- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

0.1/0.18/0.2/0.3MM

-

Product name::

-

0.18 mm molybdenum wire

-

Material:

-

Tungsten Carbide WC+Co

-

Length:

-

1200 ~ 2000m

-

Surface:

-

Polishing

-

Application:

-

Wire-electrode cutting

-

Tensile Strength::

-

≥2000N/mm2

-

Mo:

-

≥99.5%

-

Dia tolerance::

-

±2%

-

Length tolerance::

-

0~(+0.06)

Quick Details

-

Dimensions:

-

customized, customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JDC

-

Model Number:

-

0.1/0.18/0.2/0.3MM

-

Product name::

-

0.18 mm molybdenum wire

-

Material:

-

Tungsten Carbide WC+Co

-

Length:

-

1200 ~ 2000m

-

Surface:

-

Polishing

-

Application:

-

Wire-electrode cutting

-

Tensile Strength::

-

≥2000N/mm2

-

Mo:

-

≥99.5%

-

Dia tolerance::

-

±2%

-

Length tolerance::

-

0~(+0.06)

Product Description

Product Information

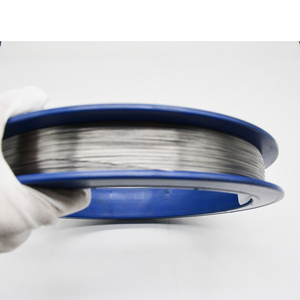

Product Name : wholesale 0.18mm edm molybdenum wire

Standard : ASTM B387

Material : Molybdenum

Purity : 99.95%

Density : >10.2g/cc

Standard : ASTM B387

Material : Molybdenum

Purity : 99.95%

Density : >10.2g/cc

Application:

Molybdenum wire can withstand high temperature and corrosion, it is used as heating materials of high-temperature resistance furnace, heating elements, automotive, aerospace, wire cutting machine; With good electrical conductivity, molybdenum wire also can be applied to electronic tube socket, stent filament incandescent lamp, halogen lamps, discharge tube sealing material, lead-wire, tungsten filament with the mandrel, the grid. There are some other common uses for molybdenum wire such as cathode, spray material.

Specification:

Our molybdenum wire is produced by stretching the Molybdenum rod to various diameter after the rod undergo the pass rolling and rotary forging to about 3mm. The Advantages of our molybdenum wire are with good stability, good tensile strength, high precision cutting and low elongation. Our factory can provide various of molybdenum wires with the diameter among 0.18~3.0mm, we can also provide custom products as your requirements. We offer 2,000 to 3,000 kg pure molybdenum wire products per month. Standard availability is described below. Other sizes and tolerances are available.

|

Molybdenum Wire Type

|

Diameter(Inch)

|

Tolorance

|

|

Molybdenum Wire for EDM

|

0.007"~0.01"

|

±3%wt

|

|

Molybdenum Spray Wire

|

1/16"~1/8"

|

±1%~±3%wt

|

|

Molybdenum Wire

|

0.002"~0.08"

|

±3%wt

|

|

Molybdenum Wire (Clean)

|

0.006"~0.06"

|

±3%wt

|

Dimensions and Tolerances:

Wire diameters are generally expressed in terms of inches or mils (thousandths of an inch). For thin wires from 0.001 inches up to 0.020 inches, the size of the wire is measured by weight per unit length. That is, the weight expressed in mg of a 200mm length of wire.The standard diameter tolerance is ±3% of the weight measurement. For mandrel applications, the tolerance is normally ±1%.

Tensile Strength:

Tensile strength for molybdenum wire is usually expressed in grams per milligram weight of a 200 millimeter length (or)

g/mg/200mm. The normal range of values is 40 to 60 grams. In general, as tensile strength increases, wire straightness decreases.

g/mg/200mm. The normal range of values is 40 to 60 grams. In general, as tensile strength increases, wire straightness decreases.

Straightness:

The measure of the straightness of a metal wire is obtained by cutting a ten inch long piece of wire and allowing it to lie on a flat clean surface. The maximum deviation from a straight line along its length is the quantitative measure of its straightness.In general, as the degree of the straightness increases, tensile strength decreases.

Characteristic of cleaned Molybdenum wires:

|

Name

|

Specific Property

|

Application

|

|

Molybdenum wires cleaned by electrolysis

|

The aquadag layer can be removed by electrolysis.

|

Mandrels of tungsten coiled coil

|

|

Molybdenum wires cleaned in hydrogen atmosphere

|

The aquadag layer can be removed in hydrogen atmosphere.

|

Used in making supports of various type of bulb

|

Product Show

Packing & Delivery

Customer Photos

Hot Searches