- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Tengtong or OEM

-

Dimension(L*W*H):

-

6000*492*1800 mm

-

Weight:

-

1200 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support

-

Product name:

-

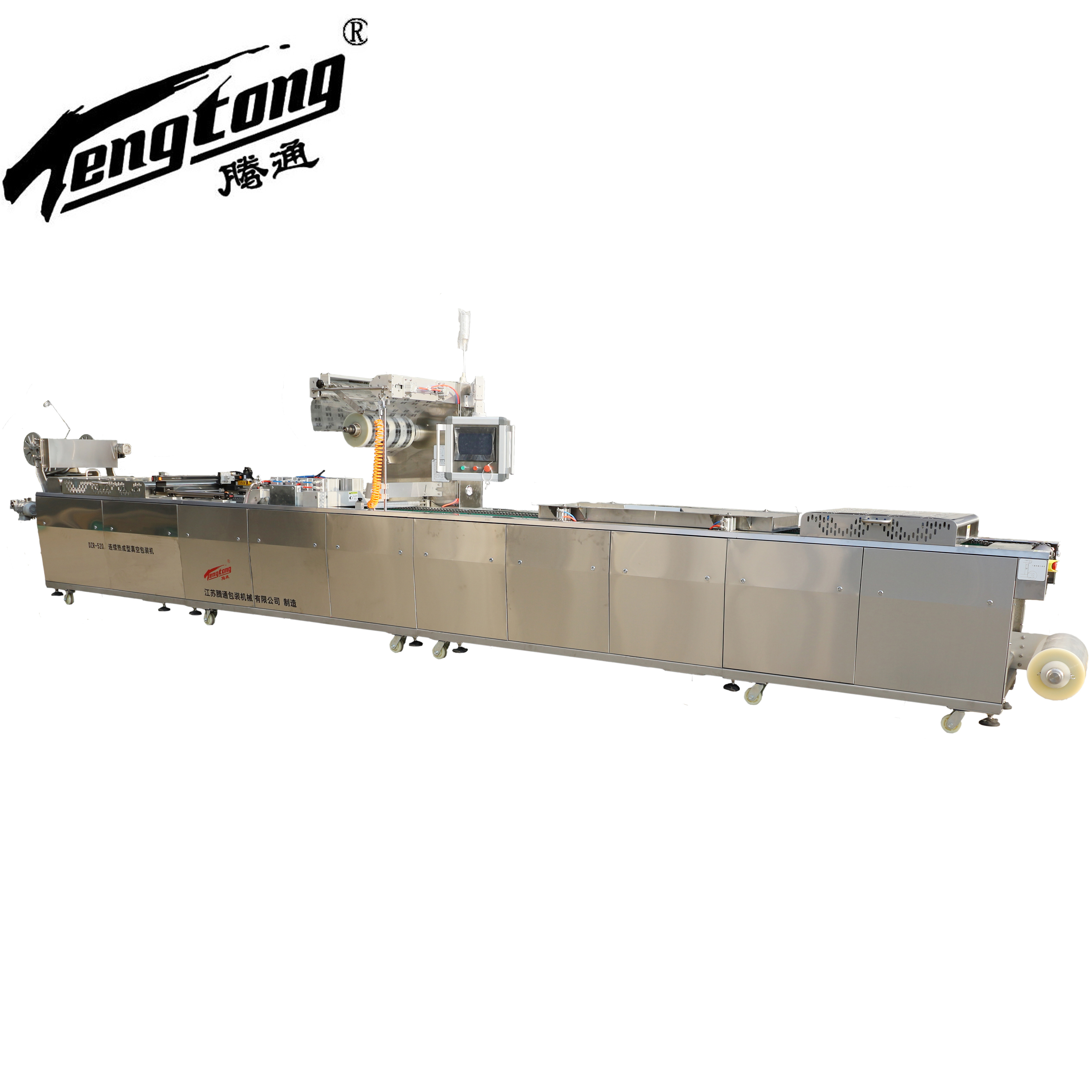

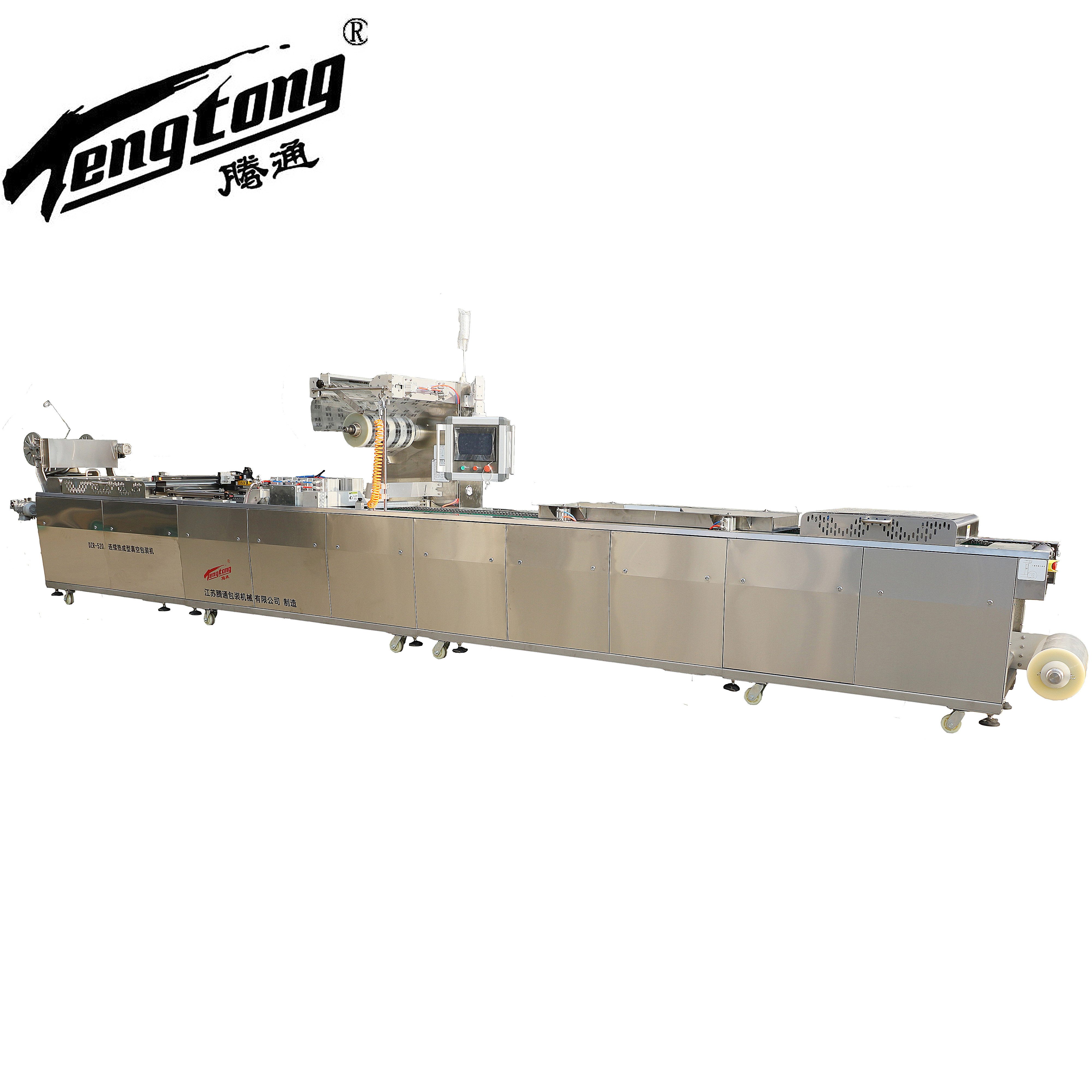

pita bread bakery gas flushing thermoforming vacuum packing machine

-

Material:

-

304 Stainless Steel

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

None

-

Marketing Type:

-

Ordinary Product

-

Certification:

-

CE

Quick Details

-

Packaging Type:

-

Bags, Film, Foil

-

Packaging Material:

-

Plastic

-

Voltage:

-

AC220V or AC380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Tengtong or OEM

-

Dimension(L*W*H):

-

6000*492*1800 mm

-

Weight:

-

1200 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support

-

Product name:

-

pita bread bakery gas flushing thermoforming vacuum packing machine

-

Material:

-

304 Stainless Steel

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

None

-

Marketing Type:

-

Ordinary Product

-

Certification:

-

CE

Products Description

Tengtong

pizza vacuum packing machine

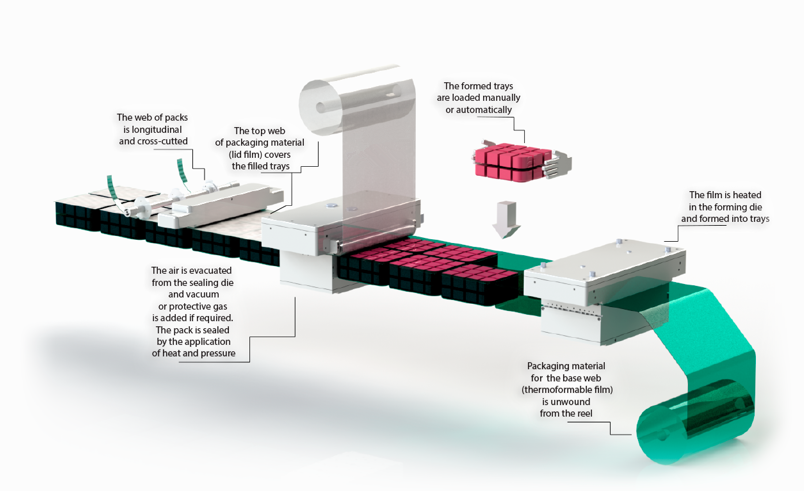

is mainly formed by heating and stretching the bottom film, then vacuuming or inflating the package, and heat sealing the top and bottom film to form a packaging bag, and then cross cut the bag.

The operation is simple, the manpower is greatly reduced, and different types of machines are selected according to the size of the package. The standard frame sizes are 290 mm, 390 mm and 490 mm.

The machine can realize automatic packing from raw materials to finished products through a series of machines such as humanized design matching conveyor line to realize industrial automation.

Features of pizza vacuum packing machine :

1. Wide range of packaging, suitable for a variety of snack foods, medicine, cold meat, eggs and industrial products.

2. Convenient operation: PLC touch screen control, man-machine interface operating system, intuitive and convenient operation.

3. Convenient adjustment: the modification of relevant parameters can be conveniently carried out in the touch screen.

4. Applicable to different types, sizes and sizes of product packaging, one machine multi-mode.

5. Perfect prevention system: such as power supply wrong phase, over voltage, under voltage alarm, forming and sealing temperature abnormal alarm, cutter guard movement alarm, motor protection alarm, power failure protection during equipment operation.

6. The equipment meets the hygienic standard of food processing machinery. The contact between the equipment and the material is processed by 304 stainless steel or other materials that meet the food hygiene requirements to ensure the hygiene and safety of the food and meet the GMP standards.

7. High degree of automation: PLC, touch screen, servo system, reliable operation, accurate action, accurate positioning, automatic alarm when fault occurs.

8. The outer cover of the device is made of 304 brushed stainless steel plate, which has a neat appearance and is easy to clean.

9. Adopt German BUSCH vacuum pump, high vacuum and durable.

10. The whole machine frame adopts industrial aluminum profiles and the surface is electrostatically sprayed to improve the service life of the machine.

Product Paramenters

Main specifications of automatic date thermoforming vacuum packaging machine:

|

Model No.

|

DZR-320

|

DZR-420

|

DZR-520

|

|

Mould working area

|

290*290

|

390*390

|

490*490

|

|

Max thermoforming depth (mm)

|

80

|

80

|

80

|

|

Working efficiency

|

3-4 cycles/MIN

|

3-4 cycles/MIN

|

3-4 cycles/MIN

|

|

Main material

|

SUS304/2B, Aluminum

|

SUS304/2B, Aluminum

|

SUS304/2B, Aluminum

|

|

Vacum pump

|

Busch 0100

|

Busch 0100/160/250

|

Busch 0100/160/250

|

|

Step control system

|

Mitsubishi

|

Mitsubishi

|

Mitsubishi

|

|

PLC

|

Mitsubishi

|

Mitsubishi

|

Mitsubishi

|

|

Main electrical components

|

Schneider , Mitsubishi

|

Schneider , Mitsubishi

|

Schneider , Mitsubishi

|

|

Main pneumatic components

|

Festo

|

Festo

|

Festo

|

|

Total power (kw)

|

10 to 20

|

10 to 20

|

10 to 20

|

|

Voltage

|

AC380V/50HZ/3P(optional)

|

AC380V/50HZ/3P(optional)

|

AC380V/50HZ/3P(optional)

|

|

Overall dimension (mm)( L * W *H)

|

6000*492*1800 mm

|

6500* 900* 1800 mm

|

8300* 900* 1800 mm

|

Details Images

Soft film packing

bottom film is soft film, vacuum packing, gas flush is available.

Rigid film packing

Bottom film is rigid, with vacuum and gas flush packing.

Knife and blade cutiing

this is suitable for soft film cutting.horizontal cut first then vertical cut.

Mould cutting

Especially for rigid tray cutting, can cut the tray without any sharp corners or edges. but this device can't cut the whole mould one time. for example, if one mould has 8 trays, it cut 4 trays first, then move to cut another 4 trays

Laser cutting

for rigid tray cutting, better than mould cutting, use Japan knife, can cutt the whloe mold one time. cutting effect is good.

Why Choose Us

1.Professional team:marketing,designing,engineering

after-sales service.

we are National Standard Drafting Committee of vacuum packaging machine.

pls click youtube link to watch our company introduction video.

https://youtu.be/0KjmpWhCr4M

2. We are partner of Germany BUSCH vacuum pump. We have a lot of BUSCH vacuum pumps in stock, RA040,063,100,202,302 and etc.

pls click youtube link to watch video of BUSCH VACUUM PUMP in stock.

http://www.youtube.com/watch?v=Hu432tJxvAs

Related products

Certifications

CE certificate for vacuum packing machine

CE certificate for vacuum pump

Contact us

Hot Searches