- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

31.4 kN

-

Theoretical Shot Volume(cm³):

-

226 cm³

-

Injection Rate (g/s):

-

143 g/s

-

Injection Weight (g):

-

206 g

-

Screw diameter (mm):

-

40 mm

-

Weight (KG):

-

4300

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

400 mm

-

Model Number:

-

SZ-1300A

-

Brand Name:

-

SZ

-

Power (kW):

-

13 kW

-

Product name:

-

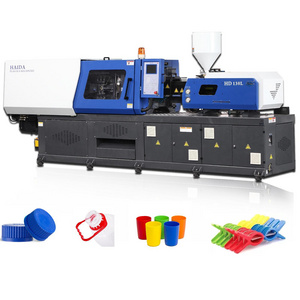

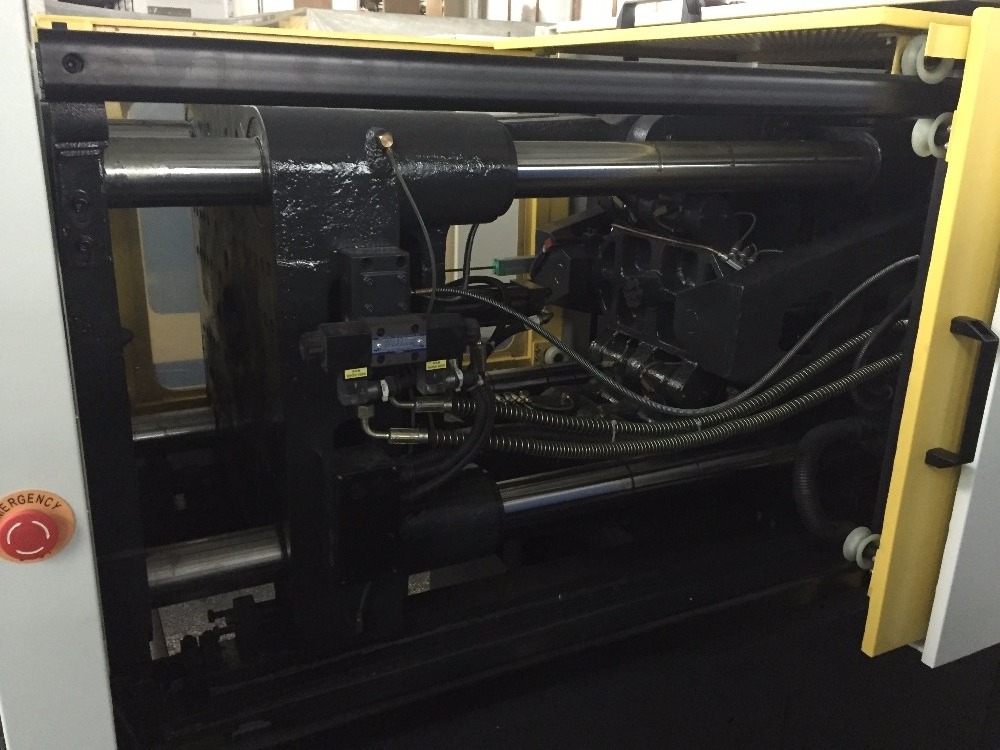

injection molding machine High quality&Competitive price

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Keyword:

-

plastic bottle cap making machine

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

yes

-

Advantages:

-

Energy saving and high efficiency

-

Function:

-

for plastic product

-

Oil Tank Capacity:

-

360L

-

Injection pressure:

-

180Mpa

-

Machine dimension(L*W*H):

-

4.7*1.25*1.85m

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Peru, Russia, Romania, Nigeria, Uzbekistan

-

Certification:

-

CE&SGS&ISO

-

Marketing Type:

-

New Product 2021

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

420mm

-

Distance between Tie Bars(Height)(mm):

-

420mm

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

31.4 kN

-

Theoretical Shot Volume(cm³):

-

226 cm³

-

Injection Rate (g/s):

-

143 g/s

-

Injection Weight (g):

-

206 g

-

Screw diameter (mm):

-

40 mm

-

Weight (KG):

-

4300

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

400 mm

-

Model Number:

-

SZ-1300A

-

Brand Name:

-

SZ

-

Power (kW):

-

13 kW

-

Product name:

-

injection molding machine High quality&Competitive price

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Keyword:

-

plastic bottle cap making machine

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

yes

-

Advantages:

-

Energy saving and high efficiency

-

Function:

-

for plastic product

-

Oil Tank Capacity:

-

360L

-

Injection pressure:

-

180Mpa

-

Machine dimension(L*W*H):

-

4.7*1.25*1.85m

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Peru, Russia, Romania, Nigeria, Uzbekistan

-

Certification:

-

CE&SGS&ISO

-

Marketing Type:

-

New Product 2021

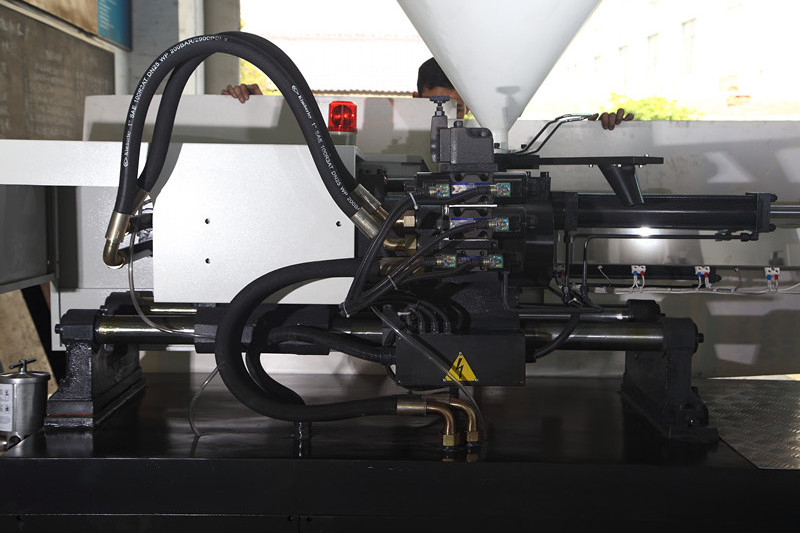

Product Description

|

SZ—1300A Technical parameter

|

|

|

|

|

||||

|

INJECTION UNIT

|

|

|

|

|

||||

|

ITEM

|

UNIT

|

VALUE

|

|

|

||||

|

SCREW DIAMETER

|

mm

|

35

|

40

|

45

|

||||

|

SCREW L/D RATIO

|

L/D

|

24

|

21

|

18.7

|

||||

|

Theoretical Shot Volume

|

cm^3

|

173

|

226

|

286

|

||||

|

SHOW WEIGHT(PS)

|

g

|

158

|

206

|

260

|

||||

|

INJECTION PRESSURE

|

Mpa

|

235

|

180

|

142

|

||||

|

THEORETICAL INJECTION RATE(PS)

|

g/s

|

110

|

143

|

181

|

||||

|

PLASTICISING CAPACITY

|

g/s

|

13.8

|

19.7

|

27.1

|

||||

|

SCREW TORQUE

|

N.m

|

740

|

|

|

||||

|

MAX.SCREW ROTATE SPEED

|

r/min

|

250

|

|

|

||||

|

INJECTION STROKE

|

mm

|

180

|

|

|

||||

|

CLAMPING UNIT

|

|

|

|

|

||||

|

ITEM

|

UNIT

|

VALUE

|

|

|

||||

|

MAX.CLAMPING FORCE

|

KN

|

1300

|

|

|

||||

|

MAX.OPENING STROKER

|

mm

|

400

|

|

|

||||

|

SPACE BETWEEN TIE BARS

|

mm

|

420*420

|

|

|

||||

|

MOULD HEIGHT

|

mm

|

160—440

|

|

|

||||

|

MAX.DAYLIGHT

|

mm

|

840

|

|

|

||||

|

EJECTOR FORCE

|

kn

|

31.4

|

|

|

||||

|

EJECTOR STROKE

|

mm

|

100

|

|

|

||||

|

EJECTOR QUANTITY

|

pc

|

5

|

|

|

||||

|

OTHER

|

|

|

|

|

||||

|

ITEM

|

UNIT

|

VALUE

|

|

|

||||

|

PUMP MOTOR POWER

|

KW

|

13

|

|

|

||||

|

PUMP PRESSURE

|

Mpa

|

16

|

|

|

||||

|

HEATING POWER

|

KW

|

9.2

|

|

|

||||

|

HEATING ZONE

|

|

4

|

|

|

||||

|

SIZE

|

m

|

4.7*1.25*1.85

|

|

|

||||

|

NET WEIGHT

|

t

|

4.3

|

|

|

||||

|

OIL TANK CAPACITY

|

L

|

360

|

|

|

||||

|

INTERNATIONAL DESIGNATION

|

|

1300—410

|

|

|

||||

Why Choose Us

1. 20 years of professional injection molding machine and mold manufacturer, excellent quality, honest management

2. Continuous technological innovation, optimized product structure, longer service life

3. Lifetime maintenance of the product, 24 hours after-sales service

4. The main components are all world-renowned brands

5. Dedicated quality control department

6. Ex-factory price

Hot Searches