- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan

-

Brand Name:

-

Wanlong

-

Voltage:

-

220V,380V

-

Dimension(L*W*H):

-

1000*800*1300mm

-

Weight (KG):

-

220 kg

-

Name:

-

Cement Brick Block Making Machine

-

Raw material:

-

Sand

-

Block Type:

-

Hollow Concrete Brick Machine

-

Model:

-

qmj 2-45

-

Brick type:

-

Hollow Brick Concrete Brick Hole Brick

-

Keywords:

-

Automatic Cement Block Moulding Machine

-

Products:

-

Concrete Interlock Blocks

-

Advantage:

-

Low Investment

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Cement, Sand, Crushed Stone, Fly Ash,Pigment, Water

-

Production Capacity (Pieces/8 hours):

-

Other, 4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan

-

Brand Name:

-

Wanlong

-

Voltage:

-

220V,380V

-

Dimension(L*W*H):

-

1000*800*1300mm

-

Weight (KG):

-

220 kg

-

Name:

-

Cement Brick Block Making Machine

-

Raw material:

-

Sand

-

Block Type:

-

Hollow Concrete Brick Machine

-

Model:

-

qmj 2-45

-

Brick type:

-

Hollow Brick Concrete Brick Hole Brick

-

Keywords:

-

Automatic Cement Block Moulding Machine

-

Products:

-

Concrete Interlock Blocks

-

Advantage:

-

Low Investment

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Video technical support

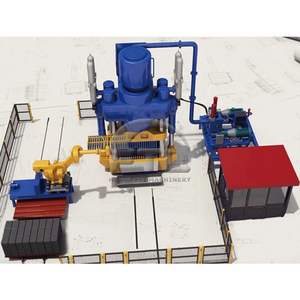

Product description

Factory price electric 2-45 solid interlcoking paving floor recycled plastic 100 ton maxi brick making machine

Working principle of concrete block brick molding making machine

This type of brick making machine is developed by combining the advantages of several other manual brick making machines. The machine is designed with reasonable structure and advanced technology. Four vertical axis guidance, upper die push and pull, automatic scraping, reducer lifting mode. Thereby increasing block forming speed, increasing block density and reducing raw material consumption. It Only 1 people are needed for production and transportation. , and the investment is low, so this manual hollow block machine is very suitable for factories or family businesses.

1. Electric motor Inclined push type

2. Electric motor Straight push type

3. Diesel engine Straight push type

Manual hollow block making machine is a miniature block machine of high quality, its main characteristic is saving electricity and saving work force, and can produce hollow blocks on cement floor without any pallet, especially suitable for small factories.

|

Basic parameters of QMJ 2-45 brick making machinery

|

|

|

|

|

||||

|

Model

|

QMJ2-45

|

|

|

|

||||

|

Power

|

1.5KW

|

|

|

|

||||

|

Vibrating Method

|

Mould vibration

|

|

|

|

||||

|

Molding cycle

|

45s

|

|

|

|

||||

|

Dimension(L*W*H)

|

1000*800*1300mm

|

|

|

|

||||

|

Host machine weight

|

220kg

|

|

|

|

||||

Feartures of QMJ2-45 brick making machine

1. Multi function

Qmj2-45 concrete block machine can produce various hollow blocks, solid blocks, pavers and curbs by changing molds.

2. Strong and durable, high density brick

Adopt new technology mold vibration mode to make brick., which makes the working state of brick machine more stable and efficient, and produces bricks with better quality, higher density and higher strength.

3. High quality mould

Precision wire cutting technology and carburizing treatment technology ensure longer die life.

4. Standardization

All materials and spare parts are selected according to international CE standard to ensure stable operation.

5.Spare parts

Follow the machine shipment, we supply suitable wearing parts, the after-sales services will be faster.

6.Low investment and high return.

|

Item

|

Size

|

Quantity

|

Cycle molding

|

10 hours

|

|

Hollow brick

|

400*200*200mm

|

2pcs/mould

|

40-45s

|

1500pcs

|

|

Hollow brick

|

400*150*200mm

|

3pcs/mould

|

40-45s

|

1750pcs

|

|

Hollow brick

|

400*120*200mm

|

3pcs/mould

|

40-45s

|

2250pcs

|

Why Choose Us

Our Company

FAQ

1.How about the quality of machines?

Our machines adopt advanced technology. Moreover, we carry out strict supervision during production and make sure every finished product with high quality.

2.About the delivery time.

Generally, it will be about 10-15 working days after receive your deposit, which also will be on basis of your order.

3.About warranty.

We provide 12 months for warranty.

4.Which kind of payment is available for us?

The advance deposit paid by T / T is 30%, and the balance before t / T loading is 70%. You can also choose other trading methods.

5.What kind of products we can supply ?

Auto concrete brick making machine, Auto hydraulic brick making machine, Free pallet automatic block forming machine,

Concrete,mixer, Batching machine, Stacker, Cuber, etc.

6.How to make different size and shape brick by one machine?

By changing mould it can produce all types of standard building blocks.

Our machines adopt advanced technology. Moreover, we carry out strict supervision during production and make sure every finished product with high quality.

2.About the delivery time.

Generally, it will be about 10-15 working days after receive your deposit, which also will be on basis of your order.

3.About warranty.

We provide 12 months for warranty.

4.Which kind of payment is available for us?

The advance deposit paid by T / T is 30%, and the balance before t / T loading is 70%. You can also choose other trading methods.

5.What kind of products we can supply ?

Auto concrete brick making machine, Auto hydraulic brick making machine, Free pallet automatic block forming machine,

Concrete,mixer, Batching machine, Stacker, Cuber, etc.

6.How to make different size and shape brick by one machine?

By changing mould it can produce all types of standard building blocks.

Hot Searches