China

-

Model Number:

-

0.95L/2.2L/3.3L

-

Brand Name:

-

SEFIC

-

Water Capacity(L):

-

0.95L/2.2L/3.3L

-

Working Temperature(℃):

-

-20~65

-

Filling Gas:

-

He.Ar.other gas-Foodgrade

-

Working Pressure(bar):

-

110

-

Test Pressure(bar):

-

165

-

Burst pressure(bar):

-

Min.264

-

Outside Cylinder Diameter(mm):

-

118±2

-

Bottle height(mm):

-

325±2

-

Weight(kg):

-

2.6

-

Min.design wall thickness(mm):

-

2.8

Products Description

1.The cylinder id designed,manufactured,inspeted in accordance with BS EN 12205:2004;

2.The cylinder material is Q235B steel,which meets the chemical composition requirements of clause 5.3.1.2 in BS EN ISO111118:2015

2.1.The chemical compositions should be rechecked according to stove number and have the following limits;

|

Element

|

C max

|

Mn max

|

P max

|

S max

|

|

Eass(%)

|

0.25

|

0.50

|

0.025

|

0.025

|

2.2.Mechanical propenties should meet the following requirements:

|

R ma(Mpa)

|

R ea(MPa)

|

A(%)

|

|

370≤R ma≤500

|

R ea≥325

|

≥16

|

3.The weld between upper and bottom end with cylinder body should adopt mixed gas(Ar+CO2=8:2)arc welding.The welding wire type is ER50-6.The welded construction meets the requirements of item 8.1.1.2 in BS EN 1118:2004;

4.Non-refillable valves shall be attached with non-refillable cylinders permanently;

5.Plasma welding is used for the longitudinal welds of cylinder ical body.

Related Products

Applications

Production Process

Hot Searches