- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

1234*4321*2345

-

Power (kW):

-

65

-

Weight:

-

200

-

Screw Speed (rpm):

-

500 - 800 rpm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Plastic polymer granulating extruder

-

Gearbox reduce ratio:

-

2.5:1 or 3:1

-

Heater:

-

Copper or aluminum heater

-

lead time:

-

40 working days

-

Temperature controller:

-

Omron, RKC, etc

-

self-cleaning:

-

perfect

-

Degree of automation:

-

semi-automatic

-

Screw rotation speed:

-

600Max

-

Color:

-

Customize

Quick Details

-

Output (kg/h):

-

200 - 500 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kerke

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

1234*4321*2345

-

Power (kW):

-

65

-

Weight:

-

200

-

Screw Speed (rpm):

-

500 - 800 rpm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Plastic polymer granulating extruder

-

Gearbox reduce ratio:

-

2.5:1 or 3:1

-

Heater:

-

Copper or aluminum heater

-

lead time:

-

40 working days

-

Temperature controller:

-

Omron, RKC, etc

-

self-cleaning:

-

perfect

-

Degree of automation:

-

semi-automatic

-

Screw rotation speed:

-

600Max

-

Color:

-

Customize

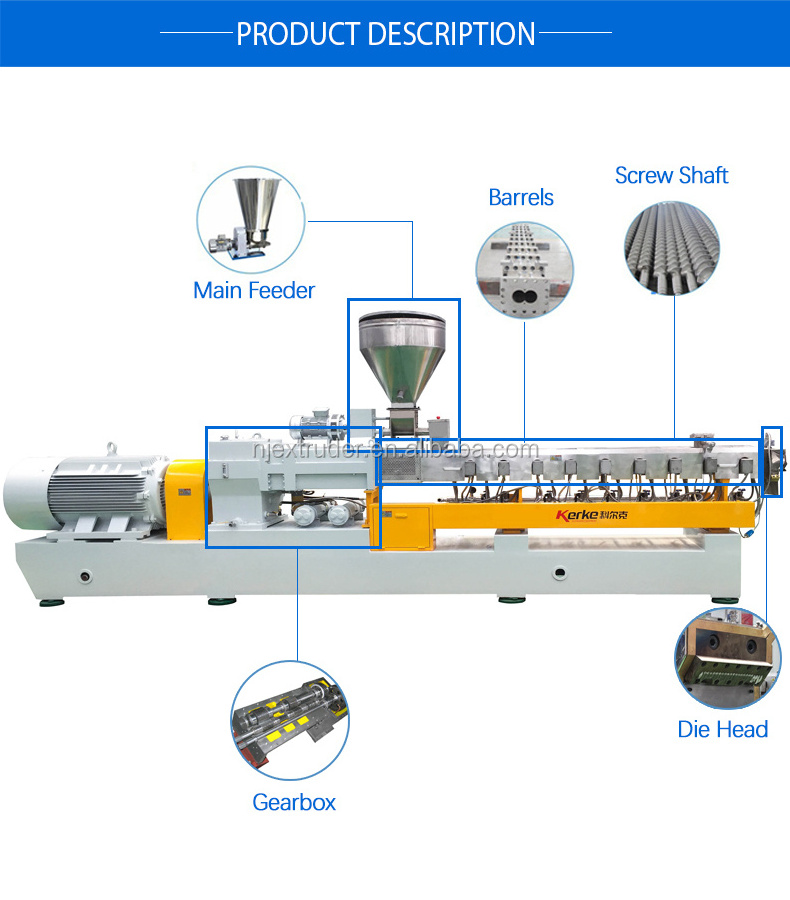

Plastic Polymer Granule Making Machine With CE

| Equipment Model | KTE-65D |

| Screw Diameter(mm) | 62.4 |

| Screw Length To Diameter Ratio | 28-60 |

| Screw Speed(r/min) | 800 |

| Main Motor Power(KW) | 110/132 |

| Screw Torque(N.m) | 1432 |

| Torque Level(T/A³) | 10.3 |

| Typical Operating Capacity(kg/h) | 350~600 |

KTE Series Co-rotating Parallel Twin-screw Extruder Feature s

1.

Screw components design

ed

by computer aids is knead

ing

type, has excellent self-cleaning function, the new kneading block design effectively avoid the problems of overheating and energy consumption.

2.

According to process system and formula requirements,

the unit

can optimize its L/D ratio, barrel structure, screw array, venting number and location, feeding method, electrical control methods etc. for rational allocation.

3. Granulation system: water-cooling strand pelletizing, air-cooling die face hot cutting, water ring die face hot cutting, Eccentric water mist hot cutting, water and underwater die face hot cutting and so on.

4. Application

:

Filling Modification, glass fiber (carbon fiber) enhance various kinds of master batch,

rubber and plastics compounding, plastic alloys, functional master batch, Various kinds of

electric cable

material

,

reactive extrusion. Devolatilization process, powder coating and so on..

Security Protection

:

1.

coupling can effectively protect the reduction gearbox from extrusion unit overload dangers.

2.

water-cooling system and lubrication systems are all real-time online monitoring.

3.

drive

ead pressure and melt temperature are all equipped with alarm system

s

.

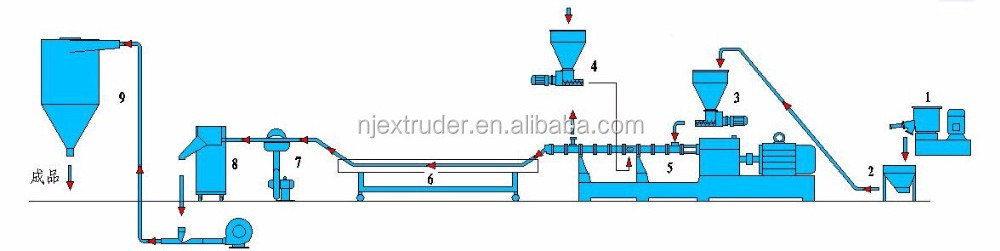

water-cooling strands pelletizer:

1. high-sped mixer 2. solids-conveyer 3. main feeder 4. side feeder

6.twin-screw extruder 7. water trough 8.air-knife 9. pelletizer 10. product container

Application:

1.Fiber reinforcement: glass fiber, carbon fiber reinforced PP,PA,PBT,ABS,AS,PC,POM,PPS,PET,PPO,PSF,LCP,etc.

2.Ploymer blending :bleding of PC+ABS, PA+ABS,CPE+ABS,PP+EPDM,PA+SBS,etc.

3.Incorporation of fillers :CaCO3,Tale,TiO2,carbon black filled PE,PP,or EVA etc.

4.Cable Compounds:cable sheath,cable insulation compounds of LDPE,HDPE,LLDPE,MDPE;radiation-crosslinkable compounds ,optical fiber protection compounds ,heat-shrinkable polymer compounds.

5.Special Compounds :PPR pipe compounds,PE compounds for crosslinked pipes,tobacco filter

compounds,etc

6.High Concentration Color Masterbatches: PE,ABS,PS,EVA,PET,PP etc. With high concentration of pigments and other procrssing aids.

7.Masterbatches with Flame Retardants:PP,PA,ABS,EVA,PBT etc.with flame retardants and other

additives.

8.Special Functional Masterbatches :Masterbatches with anti-static,anti-abcteria ,or other

special functional fillers.

9.Masterbatches for Degradable Polymers:PP,PE,PS etc. Blended with high concentration of

starch and other processing aids.

Air-cooling strands pelletizer system

1.

high-sped mixer

2. solids-conveyer

3. main feeder

4.

side feeder

5.

belt

c

onveyor

6.

air-knife

Application :

This Pelletizing extruder is used to the PP non woven Fabric masterbatch, PS Anti-flame masterbatch, Degradable masterbatch, etc.

Air-cooling hot-face pelletizer

1. high-sped mixer 2. solids-conveyer 3. feeder 4.twin-screw extruder

5. ari-cooling hot-face pelletizer 6.cyclone 7.vibrating sleve

Application :

Enforcing modification PE,EVA etc.+CaCO3 ,talc,TiO2,carbon black.

Degradable master batch:PE,PS etc. + starch,additive etc.

Anti-flame master batch :PE,EVA etc. +Sb2O3,Mg(OH)3 etc.

water-ring hot-face pelletizer

1.high-speed mixer 2. main feeder 3. side feeder 4. twin-screw extruder 5. water ring granulator

6.centrifugal off-water machinery 7.vibrating sieve 8. product container

Application:

1.PE,EVA etc. ,filled with CaCO3,talc,TiO2,carbon black etc.

2.Cable sheath , cable insulation compounds of LDPE,HDPE,LLDPE,or MDPE;

3.PPR pipe compounds,PE compounds for crosslinked pipes;

4.TPR,TPU TPV thermoplastic elastomers; EVA and hot-melt adhesives

5.Color concentrates of PE,ABS,PS,EVA etc;

6.Flame retardant masterbatcher of ABS,EVA etc;

7.Masterbatches with PE,PP,PS etc. As carriers for degradation applications.