- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Quarry

-

Usage:

-

Crushing Etc

-

Color:

-

Black

-

Advantage:

-

High Performance

-

Key words:

-

Jaw Plate

-

MOQ:

-

1 Piece

-

Packing:

-

Wooden Case

-

Diameter:

-

Provide Customized

-

Feature:

-

High Strengh

Quick Details

-

Weight (KG):

-

100

-

Place of Origin:

-

China

-

Product name:

-

Jaw Plate

-

Application:

-

Quarry

-

Usage:

-

Crushing Etc

-

Color:

-

Black

-

Advantage:

-

High Performance

-

Key words:

-

Jaw Plate

-

MOQ:

-

1 Piece

-

Packing:

-

Wooden Case

-

Diameter:

-

Provide Customized

-

Feature:

-

High Strengh

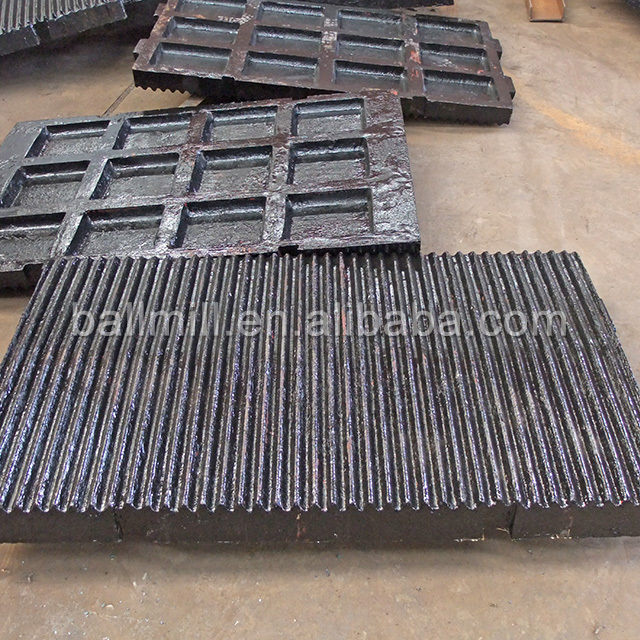

2. Use: wear parts for crushers in the quarry, mining, cement aggregate, recycling, shredding

and demolition fields. etc.

3. Certifications: ISO9001 &TS and CE certification.

4. Production quality testing: hardness testing, metallographic structure, machinery performance

testing,ultrasonic inspection, high frequency infrared carbon and surface analysis etc.

5. Competitive products: good quality with reasonable price.

6. Strong wear resistance and long life span, can be used in harsh environment and serious abrasion.

7. Professional: our factory has over 10 years working experience in casting and forging process and manufacture.

8. We can provide customized design according to our clients’ demands and also refine our products by our clients’ feedback.

|

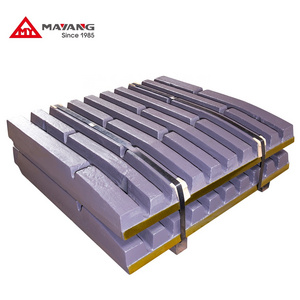

High manganese jaw plate |

|

|

Name |

Jaw plate, swing jaw plate, fixed jaw plate, toggle plate,movable jaw,fixed jaw,jaw crusher |

|

Material |

Mn13Cr2( M1 equivalent grades),Mn18Cr2(M2 equivalent grades) |

|

Control |

Spectrometer chemical analysis and control while producing |

|

Molding Process |

Water-glass sand casting or lost form casting |

|

Melting facility |

Medium frequency electric furnace |

|

Heat Treatment |

Anneal, quenching, tempering |

|

Quality Guarantee |

One year against manufacturing defeat |

|

Testing |

Hardness, flaw detector test |

|

Certificate |

ISO9001~2008 Passed; BUREAU VERITAS |

|

Application |

Cement firms, coal fired power plant ,mining firms ,metallurgy ,quarry firms |

Chemical Component of movable jaw plate:

|

Material |

Chemical Composition(%) |

Mechanical Property |

||||

|

C |

Si |

Mn |

Cr |

Ak/cm |

HB |

|

|

Mn13Cr2 |

1.1~1.4 |

1.7~2.2 |

12~15 |

1.7~2.2 |

>140 |

≤220 |

|

Mn18Cr2 |

1.1~1.4 |

1.7~2.2 |

17~19 |

1.8~2.2 |

>140 |

≤230 |

|

Type |

size(mm*mm*mm) |

weight(kg) |

tooth number |

|

100*600(swing plate) |

595*305*40 |

38 |

23 |

|

100*600(fixed plate) |

636*267*44 |

40 |

24 |

|

150*750(swing plate) |

750*480*72 |

115 |

24 |

|

150*750(fixed plate) |

805*430*60 |

100 |

25 |

|

250*1000(swing plate) |

1000*790*95 |

350 |

24 |

|

250*1000(fixed plate) |

1055*700*95 |

312 |

25 |

|

250*1200(swing plate) |

1200*790*95 |

420 |

29 |

|

250*1200(fixed plate) |

1255*700*95 |

375 |

30 |

|

150*250(swing plate) |

445*250*40 |

25 |

9 |

|

150*250(fixed plate) |

425*300*40 |

25 |

8 |

|

250*400(swing plate) |

725*400*60 |

100 |

10 |

|

250*400(fixed plate) |

635*460*70 |

80 |

11 |

|

400*600(swing plate) |

1000*600*75 |

228 |

11 |

|

400*600(fixed plate) |

960*660*75 |

216 |

12 |

|

500*750(swing plate) |

1330*750*130 |

540 |

8 |

|

500*750(fixed plate) |

1170*820*110 |

780 |

7 |

|

600*900(fixed plate) |

1240*960*150 |

735 |

9 or12 |

Description of Jaw Plate

jaw crusher wear parts is mainly used for crushing brittle materials, which stress usually less than 200Mpa, such as iron ore, gold ore, molybdenum ore, limestone and dolomite and etc. In the construction industry, it is mainly used for crushing limestone, cement clinker, gypsum and sandstone. Jaw crushers wear parts plate is the main wear parts of jaw crushers and need to withstand moderate impact while working. So the jaw plate requiring high impact toughness and wear resistance. The high manganese steel series material is the only choice for producing the jaw plates of primary jaw crusher and small jaw crusher .

General Description

Wear components for crushing processes are subjected to severe impact and high abrasion, requiring components made from impact resistant and abrasion resistant alloys.

We increase crusher availability through:

• Increased wear life

• Less on-going wear part maintenance

• Designs and tools for quicker change out

Features:

1). Material:

High manganese steel: Mn13%, Mn18%, Mn24%.

High chromium iron: Cr 20, Cr 24, etc.

2). Technological process:

Every model of jaw crushers in Shanlu is tested for shock, stress, strain, thermal loading, deformation, vibration and noise under a wide range of load conditions. The special processing techniques ensure that our jaw plate has leading performance.

3). Product quality testing:

High frequency infrared carbon & sulfur analyzer, Metallographic microscope, Machinery performance testing equipment, Hardness testing equipment, Ultrasonic inspection equipment.

4). Easy installation:

The anti-abrasion block is a semi-permanent part, which is easy for replacement.

Pre-service: Enthusiasm

1)We will reply to your enquiry within 24 hours.

2)All your inquiries will be well explained by our experienced staff.

Services during the sales: Servant

1)Pre-check and accept products ahead of delivery

2)The purchase contract has a certain reputation guarantee, provide you the perfect product to your hands.

After-sale services: Faithfulness

1)Send technicians to customer's local place for guiding the installation and adjustment, training operators.

2)In addition, our company provide one year warrantee to guarantee the machine runs consistently.