- Product Details

- {{item.text}}

Quick Details

-

MF:

-

(C3H5NO)n

-

EINECS No.:

-

201-173-7

-

Place of Origin:

-

Jiangsu, China

-

Type:

-

Polyacrylamides

-

Brand Name:

-

Bluwat

-

Model Number:

-

Cationic

-

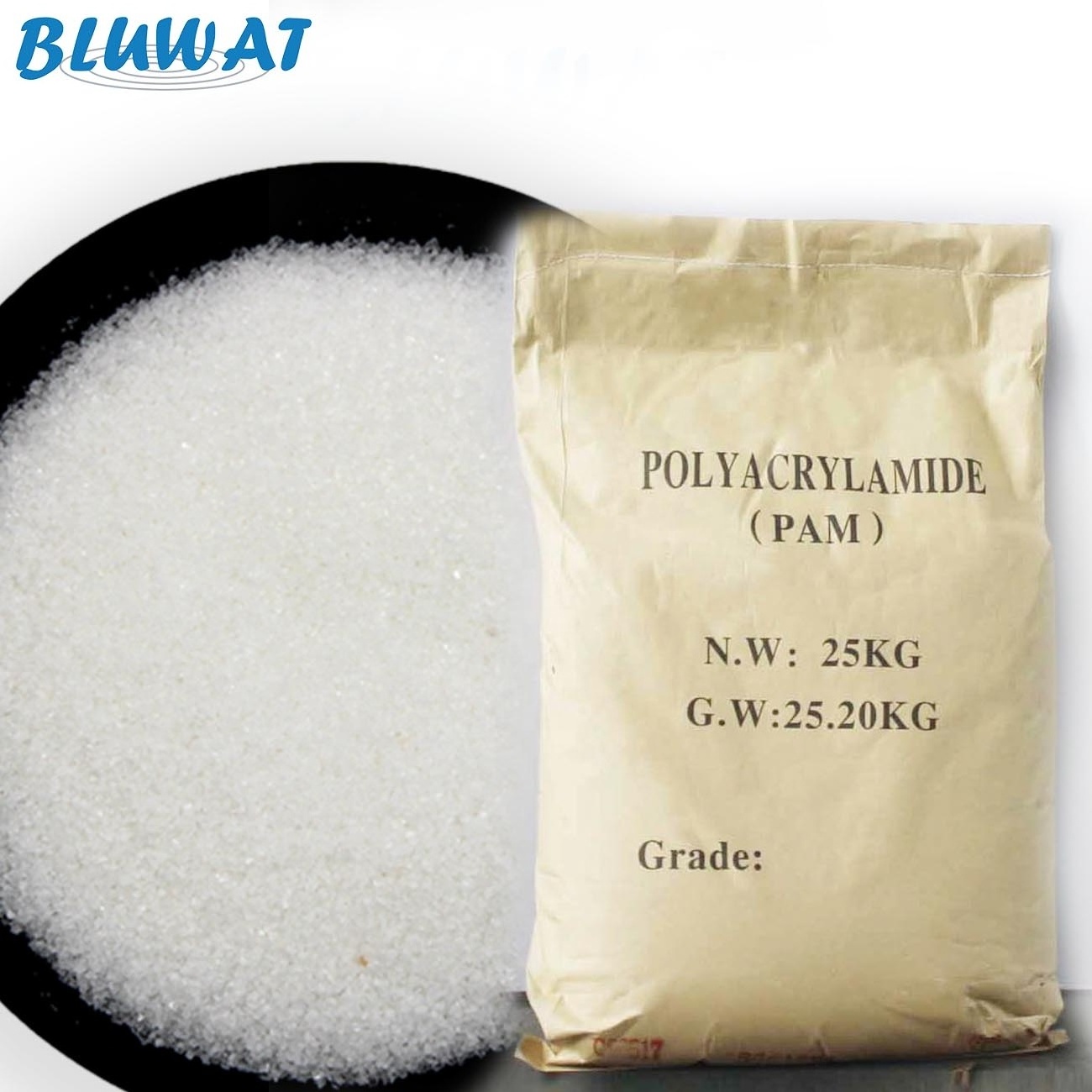

Appearance:

-

White Powder

-

Product name:

-

Drilling polymer

-

application:

-

Drilling mud additives

-

molecular weight:

-

15-20million

-

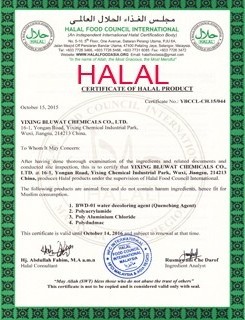

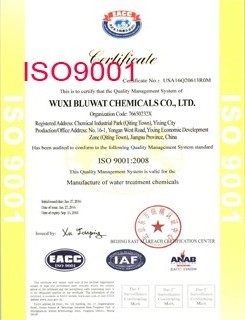

Certificate:

-

ISO9001

-

Package:

-

25kg/bag

-

Sample:

-

Free sample

-

Solid content:

-

>90%

-

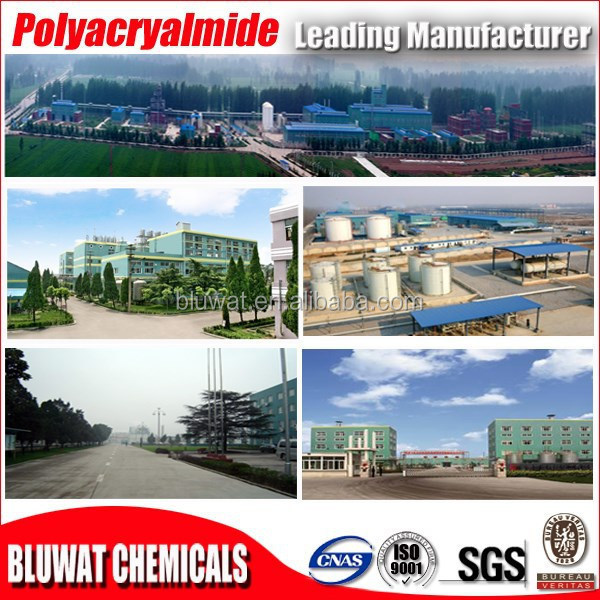

Manufacturer:

-

Yixing Bluwat Chemicals

Quick Details

-

CAS No.:

-

9003-05-8

-

Purity:

-

100%

-

Other Names:

-

PHPA

-

MF:

-

(C3H5NO)n

-

EINECS No.:

-

201-173-7

-

Place of Origin:

-

Jiangsu, China

-

Type:

-

Polyacrylamides

-

Brand Name:

-

Bluwat

-

Model Number:

-

Cationic

-

Appearance:

-

White Powder

-

Product name:

-

Drilling polymer

-

application:

-

Drilling mud additives

-

molecular weight:

-

15-20million

-

Certificate:

-

ISO9001

-

Package:

-

25kg/bag

-

Sample:

-

Free sample

-

Solid content:

-

>90%

-

Manufacturer:

-

Yixing Bluwat Chemicals

|

Congo Drilling Polymer PHPA |

| Blufloc Polyacrylamide: | |

| Trade Name: | PHPA |

| Active Ingredient: | High molecular weight polymer |

| Chemical Name: | Anionic polymer |

| CAS No.: | 9003-05-8 |

| Standard: | GB17514-2008 |

| Brand: | Blufloc |

| Certification: | ISO, SGS |

| MOQ: | 500kgs |

| Port of Loading: | Shanghai Port, China |

| Delivery Time: | Within 10 Working Days After Got Your Payment |

| Package: | Packed in 25kgs kraft bag or white PE bag on pallet and 18-20ton/FCL, or 750kgs big bag |

| Applications: | Drilling, oil & gas, Enhanced oil recovery |

| Sample: | Free to test |

|

Type & Technical index: |

|||

|

Technical index |

HA6518 |

HAA7520 |

HAA8525 |

|

Granularity (mesh) |

20-80 |

||

|

Solid (%) |

≥89 |

||

|

Dissolved time(h) |

≤2 |

||

|

Insoluble matter (%) |

≤0.2 |

||

|

Molecular weight(10X6) |

≥1800 |

≥2000 |

≥2500 |

|

Degree of hydrolysis (%) |

25-40 |

||

|

Residual monomer (%) |

≤0.1 |

||

|

Filtration ratio |

≤2.0 |

||

|

Apparent Viscosity (mpa.s)

|

≥11.5 |

≥12.5 |

≥12.5 |

|

Apparent Viscosity (mpa.s)

|

≥40 |

≥45 |

≥50 |

|

Retention rate of shearing Viscosity (%) |

≥80 |

||

|

Retention rate of static adsorption Viscosity (%) |

≥80 |

||

|

|

|||

|

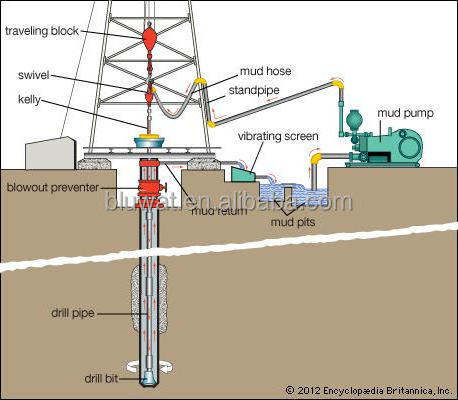

Main Applications: Oil-displacing Agent of Oil Field Tertiary Oil Recovery: It can adjust the rheology of filled water, increase the viscosity of driving liquid, improve water drive wave and efficiency, lower water phase permeability in ground layer, and enable water and oil to flow forward at even speed. Its effect is that it is mainly used in tertiary oil recovery of oil fields in the aspect oil production, and raw oil of about 100 to 150ton more can be produced through filling the macromolecule polyacrylamide product one ton.

Well Drilling Mud Raw Materials: In oil field exploration and development and exploration of geology, water and coal, it is used as adhesive of well drilling mud raw materials, can improve the service life of drill bits, improve the drill speed and drilling footage, and reduce plug in replacing drill, and has prominent well slough preventing effect, and it can be used as fracturing fluid of oil fields or plugging agent of controlling profile and plugging water.

Flocculant: The polarity gene adsorbs the solid particles dispersed in water, bridges between the particles and formats the large aggregates, sedimentation and separates of water, flocculates detritus and clay in drilling fluid.

Dispersant: In the drilling mud treatment, this product can improve the lubricity and stability of the mud to reduce the water loss, prevent sticking effectively, increase drilling efficiency.

Blocking Agent:

Lubricant:

Fluid Loss Additive: The hydrolysis degree is higher, the hydration group on the molecular chain is more, the hydration is better, and it changes from flocculant into fluid loss additive. Drilling mud should be treated to keep cake’s permeability as low as possible in order to maintain a stable borehole and to minimize filtrate invasion, and damage to the pay zone.

Shale Inhibition Agent: The multipoint adsorption of polymer formats to the crisscross membrane macromolecules, plays a role of enhancing the stability of borehole . |

| How To Use The Blufloc Polyacrylamide? |

|

Application and Dosage:

The dosage range of varies from 0.2 - 3.0 ppm depending upon the type of effluent and application. Advised to do jar tests for evaluating the functioning and approximate dosage.

Put sample of effluent in a beaker and add it as designated, agitate for 1 minute at 100-120 rpm and then slowly agitate at 60rpm. Determine the floc properly at this time and note the sedimentation and clarity of top solution.

|

|

Contact us for more information:

|

|

Package and Storage:

|

|

Main Products: |

|