- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FreChem

-

Color:

-

White

-

Product name:

-

PTFE powder

-

Material:

-

100% Virgin PTFE

-

Name:

-

Natural Ptfe powder

-

Certification:

-

ISO

-

Purity:

-

99% PTFE Powder

-

Exterior:

-

White Fine Powder

-

Average particle size:

-

400-900um

Quick Details

-

color:

-

white

-

Shape:

-

powder

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FreChem

-

Color:

-

White

-

Product name:

-

PTFE powder

-

Material:

-

100% Virgin PTFE

-

Name:

-

Natural Ptfe powder

-

Certification:

-

ISO

-

Purity:

-

99% PTFE Powder

-

Exterior:

-

White Fine Powder

-

Average particle size:

-

400-900um

| PTFE fine resin | |||

| Main Technical Properties | |||

| FR-D01 | FR-D02 | FR-D03 | |

| Appearance | White loose powder | White loose powder | White loose powder |

| Tensile strength, Mpa | 28 | 20 | 32 |

| Elongation at break, %≥ | 350 | 350 | 350 |

| Bulk density, g/L | 375-575 | 375-575 | 375-575 |

| Average size, d50 µ m | 400-900 | 400-900 | 550-750 |

| Moisture, % ≤ | 0.03 | 0.03 | 0.03 |

| Extrusion pressure(RR100:1)Mpa | 5.5+13.9 | 5.5-13.9 | 14.5-40.5(RR400:1) |

| Standard specific gravity | 2.14-2.19 | 2.17-2.20 | 2.14-2.19 |

| Thermal Instability Index, ≤ | 30 | 30 | 30 |

| Extrusin pressure | Continuous, even,smooth | Continuous, even,smooth | Continuous, even,smooth |

| Product characters: |

1.Has high tensile strength,can make wide seal tape. 2.To make 4-12mm white extruded tube. 3.To make 16mm extruded rod. |

1. Make color wide seal tape, color is unform and no spot. 2. Make various extruded tube, color is uniform. |

Make various extruded tube, use repid cooling process to improve tube transparency |

| Application | Make extruded tube,rod,tensile,film,seal tape, etc | .Make extruded tube, rod, tensile,film, seal tape, etc. | Make extruded tube,rod, tensile,film, seal tape,etc. |

PTFE free flow (Pelletized) resin

| FR-F01 | FR-F02 | FR-F03 | |

| Apperance | White powder, no impurities | White powder, no impurities | White powder, no impurities |

| Tensile strenght(Mpa, ≥ ) | 22.5 | 22.5 | 22.5 |

| Elongation at Break(%, ≥ ) | 275 | 275 | 275 |

| Bulk Density (g/L) | 750 ±150 | 750 ±150 | 750 ±150 |

| Average particle size,d50 (um) | 200-400 | 401-600 | 601-900 |

| Moisture(%, ≤ ) | 0.02 | 0.02 | 0.02 |

| Melting point(℃) | 375 ±5 | 375 ±5 | 375 ±5 |

| S.S.G. | 2.13-2.19 | 2.13-2.19 | 2.13-2.19 |

| Thermal Instability Index( ≤ ) | 30 | 30 | 30 |

| Characters | The partial size is small and fluidity is good. It can be added to various small moulds. | Can make mult-angle automatic molding products. | The partial size is round and has good fluidity.It can mix with other resin. |

| Application | Make molding rod,tub,plate, suitable for automatic estrusion. | Make molding rod, tub,plate,suitable for automatic extrusion. | Make molding rod, tub, plate, can use as engineering plastic additive. |

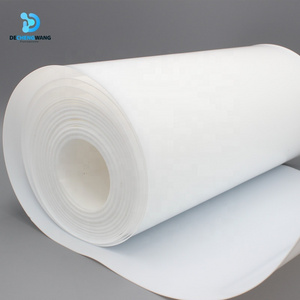

Modified PTFE fine powder for PTFE membrane

|

|

FR-MD08 |

FR-MD18 |

FR-MD88 |

|

Appearance |

White powder |

White powder |

White powder |

|

Standard specific gravity |

2.16-2.17 |

2.15-2.16 |

<2.15 |

|

Tensile strength(Mpa ≥) |

26 |

26 |

26 |

|

Elongation at Break(% ≥) |

260 |

260 |

260 |

|

Average particle size( µ m) |

550±200 |

550±200 |

550±200 |

|

Application |

Suitable for Water treatment hollow fiber membrane and so on. |

Single, biaxially stretched film, extruded tube, elastic plate, clothing film, medical filter film, etc. |

Air filtration membrane and so on. |

PTFE Dispersion liquid

|

|

FR-E60A |

FR-E60D |

FR-E60F (PFOA free) |

|

Appearance |

White liquid |

White liquid |

White liquid |

|

PTFE content (%) |

60±2 |

60±2 |

60±2 |

|

Surfactant(%) |

4.0-7.0 |

4.0-7.0 |

4.0-7.0 |

|

PH |

8-10 |

8-10 |

8-10 |

|

Viscosity, x10-3Pa.s |

20-40 |

20-40 |

20-40 |

|

Characters |

1.Has good stability, suitable for any mixing process. 2.The content of surfactant helps to increase wetting and sticking. 3.Has high molecular weight and suitable for high temperature cooling process, to improve the polish the appearance. |

1. Has good wetting performance, especially for impregnation of glass fiber. 2.Has good dispersion performance, can mix with other dispersion |

1.Has good stability, suitable for any mixing process. 2.The content of surfactant helps to increase wetting and sticking. 3.Has high molecular weight and suitable for high temperature cooling process, to improve the polish the appearance. |

|

Application |

Impregnation of glass fiber and asbestos, anti-sticky coating. |

Impregnation of glass fiber and asbestos |

Impregnation of glass fiber and asbestos, anti-sticky coating. |

PTFE-Product detail

APPLICATIONS

Non-stick coating, gaskets, packings, bearings, high and low temperature electrical and medical applications, laboratory equipment, pump parts, thread seal tape.

PROPERTIES

Semi-rigid, translucent, exceptional low friction characteristics, superior chemical resistance, imperious to fungi or bacteria, high temperature stability (260'C), low temperature toughness (-160'C), good weathering resistance and electrical properties.

USED

As an additive for plastics ,rubbers and powder coatings to improve non-stick properties ,reduce coefficient of friction ,improve wear resistance of the matrix and processing behavior.

Advantages

High temperature resistant, use the working temperature of 250 ℃.

Low temperature resistance -- good mechanical toughness;Even if the temperature drops to 196 ℃, also can keep 5% elongation.

Corrosion resistance - shows resistance to most chemicals and solvents, strong acid and alkali, water and various organic solvents.

Weather-resistant - has the best aging life in plastics.

High lubrication - lowest friction coefficient of solid materials.

Nonadhesion - is the minimum surface tension in a solid material that does not adhere to any material.

Non-toxic - with physiological inertia, as artificial blood vessels and organs long-term implanted in the body without adverse reactions.

Electrical insulation - resistance to 1500 v high voltage.

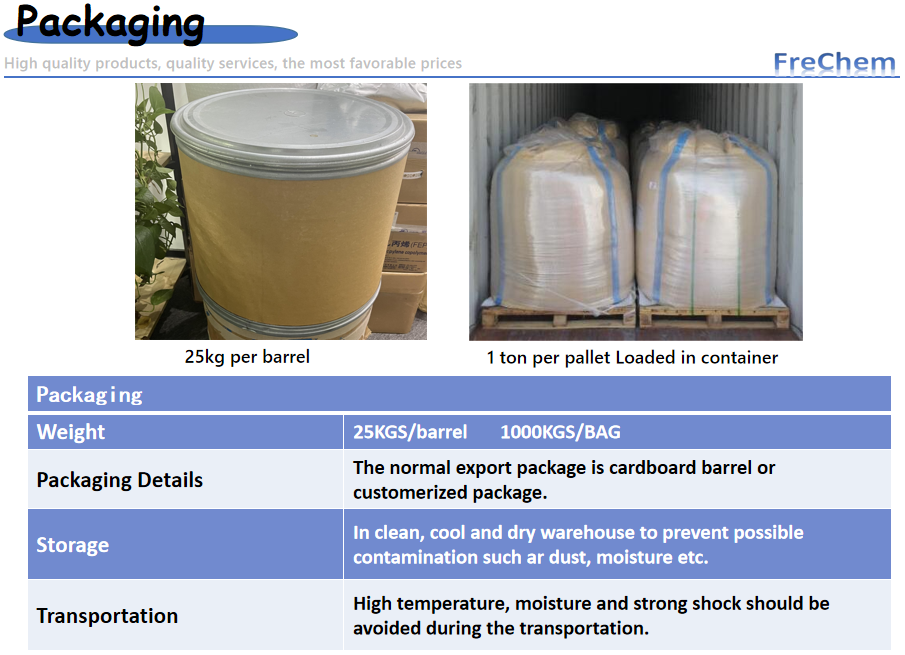

Package :

Packed with sealed PE bag outside, load in waterproof paper barrel. The net weight is 20/25 + 0.1kg per barrel, then stack on a pallet.(PTFE dispersion liquid:25/1335 + 0.1kg per barrel)

It should be stocked in clean, cool and dry warehouse, prevent from agglomeration and contamination.

Shipping:

Nontoxic, noninflammable, inexplosive, no corrosion, the product is transported according to non-dangerous product.

Normally, one week for samples and Within 3 weeks after payment for others.

Production orders can be arranged specially to meet customer’s urgent demands.

JIANGSU FRECHEM CO., LTD limited in Jiangsu Nanjing, which is an expert in new material area. Engaged in research & development, productionand sales of engineering fluoroelastomer including FKM\ PFA\ PVDF\ PTFE\ PVDC\ FEP etc. Materials can be widely used in cars, electrical appliances, electronic, medical, industry, etc.

Q: please tell me about the ptfe powder used for what area?

A: It is mainly used for project plastic, rubber, coating, printing ink, lubricant oil, lubricant grease, cosmetics, medical instruments and other fields.

Q: Can you provide a free sample?

A: Less than 200g can be provided free, and freight shall be paid by the buyer. Or you can also buy a small amount of product, $15/kg, you need to pay the freight.

Q:can you reply any professional questions if I have some ?

A:Of course! we manage this kind of products over18 years ,and our technicians can provide you with best comprehensive and expert answers,so you can tell us what you want and need without hesitation.

Q::what payment terms can you accept?

A:L/C T/T is our perference, but we shall take your advices according to particular condition.

Q:can I contact you in time?

A: Trade manager is always waiting for you !

Contact me