Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 YEAR

-

Brand Name:

-

FUNLE

-

Model Number:

-

DN25

-

Place of Origin:

-

Zhejiang, China

-

Horsepower:

-

Pneumatic

-

Power Source:

-

220/380

-

Structure:

-

Pneumatic PUMP

-

Outlet Size:

-

DN25

-

Power:

-

Pneumatic

-

motor:

-

Pneumatic

-

Material:

-

SS304/SS316L

Quick Details

-

Application:

-

Automotive Industry, Biofuel Industry, Commercial Buildings, Developing World Water Solutions, District Energy, Drinking water treatment, Family Homes, Food and Beverage Industry, HVAC OEM, Industrial Boilers, Industrial Utilities, Irrigation and Agriculture, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry, Raw Water Intake, temperature control, Washing and Cleaning, Wastewater Transport and Flood Control, wastewater treatment, Water Distribution, Water Treatment Solutions, Other

-

Pressure:

-

0.3-0.7MPA

-

Voltage:

-

220/380

-

Warranty:

-

1 YEAR

-

Brand Name:

-

FUNLE

-

Model Number:

-

DN25

-

Place of Origin:

-

Zhejiang, China

-

Horsepower:

-

Pneumatic

-

Power Source:

-

220/380

-

Structure:

-

Pneumatic PUMP

-

Outlet Size:

-

DN25

-

Power:

-

Pneumatic

-

motor:

-

Pneumatic

-

Material:

-

SS304/SS316L

Overview

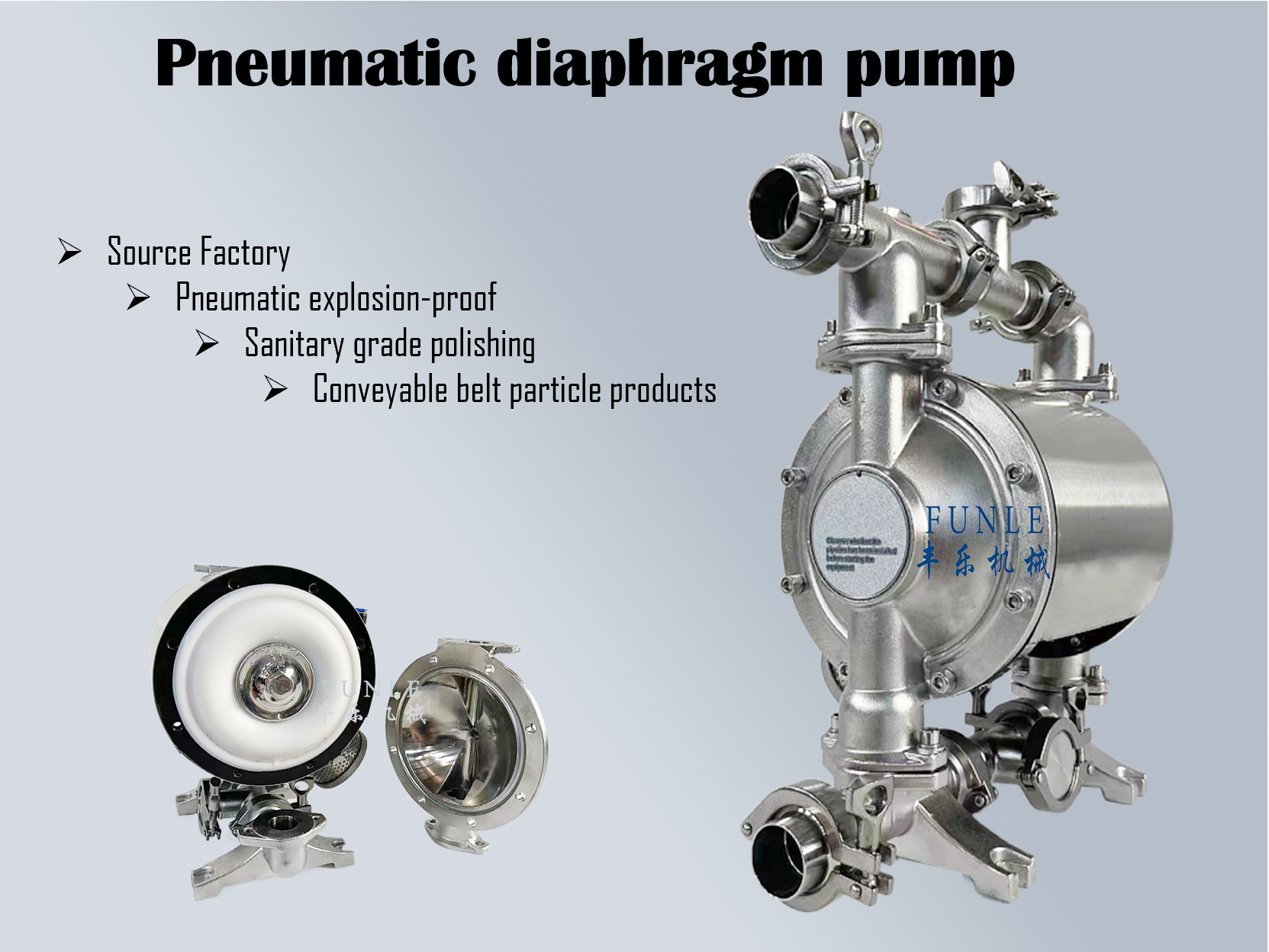

QBSY series pneumatic diaphragm pump produced by our company is a new type of conveying equipment, which is currently the largest one in China The latest pumps. Compressed air is used as the power source. All kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable and highly toxic liquids can be pumped up.

Parameters

Working principle

pneumatic diaphragm pump working principle: in the two symmetrical working chambers of the diaphragm pump, each is equipped with An elastic diaphragm, the connecting rod integrates the two diaphragms, and compressed air enters from the air inlet joint of the pump After the inlet valve chamber, push the diaphragms of the two working chambers to drive the diaphragm connected by the connecting rod to move synchronously. With this At the same time, the gas in the other working chamber is discharged out of the pump from the back of its diaphragm. When the piston reaches the end of stroke The valve mechanism automatically introduces compressed air into another working chamber to push the diaphragm pump to move in the opposite direction, In this way, the synchronous reciprocating motion of the two diaphragms is formed. Two one-way ball valves are set in each working chamber The reciprocating motion of the diaphragm causes the volume of the working chamber to change. With the alternating opening and closing of the two one-way ball valves, the liquid is continuously inhaled and discharged.The most obvious difference between

pneumatic diaphragm pump and other diaphragm pumps is the structure of valve.

pneumatic diaphragm pump air valve structure eliminates the traditional "O" ring and cylindrical valve structure of gas distribution Valve. The three-phase pilot type is adopted to eliminate the valve dead point and pump shutdown. Provides correct and reliable commutation Signal to avoid shutdown and faster commutation, so that the pump has a larger flow, improves the transmission performance, and makes the pulse Smaller impact, more stable flow.

|

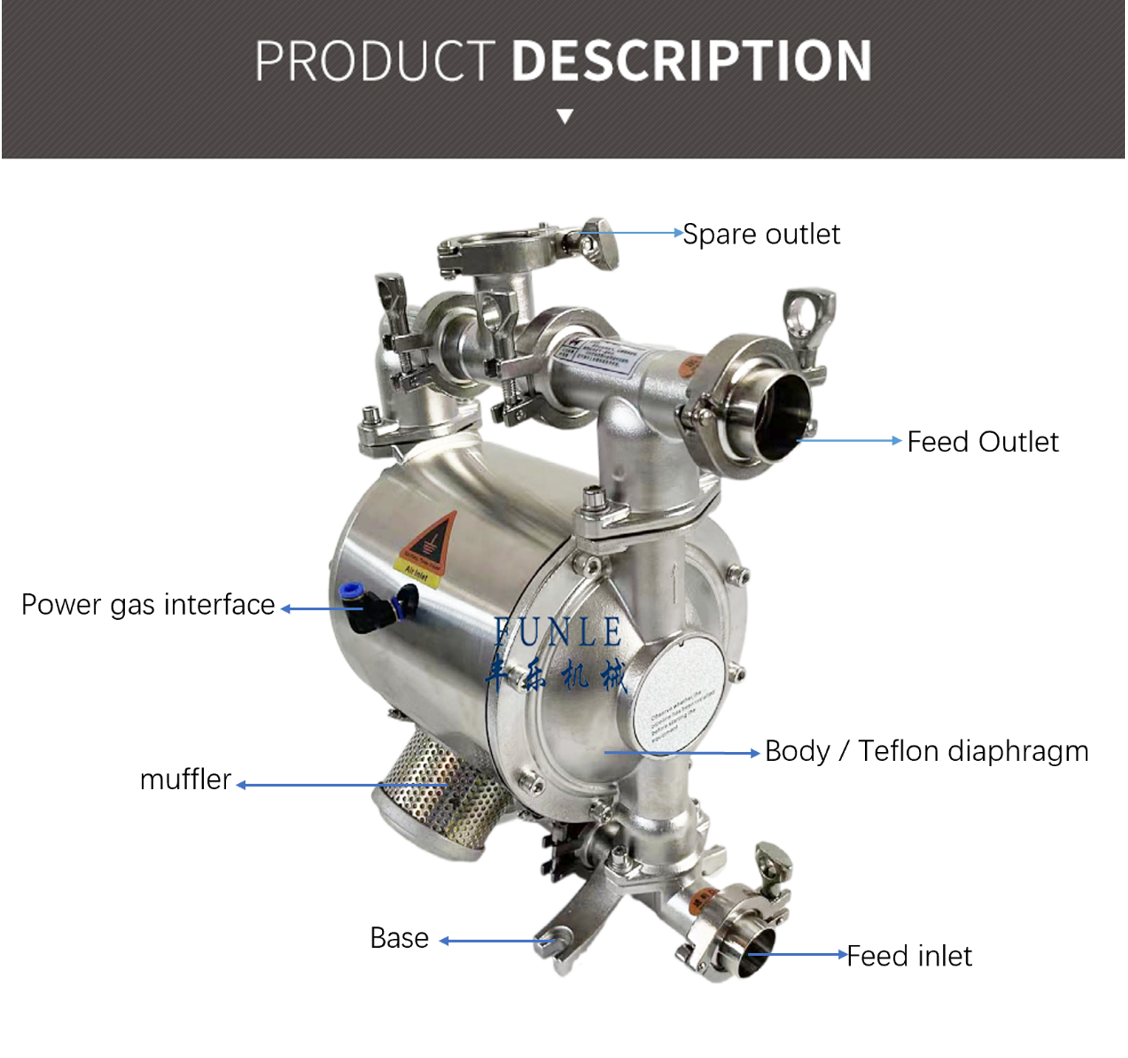

01. Discharge port (upper cover)

|

02. plug

|

03. ball valve

|

04. ball socket

|

|

05. gasket of air valve chamber

|

06. auxiliary lever

|

07. slider

|

08. Piston V-ring

|

|

09. piston

|

10. Guide block

|

11. Gasket of air valve chamber

|

12. Guide block gasket

|

|

13. air valve chamber

|

14. Air valve cover

|

15. Auxiliary lever O-ring

|

16. connecting rod shaft sleeve

|

|

17. Silence

|

18. Air valve chamber seat

|

19. Column

|

20. Splint screw

|

|

21. Outer splint

|

22. Tetrafluoro diaphragm

|

23. Inner splint

|

24.0 ring

|

|

25. Connecting rod shaft V-ring

|

26. connecting rod shaft

|

27. Feed inlet (lower cover)

|

|

1. About Delivery term

Q: What's the delivery term for doing business with you?

A: EXW/FOB/CIF/DDU… it depends on preference of clients.

2. About Lead time

Q: What's the leading time after placing order?

A: After getting your confirmation, mixing tank about 25 days, pump 15 days, colloid mill 10 days. However, it depends on

production schedule is in slack or peak season, and the complication of machines.

3. About Payment time

Q: What's the payment term?

A: T/T 40% as down payment, 60% balance payment before delivery.

4. About Quality

Q: How do you control your quality?

A: All machines before delivery will be tested and send video for customer, if no problem then arrange balance payment.

Meanwhile,CE is available for customers' needs.

5. About Packing

Q: How do you pack the machines?

A: Standard export wooden case, to avoid damage during delivery.

6. About Customized

Q: Can you produce according to the samples?

A: Yes,we can produce by your samples or technical drawings.

Q: What's the delivery term for doing business with you?

A: EXW/FOB/CIF/DDU… it depends on preference of clients.

2. About Lead time

Q: What's the leading time after placing order?

A: After getting your confirmation, mixing tank about 25 days, pump 15 days, colloid mill 10 days. However, it depends on

production schedule is in slack or peak season, and the complication of machines.

3. About Payment time

Q: What's the payment term?

A: T/T 40% as down payment, 60% balance payment before delivery.

4. About Quality

Q: How do you control your quality?

A: All machines before delivery will be tested and send video for customer, if no problem then arrange balance payment.

Meanwhile,CE is available for customers' needs.

5. About Packing

Q: How do you pack the machines?

A: Standard export wooden case, to avoid damage during delivery.

6. About Customized

Q: Can you produce according to the samples?

A: Yes,we can produce by your samples or technical drawings.

Hot Searches