- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TZ

-

Voltage:

-

220/300/400/440V

-

Dimension(L*W*H):

-

According to Specific Models

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

1000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Conveying system

-

Work efficiency:

-

<50m3/H

-

Temperature tolerance:

-

150°

-

Working mode:

-

circulating transport

-

Work Principle:

-

PLC automatic control

-

medium:

-

dry dust

-

granularity:

-

<3mm

Quick Details

-

Power:

-

4KW

-

Warranty:

-

1 Year

-

Width or Diameter:

-

900mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TZ

-

Voltage:

-

220/300/400/440V

-

Dimension(L*W*H):

-

According to Specific Models

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

1000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Conveying system

-

Work efficiency:

-

<50m3/H

-

Temperature tolerance:

-

150°

-

Working mode:

-

circulating transport

-

Work Principle:

-

PLC automatic control

-

medium:

-

dry dust

-

granularity:

-

<3mm

Pneumatic conveying system conveying pump equipment for cement silo

Dense-phase pneumatic conveying system is specially applied to a variety of dust long-distance sealed transport; the adaptive conveying distance equivalent is 50-500 meters, transport materials: fly ash, lime powder, cement, aluminum powder, mineral powder, saw dust, straw and so on. The equipment is simple, with small occupation area, it can make full use of space, and pipelines can be flexible layout, so that the configuration of the plant equipment will be more rational. System configuration is complete, PLC set control the entire system, fully automated operation, easy maintenance.

Characteristic

---Using compressed air as primary energy sources

---Solving the stratification of powder and granules

---The filters made of Ti will never be jammed and be abraded

---Eliminate the static electricity

---Made of nontoxic and corrosion resistant materials

---Leakage free capsule, to prevent cross contamination

---Intelligent control and high automation

---Materials are not adhering to the inner surface of the conveyor

---Modular structure, easy to clean and dismantle

---Small and light ,easy to install

---Low noise and free from vibration

---Energy saving and low running cost.

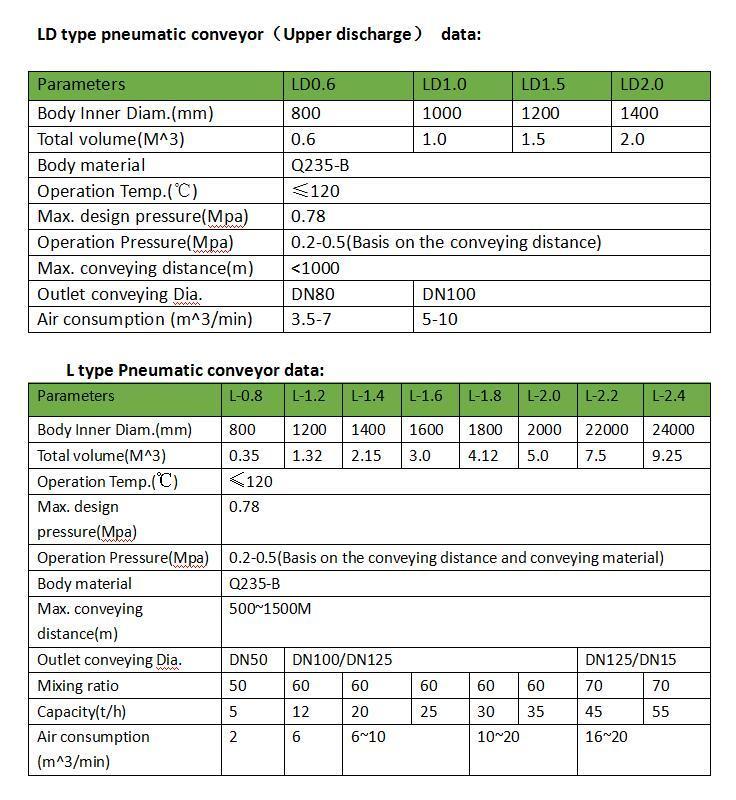

Parameters of Pneumatic Conveyor for reference:

1. Dense Phase Fly Ash Handling System are much better suited to powder handling than mechanical conveyors because the conveyance channels used in pneumatic conveyors are completely enclosed.

2. Dense Phase Fly Ash Handling System are used for materials handling and transportation in a wide range of industries. Unlike many mechanical conveyor designs, pneumatic conveyors can be designed to move products between floor levels and around difficult angles.

3. The whole system is composed of compressed air source,storage pump,control cabinet,conveying pipe and ash storage.

4.This system are suit for variety material transportation ,eg:fly ash,kiln dust, cement, etc dry powder material(moisture content <5%).