- Product Details

- {{item.text}}

Quick Details

-

Length:

-

According to customer requirements, From 10mm to 10000mm for ball screw

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Matech

-

Item Name:

-

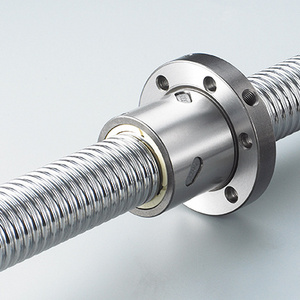

Matech Factory Wholesale 8mm Ball Screw SFU 0802 0601 With Nut

-

Grade:

-

C7, C5, C3 for ball screw

-

Application:

-

CNC machine, 3D printing machinery, chemical machinery and so on

-

Nut type:

-

Single or double nuts

-

Production Process:

-

Cold Rolling, CNC Grinding, Whirling Milling

-

Package for ball screw:

-

Multilayer wooden box/pallet, with big plastic bag inside

-

Lead Time:

-

3 days for sample order, bulk order need to be negotiated

-

Service:

-

Custom service, supply inspection report

Quick Details

-

Weight (KG):

-

1

-

Marketing Type:

-

customized products

-

Material:

-

steel,or customized, Bearing steel, alloy steel, GCr15 and so on

-

Length:

-

According to customer requirements, From 10mm to 10000mm for ball screw

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Matech

-

Item Name:

-

Matech Factory Wholesale 8mm Ball Screw SFU 0802 0601 With Nut

-

Grade:

-

C7, C5, C3 for ball screw

-

Application:

-

CNC machine, 3D printing machinery, chemical machinery and so on

-

Nut type:

-

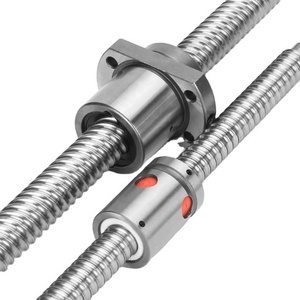

Single or double nuts

-

Production Process:

-

Cold Rolling, CNC Grinding, Whirling Milling

-

Package for ball screw:

-

Multilayer wooden box/pallet, with big plastic bag inside

-

Lead Time:

-

3 days for sample order, bulk order need to be negotiated

-

Service:

-

Custom service, supply inspection report

Product Description

|

Item Name

|

Matech Factory Wholesale 8mm Ball Screw SFU 0802 0601 With Nut

|

|

Material

|

Bearing steel, alloy steel, GCr15 and so on

|

|

Grade

|

C7, C5, C3 for ball screw

|

|

Length

|

From 10mm to 10000mm for ball screw with external return tube, can be customized based on customers requirement

|

|

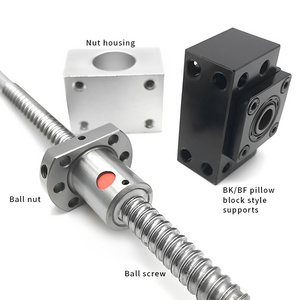

Flange Type

|

No cutting, Single Cutting, Double Cutting

|

|

Nut type

|

Single or double nuts

|

|

Produce Code

|

Ground, Rolled for ball screw

|

|

Production Process

|

Cold Rolling, CNC Grinding, Whirling Milling

|

|

Feature

|

High stiffness

High efficiency High load & speed High Precision & low noise |

|

Application

|

CNC machine, 3D printing machinery, chemical machinery, woodworking machinery, engraving machines, window machines, high speed machinery, semi-conductor equipment, robot, railways, automation applicationand etc

|

|

Our Services

|

Custom ball screw based on drawings or samples

|

|

Delivery Time

|

3 days for sample order, bulk order need to be negotiated

|

Products shown here are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within MATECH group of companies.

MATECH policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

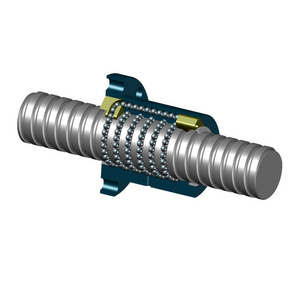

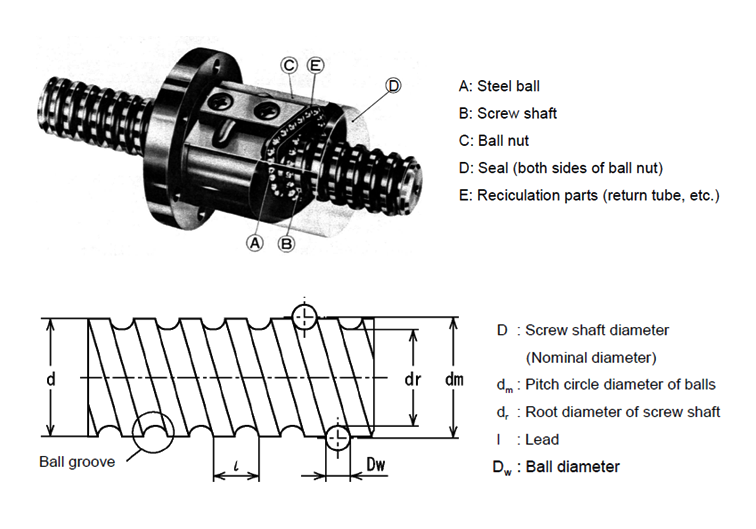

Ball screw according to GB classification there are P class and T class, that is, transmission class and positioning class, the accuracy level has 1, 2, 3, 4 ..... Several kinds, foreign products generally do not distinguish transmission or positioning, all to C0 ~ C10 or specific values.

In general, general-purpose machinery or ordinary CNC machinery selected C7 (any 300 stroke within the positioning error ± 0.05) or below, high-precision CNC machinery selected C5 (± 0.018) above C3 (± 0.008) below, optical or detection machinery selected C3 above.

Ball screw bearing specifications selection

(1) Determine the positioning accuracy;

(2) Determine the lead of the ball screw bearing by the motor and the speed requirement;

(3) Check the nut size to determine the stroke and related data of the shaft end of the screw bearing;

(4) Determine the average axial force and speed by load and speed distribution (acceleration and deceleration);

(5) Determine the pre-pressure from the average axial force;

(6) Determine the dynamic load rating by life expectancy, axial load and speed;

(7) Determine the outer diameter of the screw bearing and the nut form by the basic dynamic load rating, lead, critical speed, and DmN value limit;

(8) The outer diameter, nut, preload, and load determine the rigidity (machine design);

(9) Ambient temperature, total length of the nut to determine the thermal variation and cumulative lead;

(10)Screw bearing rigidity, thermal variation position to determine the pre-tension;

(11)Maximum machine speed, temperature rise time, and screw bearing specifications determine motor drive torque and specifications.

↓

↓

↓

↓

↓ ↓

Click here to get a free quotation!

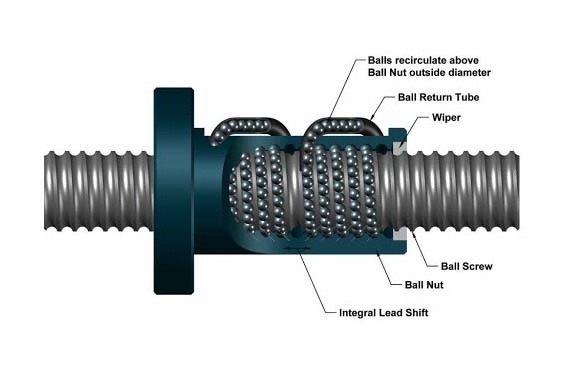

What is the difference between a lead screw and a ball screw?

The basic difference between lead screws vs ball screws is that a ball screw uses ball bearings to eliminate the friction between the nut and screw and lead screws.

Lead screws use deeper helical threads and a mating nut, which is usually made of a polymer composite or bronze.

Heavy stiffness:

Optimized screw profile and structure design. Heavy load: Multi-load ball distribution design. Low vibration noise: Using the best slender ratio and high-speed circulation to lower noise.

Constant temperature:

The efficient heat transfer can restrain the thermal deformation and improve the stability. Environment friendly: Optional self-lubricant function can reduce the lubricant consumption and to diminish the environment pollution caused by lubricant discard. It also solves the problem that lubricant thickens unevenly by deformation of oil film in spiral path.

Our Advantages

Our company has strong R&D capability and develops many new products every year. In production, we strictly follow the ISO 9001 quality system to control quality and arrange production:

1. Don't accept defective, strict inspection of supplier's raw materials.

2. Don't manufacture defective, the production process is strictly controlled. For all products, the workers are strictly

self-inspected on each machining process, and the quality inspectors do a regular inspection and spot inspection.

3. Don't transferring defective, the defective products found in the previous process shall never be allowed to be transferred to the next process. Before shipment, the finished products shall be inspected again, and if any quality problems are found,and the products shall be reworked or rejected according to the relevant requirement.

Core Competence

1. Over 15 years professional manufacture experience. → We know better to your needs.

2. One-stop Service of Custom mold design from Initial drawing design, Material selection assistance, Mold structure/Mold flow

analysis, Trial & mass production to Final assembly & shipment. → To ensure you get finished products with good assembly function.

3. High skilled and well-trained working team under good management environment. → To make sure high quality of your products.

4. Large and strong production capacity. → To meet your high demands very well.

5.Best price based on same quality requirements. →To help your project with most economical solution.

6. We have very strict quality control process included IQC/IPQC/FQC/OQC. → To deliver the qualified products for you.

7.Reliable Package & flexible in-time delivery. →To guarantee the product are well received in your side.

8. 24 hours on-line service with quick response. → To support your any inquiry or question.

Technical Support:

Shanghai Matech is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID

WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples

or just an idea. Dural control of standard products and OEM products.

Quality Control:

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Shanghai Matech is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID

WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples

or just an idea. Dural control of standard products and OEM products.

Quality Control:

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Hot Searches