- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

GM

-

Voltage:

-

380v/480v etc.

-

Power:

-

220kw-250kw

-

Dimension(L*W*H):

-

according to your order

-

Weight:

-

50 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type of machine:

-

kraft paper machine,multi-cylinder mould and multi-dryer can

-

Raw material:

-

waste paper and pure wood pulp and wheat straw

-

Output paper style:

-

corrugated paper, kraft paper,liner paper

-

Net paper width:

-

2400mm

-

Capacity:

-

40t/d

-

Rail gauge:

-

3300mm

-

Drive way:

-

AC inverter speed, section drive.

-

paper weight:

-

40-140gsm

-

Certification:

-

ISO9001:2008

Quick Details

-

Production Capacity:

-

40t/d

-

Product Type:

-

paper product making machinery

-

Processing Type:

-

karton roll production line

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

GM

-

Voltage:

-

380v/480v etc.

-

Power:

-

220kw-250kw

-

Dimension(L*W*H):

-

according to your order

-

Weight:

-

50 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type of machine:

-

kraft paper machine,multi-cylinder mould and multi-dryer can

-

Raw material:

-

waste paper and pure wood pulp and wheat straw

-

Output paper style:

-

corrugated paper, kraft paper,liner paper

-

Net paper width:

-

2400mm

-

Capacity:

-

40t/d

-

Rail gauge:

-

3300mm

-

Drive way:

-

AC inverter speed, section drive.

-

paper weight:

-

40-140gsm

-

Certification:

-

ISO9001:2008

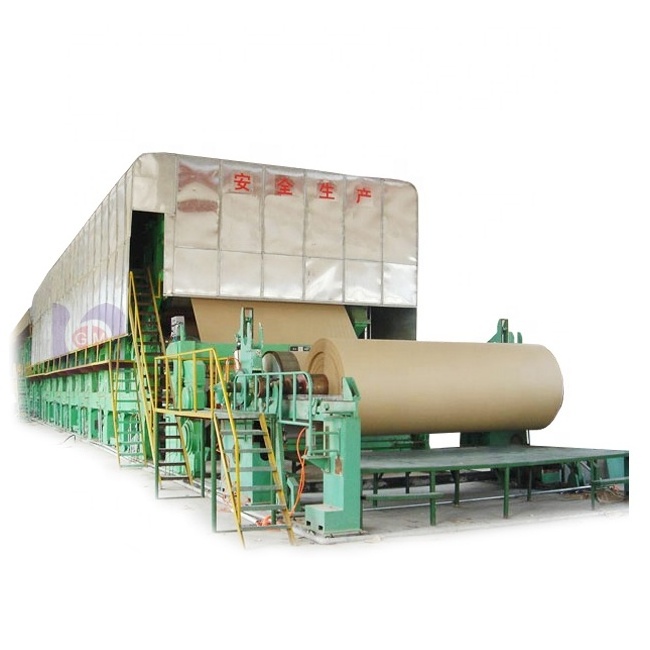

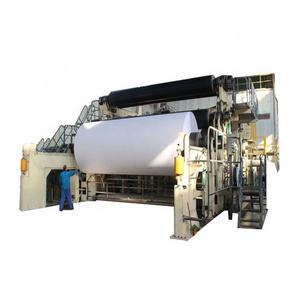

machine de recyclage wheat straw paper pulper machine karton roll production line, Coating white board paper making machine

About paper-making

This production line can use waster paper,recycled paper ,tree ,bamboo ,reed ,wheat straw cotton

and bagasse as raw material to make good quality craft paper,finished product can be paper roll,

tissue paper, toilet paper, culture paper , Kraft paper, newspaper etc. ;

the main work flow is as follows:

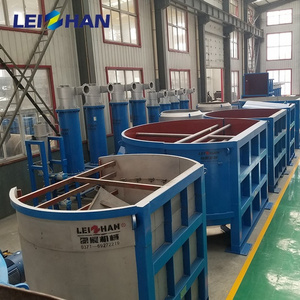

1 pulp making production line

2 glue adding system

3 paper making production line

4 paper converting section

5 boiler section

Technical parameter:

1. Raw material: waste paper and pure wood pulp and wheat straw;

2. Output paper style: Kraft paper;

3. Output paper weight: 40-300gsm;

4. Net paper width: 2400mm;

5. Capacity:40t/d;

6. Width of cylinder mould: 2850 mm;

7. Rail gauge: 3300mm;

8. Drive way: Alternating current, frequency conversion, speed control, section drive;

Structure and characteristic of main part

1. Cylinder section: φ 1250mm×2450mm stainless steel cylinder mould 1 set, φ 450mm× 2450mm couch roll 1 set, φ 400× 2450mm reverse roll 1set, coated by rubber, rubber shore hardness 38 ± 2.

2. Press section: φ 500mm× 2450mm marble roll 1 set, φ 450mm× 2450mm rubber roll 1 set, coated by rubber, rubber shore hardness 90 ± 2.

3. Dryer section: φ 1500mm× 2450mm cast iron dryer can1 set, φ 500mm× 2450mm touch roll 1 set, coated by rubber, rubber shore hardness 90 ± 2.

4. Drive way: Alternating current, frequency conversion, speed control, section drive;

5. Pneumatic compression device

.

| NO. | Item | Qty(set) |

| 1 | 2400mm Kraft paper machine | 1 |

| 2 | exhaust hood of dryer can(double layer) | 1 |

| 3 | Φ 600mm axial-flow ventilator | 1 |

| 4 | 13 type roots vacuum pump | 1 |

| 5 | 2100mm winding machine | 1 |

| 6 | 2100mm calendar | 1 |

| 7 | 1092mm rewinding machine | 1 |

| 8 | 5 m3high consistency hydrapulper | 1 |

| 9 | 1.8 m2high frequency vibrating screen | 1 |

| 10 | 5 m2cylinder pulp thickner | 1 |

| 11 | 0.6 m2pressure screen | 1 |

| 12 | Φ 250mm single disc pulp refiner | 2 |

| 13 | 600 low consistency sand remover | 1 |

| 14 | Φ 700mm thruster | 4 |

| 15 | 4inch pulp pump | 4 |

| 16 | 6inch pulp pump | 4 |

| 17 | 1ton boiler(burn coal) | 1 |

raw material for making kraft paper: waste paper, virgin pulp, wood, old carton box, straw pulp, sugarcane bagasse pulp etc.

finisehd product : jumbo roll kraft paper, white top liner paper, duplex board paper, fluting paper, paper core etc.

flow charts for making kraft paper:

Pulp making equipments: pressure screen, slag separator, hydrapulper, pulp thickener, desander etc.

paper machine main parts : machine frame, dryer can, vacuum roll, exhaust hood, vacuum suction box, guide roll, doctor blade.

drawing of hot selling 2400mm kraft paper production line as follows:

More details:

Packaging

1. Fixed all the movable parts with plastic films.

2. Polystyrene foam plate wrapped around.

3. Wrapped with tighted plastic films several circles.

4. Fixed machine on the fumigated plywood pallet with iron wire.

5. Wrapped with wooden board around and nailed on.

Shipments;

1 sea transportation is from qingdao seaports or other ports.

2 the delivery time is decided by your needed machines or machine parts. But it also follows your needs.

How to get your suitable machine and production lines?

1.inquiry:contact us by email,phone,fax,skype,MSN etc.

2.negotiation:after getting our quotation,you confirm the paper machine model and specify the items you desire.

3.contract:place order and signing the agreement files.

4.production:as soon as we received first payment,we will start to produce machines.we will notify client to book the ship 15days in advance.

5.delivery: all the machines will be shipped according to contracted items.

6.installation:we will send engineers/technicians to install the whole production line.

After-sales service

1. Our company view adhering to the "excellent quality, customer satisfaction" service concept, to provide you with excellent products and perfect service.

2. Our company keep the contract and reputation. Quality first, products guarantee a year, as it is quality problem, free replacement.

3. For every purchase of our company's products, the company can send technicians to guide the installation and debugging, and can undertake the design of process and equipment installation.

4. Our company ensure that supply of parts discount all the year round.

whole production line :

1.Chain conveyor

2.Hydraupulper, D-type hydraupuler, Drum type hydraupulper

3.High density de-slagging machine

4.Vibrating screen, mid consistency pressure screen, paper machine pressure screen, UV-flow pressure screen, inflow pressure screen,external flow pressure screen, center section energy saving pressure screen,fiber fractionating screen,light rejects screen,double drum pressure screen, coarse screen , fine pulp screen etc.

5.PZ series reject separator, Single-effect separating machine,, single fiber separating High Quality Heavy Impurity Cleaner/waste paper recycling processing machine/paper pulp making machines machine etc.

6.Pulp pump

7.Double disc refiner, high taper fine grinding machine, double disc pulp grinding machine, conical refiner etc.

8.High taper helical propeller, square pulp pool stirrer

9.Other paper recycling machines such as grapple, cutter,drum unpacker., disc thickener, sludge dewatering machine etc.

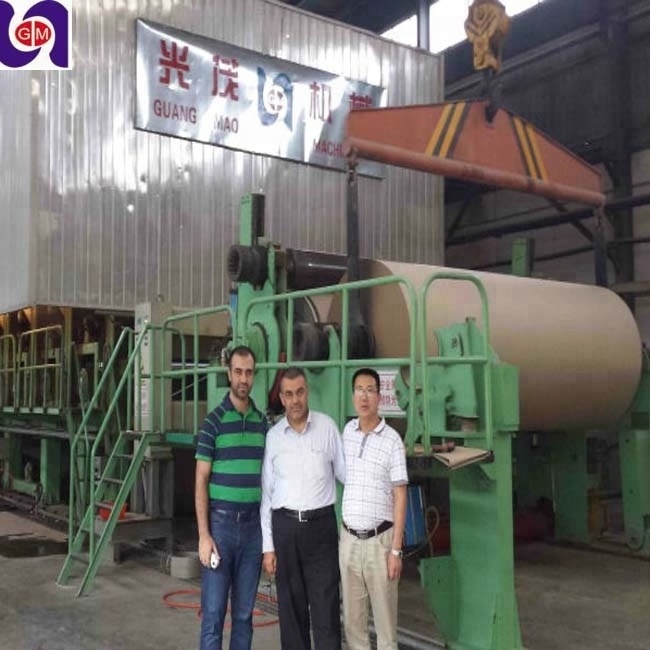

Company introduction:

A.Our company undertakes design, manufacturing, supply, erection and commissioning of paper machines & new pulp mill and modernization of existing pulp mill and paper machines on a turnkey basic.

B. We are professional in manufacturing all kinds of paper machine, tissue paper machine, craft paper machine, printing paper machine, coated paper machine.

Trade market:

Our machines sell good in more than 30 countries,such as Nigeria, Egypt, Uzibekistan, Pakistan, America,Uganda,Turkey,Brazil,Fiji,Paraguay,Ethiopia,etc.We have established good relationship with many foreign countries because of our good quality and perfect service.

What we can provide:

1.1092,1575,1760,1880,2400,2640,2800,3200mm paper machine

2.pulp making equipments

3.paper making equipments

4.paper processing equipments

5.different kinds of spare parts

Certificate of hot selling 2400mm kraft paper production line

Our clients from different countries in the world:

1. Why we choose your company, what could you do for me?

We have established for 10 years and have the stable production experience.

We use the best steel to guarantee the products’ quality

Warranty: we make our machines one year warranty.

We will always give you heart to heart service

We always speak with facts and quality

2. How we visit your factory and what will be the procedure?

Our company located in Zhengzhou city,

Henan province, if you take plane, it need

s

about 2 hours from Guangzhou city, 1.5hours from shanghai city and 1 hour from

B

eijing.

we will pick you up from airport as well as the train station. We will take you to see our machine running in our Chinese clients' paper mill. Welcome you and your team to visit us at any time!

3. Could your engineer teach and train our worker and stay in our factory for long time?

Yes, we have very large engineer installation team,

they can train and teach your worker to operate paper machine,

but you should pay them salary.

4. How much water, electricity should I prepare for producing 1 ton finished paper?

(1) Clean water: 5M3

(2) Electricity: 250kw/h

5. Which kind of chemical I should prepare:

(1) Deinking agent

(2) Dispersing agent

(3) Bleaching agen t

6. How about your company orders?

(1) One set of paper machine line or part is supported by us

( 2) If we have urgent needs, we’ll do it for you

machine de recyclage wheat straw paper pulper machine karton roll production line, Coating white board paper making machine

machine de recyclage wheat straw paper pulper machine karton roll production line, Coating white board paper making machine

machine de recyclage wheat straw paper pulper machine karton roll production line, Coating white board paper making machine