Description:

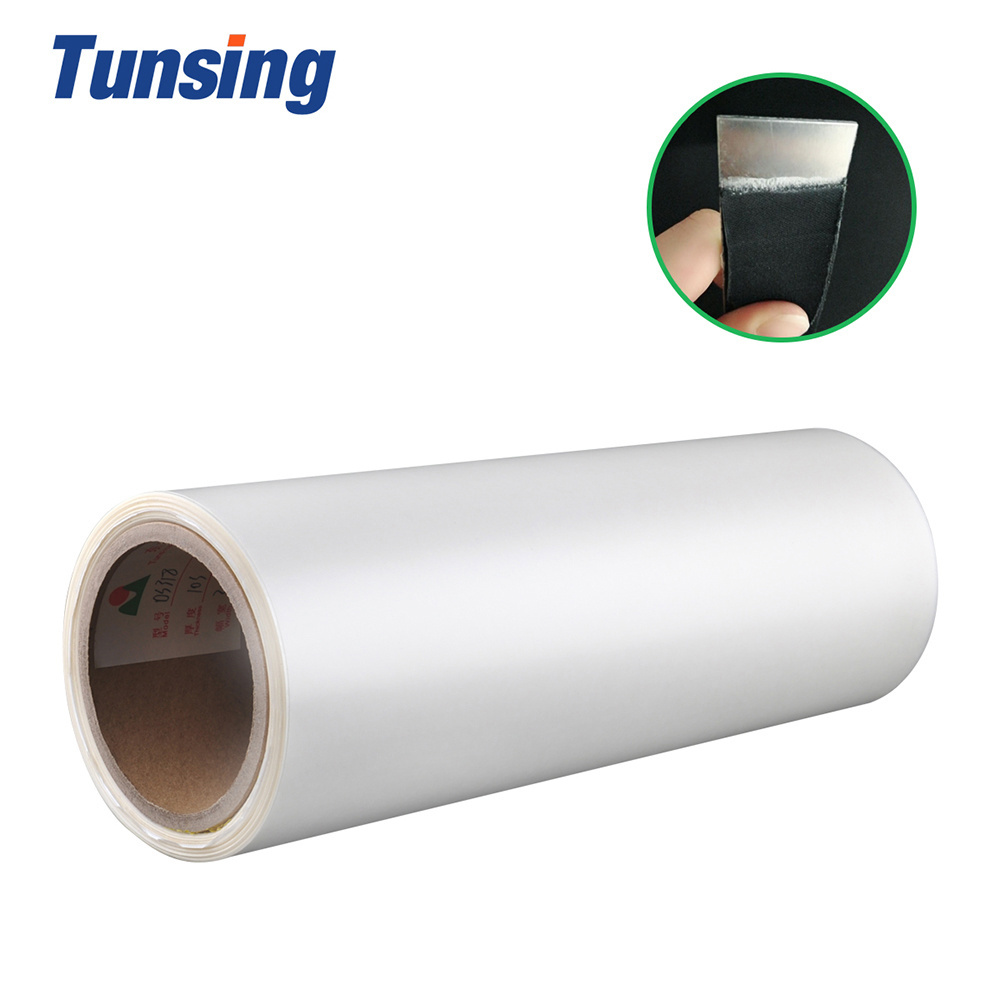

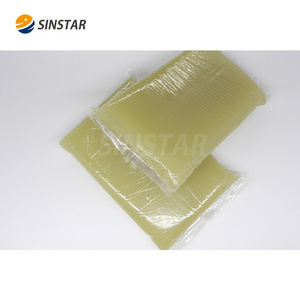

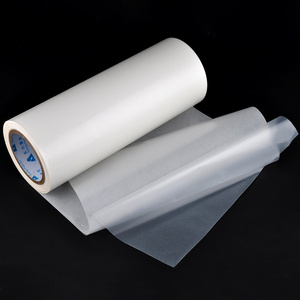

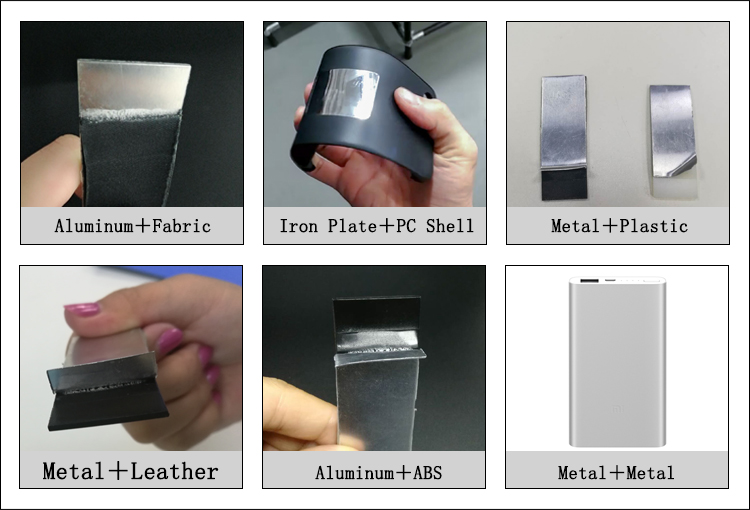

This product is a thermoplastic adhesive, It can be heated repeatedly and bonded. It performs an excellent adhesion for Metal (stainless steel, copper, iron, aluminum, etc), Plastic (PET, ABS, PC, etc.)This adhesive exhibit excellent heat resistance, cold resistance and water resistance.

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

..

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Tunsing

-

Model Number:

-

DS8303

-

Type:

-

Hot melt adhesive

-

Color:

-

Amber

-

melting point(°C):

-

80℃

-

Melt Flow Index:

-

27±7g/10min Condition:ASTMD1238-04

-

operating Temperature:

-

110℃-140℃

-

Density:

-

1.0±0.02g/cm3

-

certifications:

-

ISO9001

-

Conventional thickness:

-

0.05mm,0.08mm

-

Conventional Width:

-

1380mm

-

Finished Products Specification:

-

1380mm*100yards/roll

Quick Details

-

CAS No.:

-

.

-

Other Names:

-

.

-

MF:

-

.

-

EINECS No.:

-

..

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Tunsing

-

Model Number:

-

DS8303

-

Type:

-

Hot melt adhesive

-

Color:

-

Amber

-

melting point(°C):

-

80℃

-

Melt Flow Index:

-

27±7g/10min Condition:ASTMD1238-04

-

operating Temperature:

-

110℃-140℃

-

Density:

-

1.0±0.02g/cm3

-

certifications:

-

ISO9001

-

Conventional thickness:

-

0.05mm,0.08mm

-

Conventional Width:

-

1380mm

-

Finished Products Specification:

-

1380mm*100yards/roll

Product:

DS8303

Application

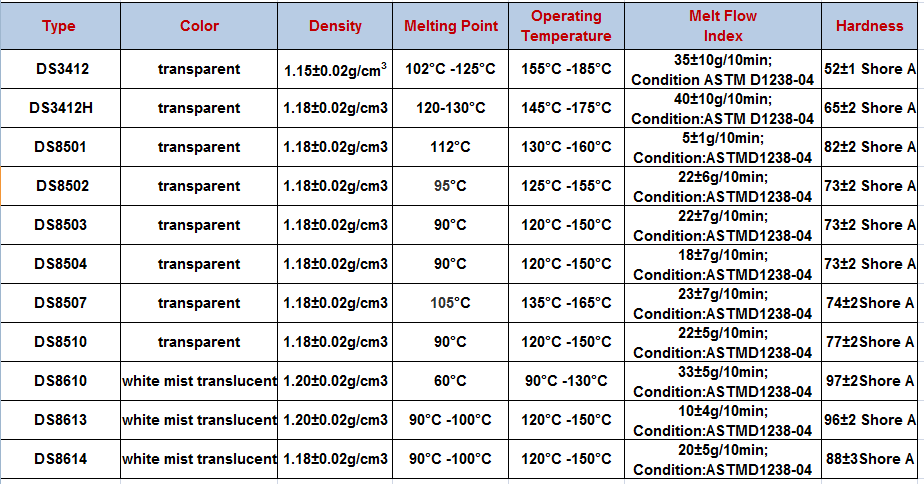

Physical Characteristics:

Color :

Amber

Density :

1.0±0.02g/cm³

Melt Flow Index :

27±7g/10min (Condition:ASTMD1238-04 )

Operating Temperature :

110℃-140℃

Flow Beginning Point :

80℃

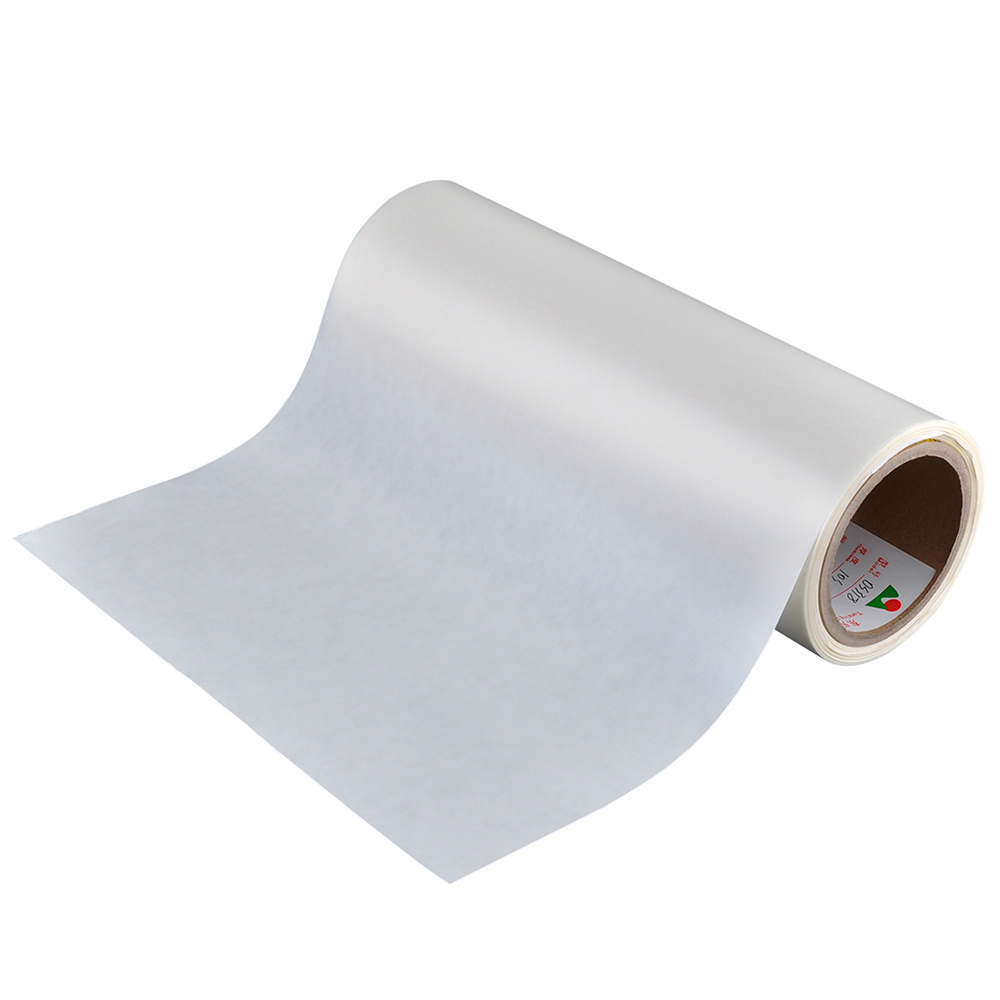

Release Liner :

Glassine release paper

Conventional thickness :

0.08mm, 0.10mm

Conventional Width :

1380mm

Length :

100 yards

Finished Products Specification :

1380mm*100yards/roll

Recommended Bonding Conditions:

|

Flat Press

|

Second Flat Press

|

|

Machine Setting: 100℃-120℃

|

Machine Setting: 110℃-140℃

|

|

Dwell Time: 5-10 seconds

|

Dwell Time: 8-25seconds

|

|

Pressure: 0.3-0.6mpa

|

Pressure: 0.3-0.6mpa

|

1, Bonding temperature and pressure as well as the time involved in the strength of the film to material. Bonding temperature must be close to the machine set the temperature, the pressure must be uniform, mold and pressure roller must be flat.

2, In different machinery and materials, the bonding conditions used will be different. The conditions marked here are only basic. The optimum bonding conditions should be made by creating suitable construction conditions for the particular application damage, direct or consequential, arising out of the use, misuse or inability to use the product.Why Us:

1, more than 10 years experience in production.

2, well-known products: Sichuan Famous Brand.

3, Good quality control in production process: Quality Service AAA Grade Credit Enterprise

4, Excellent quality and Competitive price, OEM is available.

5, Stable supply: an extensive range of stock.

6, The whole process from material to end products is under supervision.

Our Service:

1, Your inquiry will be replied within 24 hours and online service is available all the time.

2, Well-trained & professional sales persons are here ready to answer all your questions and handle the problems.

3, Prompt delivery time: within 15 days after agreement

4, Flexible payment terms: T/T, L/C, O/A, Western Union, Paypal, Escrow, etc.

5, Your business relationship with us will be confidential to any third party.

6, Good after-sale service offered, please get back if you got question.

1, Q: How will you pack the product?

A: We pack with paper cartons, usually 4 or 6 rolls per carton for hand stretch film; 1 roll for machine stretch film; 56 or 84 rolls for mini stretch film and 27 rolls per pallet for jumbo stretch film.

2, Q: How many rolls can be full fitted into one container, such as 20FT, 40FT?

A: The details are in the above forms. If your specification is different, you need to tell us the size of the carton, and then we will calculate for you accordingly.

3, Q: How about the adhesive of the stretch film?

A: It is self adhesive stretch film. We can produce one side and two sides adhesive but usually one side adhesive. Besides, the stickiness can be controlled as customized.

4, Q: How many layers of the stretch film can your equipment make?

A: Our equipment can produce 1/2/3 layers stretch film.

5, Q: Do you accept OEM?

A: Yes, we do.

6, Q: Do you provide free sample? And how many days it will take?

A: Yes, we provide free sample, only need you to pay the courier charge. We will make the sample within 3 working days and it will take 3-7days on the transportation.

7, Q: What's your delivery time?

A: We are factory, so we can efficiently control the production time, and then for the delivery time, it is 5-20 working days.

8, Q: What's your production capacity?

A: At present, our production capacity is 100 metric tons per month. However, we are planning to open a new factory and add more production lines.

9, Q: Can you produce colored stretch film?

A: Except clear and transparent, we can make colored stretch film, such as black, white, blue, etc. But mostly we make clear and transparent. If the quantity is big, we will make color stretch film for you.

10, Q: What's your payment term?

A: We accept T/T, L/C, O/A, Western Union, Paypal, Escrow, or customized if it is acceptable.

Contact Me

TEL & Whatsapp &Wechat: 86 181 2626 6193