- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XINGXIONG

-

Model Number:

-

equipment accessorise part

-

Test:

-

Ut 100% / Element Testing

-

Special:

-

Cutting Tools, Measuring Tools

-

Cusoimized:

-

ODM/ OEM

-

Shape:

-

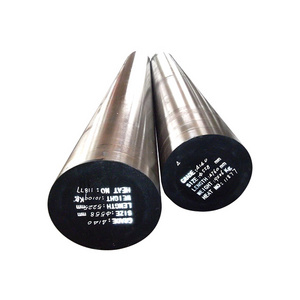

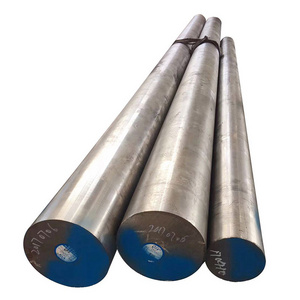

Round/Plate/Sheet/Flat Bar

-

Delivery Condition:

-

Hot Rolled/ Hot Forged

-

Business Way:

-

Wholesaler and Retail

-

Available Steel Shape:

-

Round Bar/Plate/Square

-

Our Service:

-

Cutting by Band-saw Machine /Peeling/ Grinding

-

Inspection:

-

100% Ultrasonic According to The Test Standards:Se

-

Technology:

-

Ef, Ef/Eaf+Lf+Vd, Ef/Eaf+ESR

Quick Details

-

Steel Grade:

-

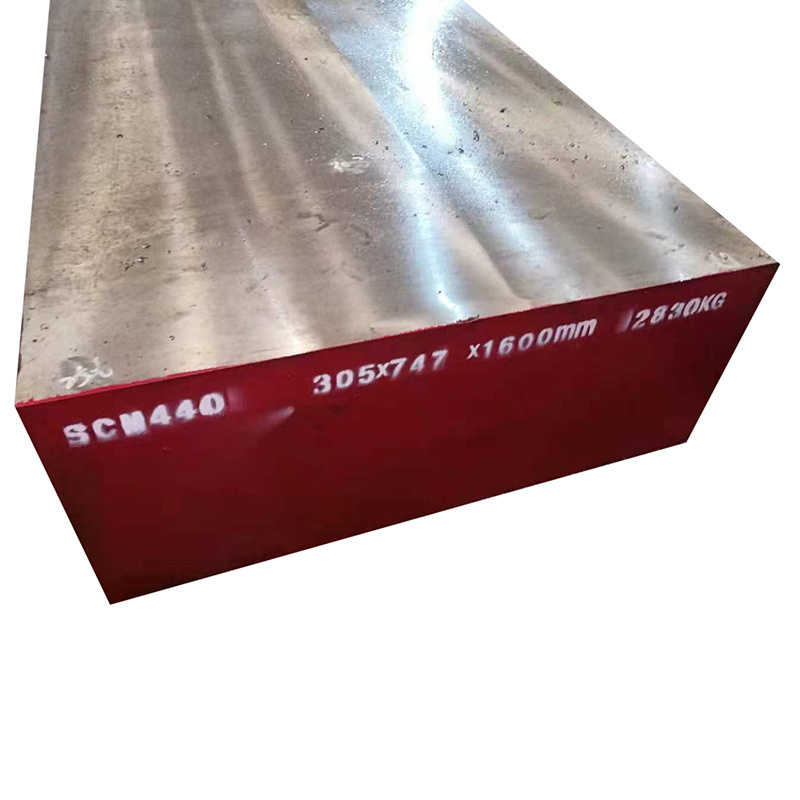

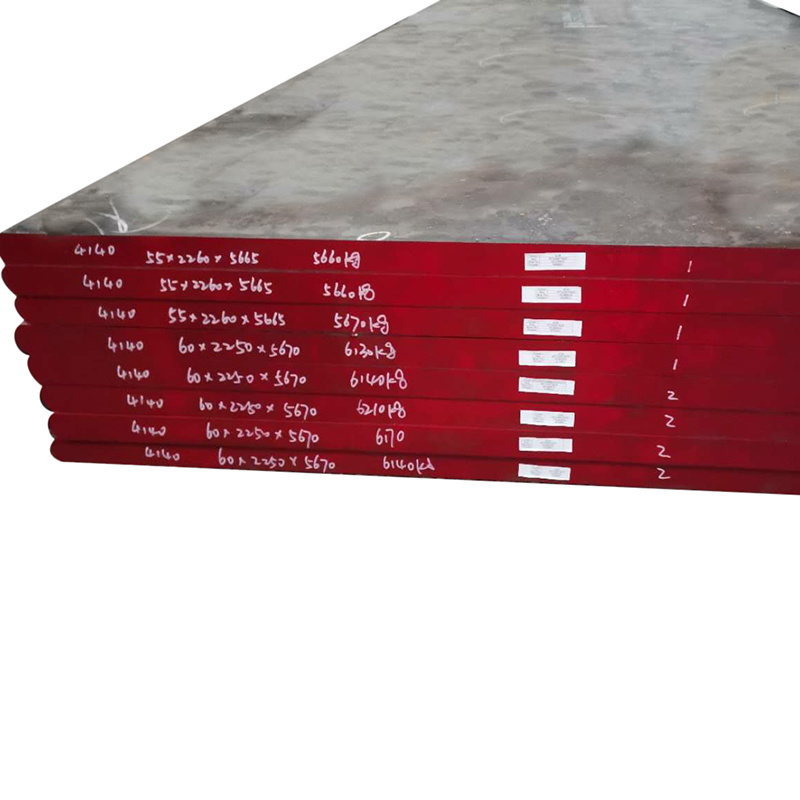

scr420 scr440 scm420 scm435 scm440

-

Tolerance:

-

±5%

-

Grade:

-

4140 SCM440 42CrMo

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XINGXIONG

-

Model Number:

-

equipment accessorise part

-

Test:

-

Ut 100% / Element Testing

-

Special:

-

Cutting Tools, Measuring Tools

-

Cusoimized:

-

ODM/ OEM

-

Shape:

-

Round/Plate/Sheet/Flat Bar

-

Delivery Condition:

-

Hot Rolled/ Hot Forged

-

Business Way:

-

Wholesaler and Retail

-

Available Steel Shape:

-

Round Bar/Plate/Square

-

Our Service:

-

Cutting by Band-saw Machine /Peeling/ Grinding

-

Inspection:

-

100% Ultrasonic According to The Test Standards:Se

-

Technology:

-

Ef, Ef/Eaf+Lf+Vd, Ef/Eaf+ESR

Tool and die steel 4140 42CrMo4 35CrMo 4135 scm435 scm440 1.7220 1.7225 long length steel flat bars

| Internation Steel Grade | |||

|

C HINA (GB) |

US (AISI) | JAPAN (JIS) | GERMANY ( W-NR ) |

| 20Cr | S120 | SCR420 | 1.7027 |

| 40Cr | S140 | Scr440 | 1.7035 |

| 20CrMo | 4118 | SCM440 | 1.7265 |

| 35CrMo | 4135 | 2234 | SCM435 |

| 42CrMo | 4140 | 2244 | SCM440 |

| 38CrMoAl | - | SACM645 | 1.8509 |

| 20CrMnTi | - | - | 1.8401 |

|

Structural steels are steels that meet specific strength and formability grades. Formability is expressed as elongation after the break of tensile test. Structural steels are commonly used for purposes such as load bearing, where the strength of the steel is an important design criterion.

Alloyed structural steel

This kind of steel, with suitable hardenability, after appropriate metal heat treatment, the microstructure is homogeneous sorbite, bainite or very fine pearlite, thus has higher tensile strength and showed (around 0.85), high toughness and fatigue strength, and low ductile to brittle transition temperature, can be used in the manufacture of section size larger machine parts. |

|||

Product Show:

| Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | P | S | Cr | Mo | |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.04 | 0.80-1.10 | 0.15-0.25 |

| 42CrMo | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.04 | 0.80-1.10 | 0.15-0.25 |

| SCM440 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.04 | 0.80-1.10 | 0.15-0.25 |

| 1.7225 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.04 | 0.80-1.10 | 0.15-0.25 |

| Product Parameter | |

| Product Name | tool and die steel 4140 42CrMo4 35CrMo 4135 scm435 scm440 1.7220 1.7225 long length steel flat bars |

| Steel Grade | equipment accessorise part |

| Specification |

Steel Round Bar: diameter 8mm – 3000mm

|

| Standard | AIS JIS DIN GB EN |

| HS Code | 72283024 72254000 720851100 |

| Forging |

Preheat the steel carefully, heat to 1150 oC – 1200 oC maximum, hold until temperature is uniform throughout the section.

Do not forge below 850 oC.Following forging operation the work piece should be cooled as slowly as possible. |

| Heat Treatment | Heat steels to 800 oC – 850 oC, hold until temperature is uniform throughout the section and cool in furnace. |

| Hardness | Anneal: ≤220HB Q+T: 12-22HRC |

| Application | ASTM alloy 4140 steel bar, flat or plate material can be used for as wide variety of applications where greater toughness and wear resistance is needed over lower carbon grades. Typical applications for 4140 tool steel uses include Components, Adapters, Arbors,strippers, holder blocks, mold bases, ejectors, back up and support tooling, fixtures, jigs, molds, cams, drill collars, Axle Shafts, Bolts, Crankshafts,stubs, couplings, reamer bodies, axles, shafting, piston rods, rams, hydraulic machinery shafts, gears, sprockets, gear racks, chain links, spindles, tool bodies, tool holders, tie rods, Connection Rods, Chuck Bodies, Collets, Conveyor Pins & Rolls, Ejector Pins, Forks, Gears, Guide Rods, Hydraulic Shafts & Parts,Lathe Spindles, Logging Parts, Milling Spindles, Motor Shafts, Nuts, Pinch Bars, Pinions, Pump Shafts,boring bars,tracks, slides, wear strips or parts, forming dies, brake dies, trim dies, bolsters, machinery parts and components, etc. |

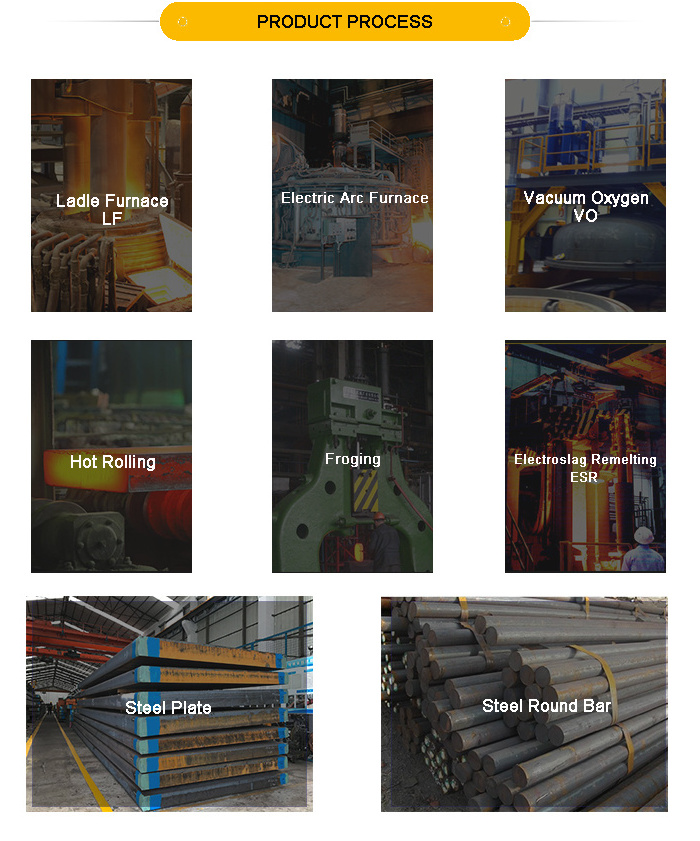

1.Steel Smelthing: (Ladle furance / Electric Arc Furnace / Vacuum oxygen ).

2.Steel Ingot: (Ingot Rolling / electroslag remelting furnace).

3.Steel Round Bar: (Steel Round Bar / Steel Plate ).

4.Finished: (Cutting / Milling / Surfacing Griding / Heat treatment / Round Steel Bar Turing).

MAINLY SALE GRADE OF STEEL:

PLASTIC MOULD STEEL: 1.2311, 1.2312, 1.2738, P20, 1.2083, 1.2316, NAK80, P40, 1.2738HH

HOT WORK MOULD STEEL: 1.2344, SKD61, H13, H11, FDAC, 8407

COLD WORL MOULD STEEL: SKD11, D3, SKS3, 1.2080, 1.2379, CR12MOV, O1, D2

STRUCTURAL ALLOY STEEL: 4140, 20CR, 40Cr, 35CrMo, 42CrMo, 38CrmoAi, SCM440, SCM420, 1.7225

CARBON STEEL &: Q235, Gcr15, S45C, S50C, S55C

Cutting: Horizontal band saw cutting / Vertical band sawing machine

Milling:CNC surface grinding machine, NC side boring machine, Band saw,

CNC double head machine,Vertical Band saw, CNC milling machine,

Double alloy saw blade, wireless remote control crane, Magnetic chuck

Inspection: Hardness / Spectral Analysis / Ultrasonic testing, etc.