- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2023

-

Production Capacity:

-

400 t/h

-

Power:

-

225

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

12000*2500*3750mm

-

Product name:

-

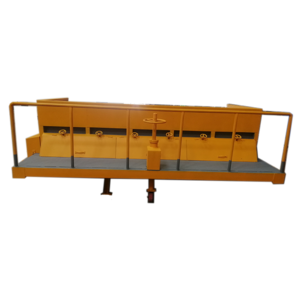

Chip Spreader Truck

-

Application:

-

Road Construction Leveling

-

Key words:

-

Asphalt Paver Machine

-

Spray medium:

-

gravel and asphalt

-

Paving Width:

-

4000mm

-

Engine:

-

420hp

-

Max. paving width:

-

4000mm

-

Hopper capacity:

-

20 T

-

Asphalt spreading amount:

-

0.2~4.0kg/m2

-

heating method:

-

Imported diesel burner (200,000 kcal/hour)

Quick Details

-

Max. Paving Thickness:

-

3-24mm

-

Weight:

-

19980 kg

-

Engine Brand:

-

WEICHAI

-

Marketing Type:

-

New Product 2023

-

Production Capacity:

-

400 t/h

-

Power:

-

225

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

12000*2500*3750mm

-

Product name:

-

Chip Spreader Truck

-

Application:

-

Road Construction Leveling

-

Key words:

-

Asphalt Paver Machine

-

Spray medium:

-

gravel and asphalt

-

Paving Width:

-

4000mm

-

Engine:

-

420hp

-

Max. paving width:

-

4000mm

-

Hopper capacity:

-

20 T

-

Asphalt spreading amount:

-

0.2~4.0kg/m2

-

heating method:

-

Imported diesel burner (200,000 kcal/hour)

Product Description

Specification

|

item

|

value

|

|

Applicable Industries

|

Building Material Shops, Machinery Repair Shops, Construction works , Energy & Mining, Other

|

|

Showroom Location

|

Viet Nam, Peru, Indonesia, Kenya, Chile, Colombia, South Africa, Kazakhstan, Kyrgyzstan, Uzbekistan

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2023

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Engine, Motor

|

|

Condition

|

New

|

|

Production Capacity

|

400 t/h

|

|

Power

|

225

|

|

Max. Paving Thickness

|

3-24mm

|

|

Place of Origin

|

China

|

|

Dimension(L*W*H)

|

12000*2500*3750mm

|

|

Weight

|

19980kg

|

|

Hydraulic Pump Brand

|

famous

|

|

Hydraulic Valve Brand

|

famous

|

|

Engine Brand

|

WEICHAI

|

|

UNIQUE SELLING POINT

|

Fully hydraulic system

|

|

Product name

|

Chip Spreader Truck

|

|

Application

|

Road Construction Leveling

|

|

Key words

|

Asphalt Paver Machine

|

|

Spray medium

|

gravel and asphalt

|

|

Paving Width

|

4000mm

|

|

Engine

|

420hp

|

|

Max. paving width

|

4000mm

|

|

Hopper capacity

|

20 T

|

|

Asphalt spreading amount

|

0.2~4.0kg/m2

|

|

heating method

|

Imported diesel burner (200,000 kcal/hour)

|

HOWO 8*4 Chip Spreader Truck

◆

Spreading width: 4000mm

◆ Asphalt spreading amount: 0.2~4.0kg/m2

◆ Heating method: Imported diesel burner (200,000 kcal/hour)

◆ Full load mass: 45t

◆ Empty weight: 17.6t

◆ Spraying medium: hot asphalt, thermally modified asphalt, diluted asphalt, emulsified asphalt, etc. If rubber modified asphalt needs to be sprayed

(Should meet the following two conditions: 1. Rubber modified asphalt viscosity Haake190℃ 1500~2200Pa.s; 2. Rubber modified asphalt spraying temperature 200~210℃; 3. Rubber modified asphalt spraying width 4000mm)

◆ Spreading material specification: S3~S24mm

◆ Spreading accuracy: ±2%

◆ Bitumen tank capacity: 8m3

◆ Silo capacity: 12m3

◆ Dimensions:

12000

×2500×

3750mm

Equipment composition and structural features

The synchronous gravel truck is mainly composed of asphalt spreading system, stone material spreading system, electrical operating system and auxiliary system.

Asphalt Spraying System Spraying system mainly consists of asphalt tank, heating part, hydraulic part, control part and spraying part.

1. Asphalt tank The outer wall of the tank is made of stainless steel frosted plate, with insulation filler in the middle, and the inside is composed of a heating boiler and a heat transfer oil coil, with a clean and elegant appearance. The air control valve group added outside the tank realizes the large and small circulation of asphalt in the pipeline and avoids local overheating and aging of the asphalt.

2. Heating part The heating device adopts imported burner and matching high-efficiency boiler, which has high combustion efficiency, good atomization effect, low fuel consumption, fast heating speed, safe and stable operation, etc. There is no need for manual monitoring to ensure that the asphalt in the pipeline can obtain an effective heating temperature.

3. The hydraulic part adopts components (hydraulic pump and hydraulic motor) of internationally renowned brands to ensure reliable transmission performance.

4. The control part uses an encoder to accurately detect the speed of the vehicle and the speed of the asphalt pump to ensure the accuracy of spreading. Among them, the radar, encoder and main circuit switching components are all imported components. After setting the spraying amount, the PLC automatically calculates the vehicle speed and pump speed, realizes the automatic control of spraying, and can recommend a reasonable vehicle speed for the driver.

5. Spraying part The opening and closing of each nozzle is controlled by an individual air valve. Through special pipeline design, uniform pressure and good spraying effect are guaranteed.

stone spreading system

The stone spreading system consists of a silo, a material door control mechanism and a spreader.

Inside the silo, there is an inner shadow hidden-type center-top flip shaft and a through shaft to ensure the stability of the silo’s rise; the material door is controlled by 16 channels, and an angle helix angle controller is used to make the material door reach a certain opening degree. The opening angle of the material door can be set on the angle controller, which is very convenient and accurate. Effectively adjust the uniformity of spreading, changing the traditional situation of uneven stone spreading; the adjustment range of the distribution plate and the blanking plate is large, and it is suitable for stones of different specifications (S3-S24mm).

Electrical Operating System

1. Provide operators with accurate spreading parameters according to different work requirements.

Through the setting of the display screen parameters on the rear console, the continuous changes of the actual measurement parameters can accurately reflect the operation of the equipment.

2. Manual operation is simple, and manual/automatic switching can be realized, which improves work efficiency.

3. The width of asphalt spraying and stone spreading can be adjusted at will according to the width of the road surface.

4. The limit switch device is used to control the lifting of the nozzle frame and the material bin to avoid damage to the human machine due to overtravel.

5. Equipped with an automatic alarm device for heat transfer oil, it has the functions of upper limit and lower limit alarm of material level, and alarm indication function of lower limit of asphalt

Equipment Advantages

◆ Exclusive use of full hydraulic drive mode, no need to add any auxiliary power to make the operation easier and more convenient.

◆ Exclusively adopts high-efficiency heat-conducting oil boiler to heat up, so that the temperature rise rate is greatly improved, breaking the traditional flue heating method.

◆ The equipment adopts the internal lifting hopper to realize the spreading construction of stone chips, which is more convenient for culvert construction, under bridge construction, and curved road construction;

◆ The equipment is completely controlled by electricity, with a high degree of automation, and can accurately calculate the amount of asphalt spraying and stone chips spreading during the construction process of the equipment;

◆ Angle meter is used for material door control to ensure the accuracy of equipment blanking;

◆ Reduce the labor intensity of construction, save human resources, reduce construction costs, improve work efficiency and work quality;

◆ The whole machine runs stably, spreads evenly, and can freely adjust the width of asphalt sprinkling;

◆ Good insulation layer ensures that the insulation performance index is ≤20℃/8h, and it is anti-corrosion and durable;

◆ It can spray various asphalt media and spread stones from S3 to S24mm;

◆ The equipment adopts nozzles with high processing precision, so that the spraying consistency and spraying effect of each nozzle are fully guaranteed;

◆ The overall operation is more humanized, with remote control and on-site operation, which brings great convenience to the operator;

◆ Through the perfect combination of electrical control and hydraulic system constant pressure device, zero-start spraying is realized;

◆ The whole machine has undergone many engineering construction improvements, with reliable working performance, convenient operation and maintenance, and high cost performance.

Packing & Delivery

Support Express Sea freight Land freight Air freight

Hot Searches