Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Supplier Type:

-

Customized

-

Layers:

-

1-58 layers

-

Certificate:

-

ISO TS16949

-

Surface treatment:

-

HASL, HASL LF, etc.

-

Solder mask:

-

Double -sided green LPI/ customized

-

File needed:

-

Gerber.BOM LIST

-

Material:

-

FR-4 / High TG FR-4 / Halogen Free.etc

-

Service:

-

Offer PCBA design

-

MOQ:

-

1 PCS

-

Layer:

-

1-58 Layers

-

Color:

-

BLACK/ WHITE/GREEN

Quick Details

-

Model Number:

-

PCBA-20

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XZH

-

Supplier Type:

-

Customized

-

Layers:

-

1-58 layers

-

Certificate:

-

ISO TS16949

-

Surface treatment:

-

HASL, HASL LF, etc.

-

Solder mask:

-

Double -sided green LPI/ customized

-

File needed:

-

Gerber.BOM LIST

-

Material:

-

FR-4 / High TG FR-4 / Halogen Free.etc

-

Service:

-

Offer PCBA design

-

MOQ:

-

1 PCS

-

Layer:

-

1-58 Layers

-

Color:

-

BLACK/ WHITE/GREEN

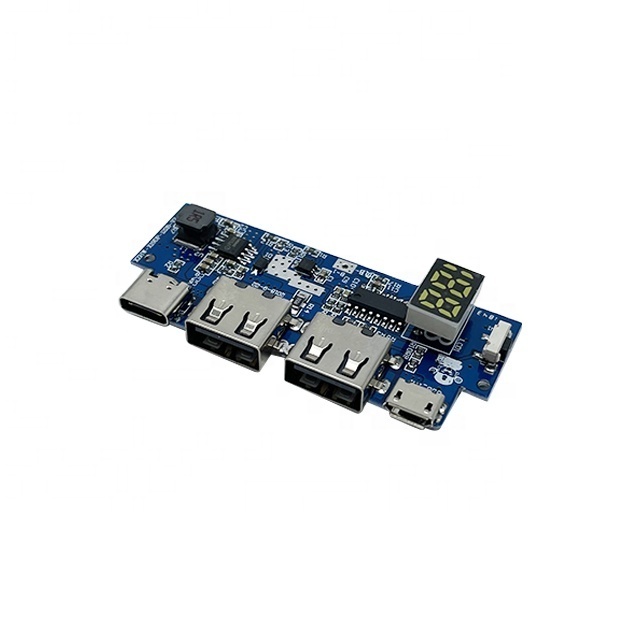

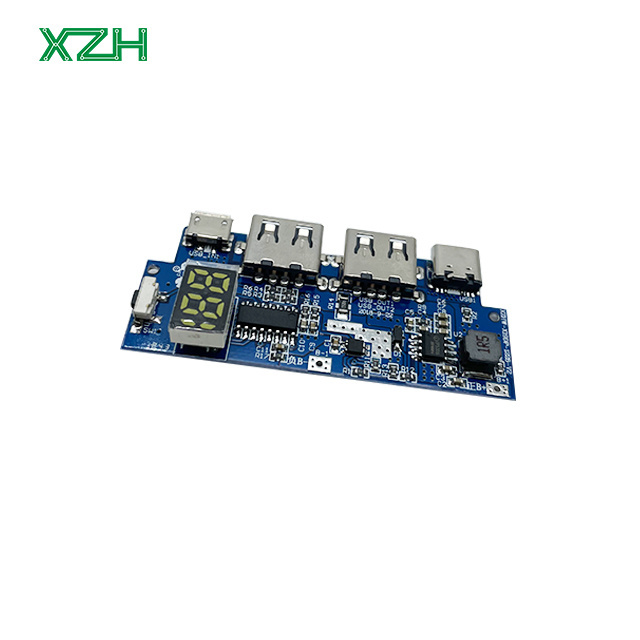

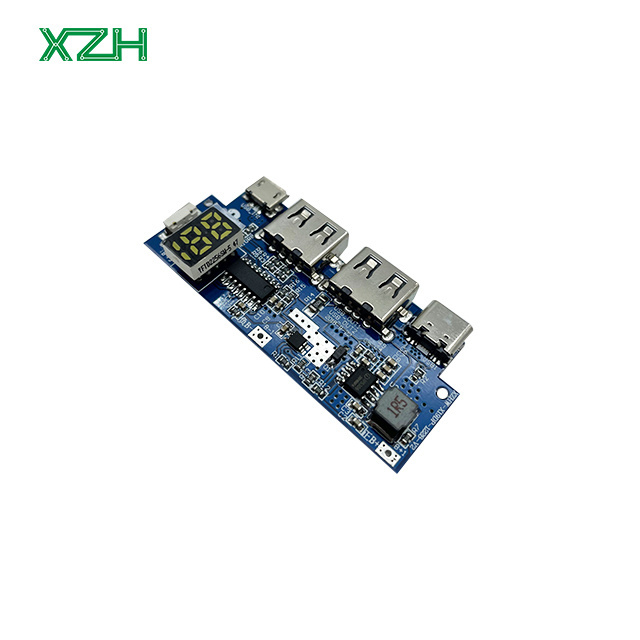

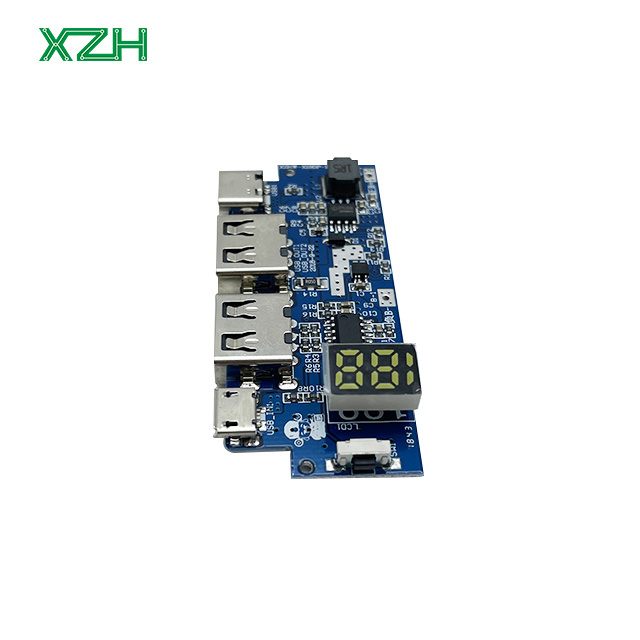

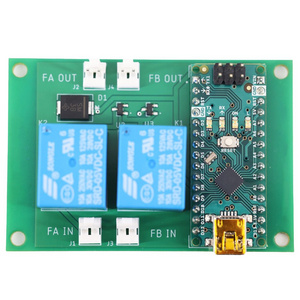

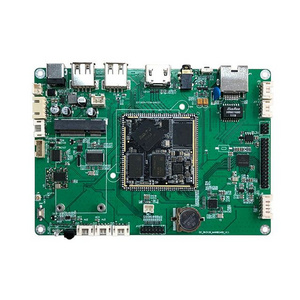

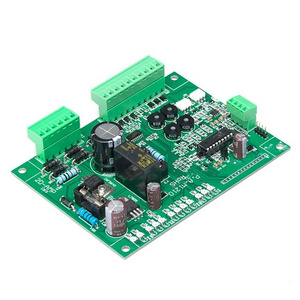

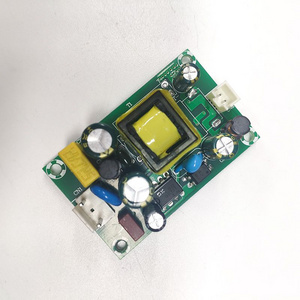

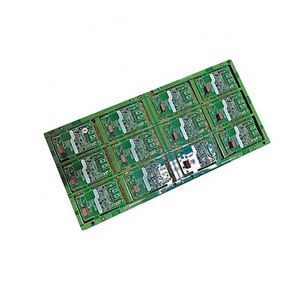

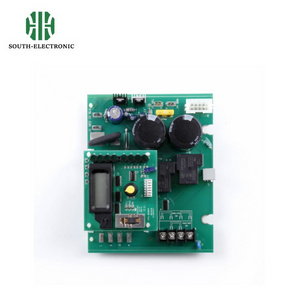

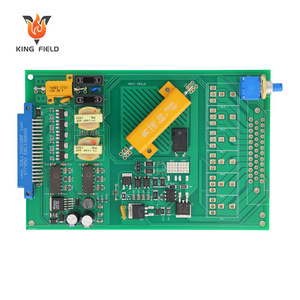

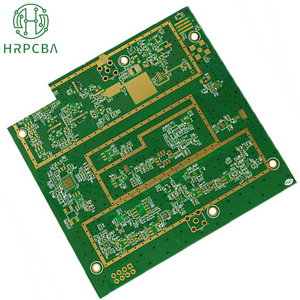

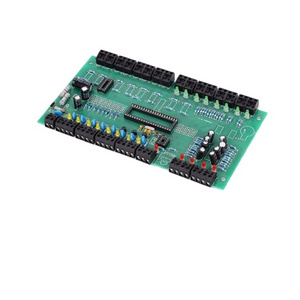

Oem Customized Power Bank Board Pcb Pcba

XZH: Your One-Stop ODM/OEM Solution Provider

Product Introduction

|

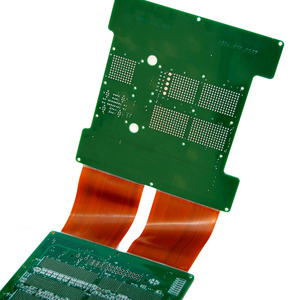

Layers

|

1-58 layers

|

|

Board material

|

FR-4 / High TG FR-4 / Halogen Free material/Rogers/Arlon/Taconic/Teflon

|

|

Surface treatment

|

HASL, HASL lead free, Immersion Gold, Immersion Tin, r, Hard gold, Flash gold, OSP…

|

|

Silk screen colour

|

White / Black / Yellow

|

|

Solder mask colour

|

Green / Blue / Red / Black / Yellow / White

|

Production Capabiity

|

Item

|

Capability

|

|

Base Material

|

FE-4/High TG FR-4/Lead Free Materials (ROHS Compliant)/Halogen Free Material/CEM-3/

CEM-1/PTFE/GOGERS/ARLON/TACONIC

|

|

Layers

|

1-28

|

|

Finised Inner/

Outter Copper Thickness

|

1-6OZ

|

|

Finised Board Thickness

|

0.2-7.0mm

|

|

|

Tolerance: Board Thickness ≤1.0mm: +/-0.1mm

1<Board Thickness≤2.0mm: +/-10%

Board Thickness>2.0mm: +/-8%

|

|

Max Panel SIze

|

≤2 sides PCB: 600*1500mm; Multilayer PCB:500*1200mm

|

|

Min Cinductor Line Wideth/Spacing

|

Inner Layers: ≥ 3/3mil

Outer Layers: 3.5/3.5mil

|

|

Min Hole Size

|

Mechanical Hold: 0.15mm; Laser Hole: 0.1mm; Drilling Precision: First drikking: 1mil, Second drilling: 4mil

|

|

Warpage

|

Board Thickness ≤0.79mm: β≤1.0%

0.80≤Board Thickness≤2.4mm: β≤0.7%

Board Thickness ≤2.5mm: β≤0.5%

|

|

Controlled Impedance

|

+/-5%

|

|

Aspect Ratio

|

15:01

|

|

Min Welding Ring

|

4mil

|

|

Min Solder Mask Bridge

|

≥0.08

|

|

Plugging Vias Capbility

|

0.2-0.8mm

|

|

Hole Tolerance

|

PTH: +/-3mil; NPTH: +/-2mil

|

|

Outline Profile

|

Rout/V-cut/Bridge/Stamp Hole

|

|

Surface Treatment

|

OSP:0.5-0.5um HASL:2-40um

Lead free Hasl:2-40um ENIG:Au 1-10U"

ENEPIG:PB 2-5U""/Au 1-8U'' Immersion Tin:0.8-1.2um

Immersion silver:0.1-1.2um Peelable Blue Mask

Carbon Ink Gold plating:Au 1-150U'

|

|

E-testing Pass Percent

|

97% Pass For The First Time,+/-2%(tolerance)

FQC-Physical Lab:Reliability Tests

|

|

Certificate

|

ROHS, ISO9001:2015, IS013484:2016, IPC3 Staandard

|

For PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) logo customization, the logo can be applied to the following areas:

1. PCB Surface: Logos can be printed on the surface of the PCB, typically in an edge area or a designated non-functional zone.

2. PCBA Assembled Components: If there are visible plastic or other non-conductive material parts on the PCBA, logos can also be printed on these components.

3. Packaging Materials: The exterior or interior packaging for PCBs or PCBAs can feature logos, including packaging boxes, plastic bags, or anti-static bags.

The methods for imprinting logos generally include:

1. Screen Printing: Suitable for PCB surfaces and packaging materials, allowing for single or multi-color logo imprints.

2. Inkjet Printing: Enables high-resolution color printing on PCBs or packaging materials.

3. Laser Marking: Ideal for creating permanent logos on non-conductive parts of PCBs or on metal surfaces.

4. Hot Stamping: Adds a tactile finish to packaging materials with logo imprints.

5. Labeling: Applying labels or stickers with logos onto the PCB or PCBA.

1. PCB Surface: Logos can be printed on the surface of the PCB, typically in an edge area or a designated non-functional zone.

2. PCBA Assembled Components: If there are visible plastic or other non-conductive material parts on the PCBA, logos can also be printed on these components.

3. Packaging Materials: The exterior or interior packaging for PCBs or PCBAs can feature logos, including packaging boxes, plastic bags, or anti-static bags.

The methods for imprinting logos generally include:

1. Screen Printing: Suitable for PCB surfaces and packaging materials, allowing for single or multi-color logo imprints.

2. Inkjet Printing: Enables high-resolution color printing on PCBs or packaging materials.

3. Laser Marking: Ideal for creating permanent logos on non-conductive parts of PCBs or on metal surfaces.

4. Hot Stamping: Adds a tactile finish to packaging materials with logo imprints.

5. Labeling: Applying labels or stickers with logos onto the PCB or PCBA.

Custom packaging options may include:

1. Standard Packaging: Using standard anti-static bags or plastic bags with custom labels on the exterior.

2. Custom Packaging Boxes: Designing and manufacturing packaging boxes with logos based on customer requirements.

3. Eco-friendly Packaging: Packaging made from recyclable or biodegradable materials to reflect environmental sustainability.

4. Shockproof Packaging: Custom shockproof packaging for fragile PCBs or PCBAs that require additional protection.

5. Gift Box Packaging: Custom gift box packaging designed for high-end products or special occasions.

In addition to our comprehensive customization services, we also offer collaborative procurement assistance for a wide range of products. Our goal is to streamline your process and save you valuable time.

Click the CHAT NOW button below to contact our salespeople.

1. Standard Packaging: Using standard anti-static bags or plastic bags with custom labels on the exterior.

2. Custom Packaging Boxes: Designing and manufacturing packaging boxes with logos based on customer requirements.

3. Eco-friendly Packaging: Packaging made from recyclable or biodegradable materials to reflect environmental sustainability.

4. Shockproof Packaging: Custom shockproof packaging for fragile PCBs or PCBAs that require additional protection.

5. Gift Box Packaging: Custom gift box packaging designed for high-end products or special occasions.

In addition to our comprehensive customization services, we also offer collaborative procurement assistance for a wide range of products. Our goal is to streamline your process and save you valuable time.

Click the CHAT NOW button below to contact our salespeople.

Hot Searches