- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Glow Pigment

-

Keywords:

-

Glow powder

-

Application:

-

Resin Art/DIY

-

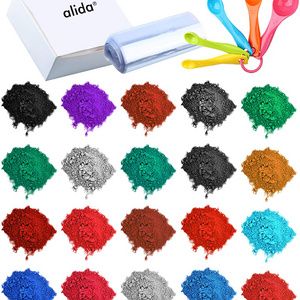

Color:

-

Customized

-

MOQ:

-

1KG

-

Package:

-

customized

-

Material:

-

Mica Material

-

Colors:

-

12 colors

Quick Details

-

Other Names:

-

Pigment

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

CNMI

-

Product name:

-

Glow Pigment

-

Keywords:

-

Glow powder

-

Application:

-

Resin Art/DIY

-

Color:

-

Customized

-

MOQ:

-

1KG

-

Package:

-

customized

-

Material:

-

Mica Material

-

Colors:

-

12 colors

Recommend Products

Product Description

CNMI Glow Powder for Art Craft Nail Acrylic Paint Skin Safe Long Lasting Self Glowing Dye Fluorescent Powder Luminous Powder

Our glow in the dark pigment can be mixed in nail acrylics, glues, plastics, paint, ink, ceramics, glass, plastisol, enamel,

epoxy, resins, acrylic, ice, clay, rubber, silicone, wax, and much more. We sell only the brightest and longest lasting glow

powder of each color, type and size.

Phosphor pigment is a special kind of pigments that convert absorbed light into longer wavelengths of fluorescence reflection.This fluorescence plus normal reflected light makes the color of phosphor particularly bright.Our effect pigments includes fluorescent neon color pigments, glow in the dark pigments, thermochromic pigments, photoluminescent pigments etc. The luminous effect pigments are widely used by consumers and businesses to make craft projects, decorative cosmetics, make safer work and home environments, fishing widgets, and for hundreds of other extremely useful projects.

epoxy, resins, acrylic, ice, clay, rubber, silicone, wax, and much more. We sell only the brightest and longest lasting glow

powder of each color, type and size.

Phosphor pigment is a special kind of pigments that convert absorbed light into longer wavelengths of fluorescence reflection.This fluorescence plus normal reflected light makes the color of phosphor particularly bright.Our effect pigments includes fluorescent neon color pigments, glow in the dark pigments, thermochromic pigments, photoluminescent pigments etc. The luminous effect pigments are widely used by consumers and businesses to make craft projects, decorative cosmetics, make safer work and home environments, fishing widgets, and for hundreds of other extremely useful projects.

Product Details

|

Product Name

|

|

CNMI Glow Powder for Art Craft Nail Acrylic Paint Skin Safe Long Lasting Self Glowing Dye Fluorescent Powder Luminous Powder

|

|

|

|||

|

Usage

|

|

Toys, Clothes, Paint, Ink, Ceramic Pigments, Coating Pigment, Cosmetic Pigment, Ink Pigments, Plastic & Rubber Pigment, Leather Pigments, Clothes Pigment,Leather, Ink, Painting, Coating, Plastic, Printing

|

|

|

|||

|

Feature

|

|

Non-Radioactive, Non-Toxic, Vivid Color, Harmless, Good coloring, Uniformity, High Brightness, Easy to get light source, Excellent physical and chemical characteristics,Good stability, Strong environmental adaptability, High temperature resistant, Safe and reliable, Energy conservation, Environmental protection.Absorbing light time is short, afterglow time is long.good solvent resistance

|

|

|

|||

|

Solubility

|

|

Insoluble in Organic Solvent/Strong Acids/Strong Alkalines/Water

|

|

|

|||

|

Luminous Time

|

|

About 8 Hours

|

|

|

|||

|

Thermostability

|

|

1000 Degrees

|

|

|

|||

How to operate the glow powder

The proportion of the glow powder can be adjusted by the weight of 1:1.

1).The firstly You should add a luminous powder and then slowly adding ink or paint or solvent, when ink or painting or solvent covered luminous powder, please stop.

2). after about half an hour to 1 hours (how much time waiting is, according to the situation) When glow powder can be fully wet by ink or painting or solvent, then add the remaining ink or painting or solvent, then mixing. This process will avoid producing bubbles.

3). Before brushing the glowing paint, to add a white substrate on the surface objects or directly brush the glowing paint on white material, which can improve the brightness and extend light time. If the bottom color is dark, the brightness will be reduced. Thickness of glowing layer should not be lower than 100um. So should choose 80-120 mesh silk-screen.

4). Glowing ink or painting After drying, brushing a layer of varnish with good water resistance for improving water resistance and surface smooth of products.

1).The firstly You should add a luminous powder and then slowly adding ink or paint or solvent, when ink or painting or solvent covered luminous powder, please stop.

2). after about half an hour to 1 hours (how much time waiting is, according to the situation) When glow powder can be fully wet by ink or painting or solvent, then add the remaining ink or painting or solvent, then mixing. This process will avoid producing bubbles.

3). Before brushing the glowing paint, to add a white substrate on the surface objects or directly brush the glowing paint on white material, which can improve the brightness and extend light time. If the bottom color is dark, the brightness will be reduced. Thickness of glowing layer should not be lower than 100um. So should choose 80-120 mesh silk-screen.

4). Glowing ink or painting After drying, brushing a layer of varnish with good water resistance for improving water resistance and surface smooth of products.

Product Application

Hot Searches