- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

IM-08

-

Product Name:

-

plastic injection

-

Plastic Material:

-

ABS/PP/PS/PE/PVC/PA6/PA66/...

-

Surface treatment:

-

Polishing, Texture, Paning etc.

-

Size:

-

According to the drawing

-

Usage:

-

According to design

-

Feature:

-

Sufficient inventory, Sustainable

-

Name:

-

Make Plastic Injection Mould

-

OEM:

-

customizable

-

Mould material:

-

718/738/NAK80/S136/718H/P20/...

Quick Details

-

Processing Service:

-

Moulding, Cutting, CNC, Vacuum forming, Injection, Assembly, Spray Paint, CNC carving

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Flourish Legend

-

Model Number:

-

IM-08

-

Product Name:

-

plastic injection

-

Plastic Material:

-

ABS/PP/PS/PE/PVC/PA6/PA66/...

-

Surface treatment:

-

Polishing, Texture, Paning etc.

-

Size:

-

According to the drawing

-

Usage:

-

According to design

-

Feature:

-

Sufficient inventory, Sustainable

-

Name:

-

Make Plastic Injection Mould

-

OEM:

-

customizable

-

Mould material:

-

718/738/NAK80/S136/718H/P20/...

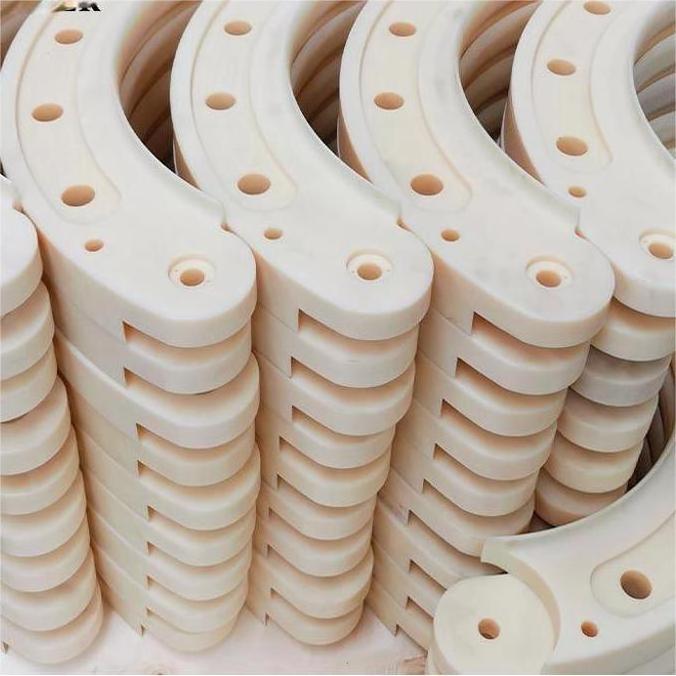

Products Description

|

Design & Size

|

Customized according to the customer's drawing or according to the sample prototype.

|

|||

|

Material

|

PC,PMMA,PETG,PET,ABS,PP,PE,PVC,HDPE

|

|||

|

Thickness

|

From 1mm to 15mm or customized etc.

|

|||

|

Feature

|

Environmentally friendly, Durable, Safe, High quality, Fast delivery, Low MOQ

|

|||

|

Main Process

|

Design development, mold making, sample discussion, material fabrication, vacuum forming, 5/3 axis CNC cutting, assembly,

trimming, scraping, polishing, screen printing, painting, quality inspection, packaging, export shipment.

|

|||

|

Color/Logo

|

OEM/ODM

|

|||

|

Packaging

|

EPE,Polyfoam,carton,wooden box or according to customer's requirement.

|

|||

|

Payment Method

|

T/T L/C,Credit Card, Paypal,West Union,etc

|

|||

|

Sample time

|

15-20days

|

|||

|

MOQ

|

50PCS

|

|||

|

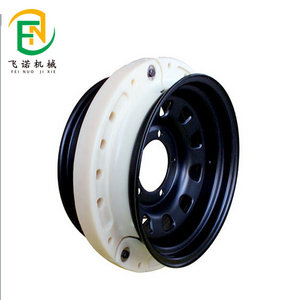

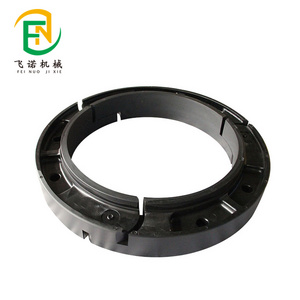

Applications

|

Agriculture, auto parts, advertising display racks, TV backshells, cosmetic storage boxes, turnover trays, acrylic products,

sanitary ware, medical facilities and other mechanical parts housings, etc.

|

|||

|

Vacuum Forming Technology

Vacuum molded housings offer several advantages such as fast production cycles and design freedom. The process enables rapid realization of complex shapes and contours, providing designers with greater creative freedom. In addition, the light weight,excellent surface quality, and low waste generation of vacuum formed housings have led to a wide range of applications in automotive, advertising, toy manufacturing, and machinery housings.

|

Product Case

Material Texture

Customized Materials

FAQ

|

Q1:What kind of products can our company provide for you?

A1:Accessories such asmachinery and equipment shells, auto interior and exterior parts, planting trays, TV rear shells and savings.

Q2: How long does it take to get samples?

A2:Depending on your project requirements, the production time usually takes 15 to 20 days.

Q3: How do I enjoy the OEM service?

A3:After receiving your design drawings or original samples, we will give you some technical suggestions and quotation at first, and after you agree, we will produce for you.

Q4:Can you make processed parts according to our samples?

A4:Yes, we can measure and make drawings of the machined parts according to your samples.

Q5. How can we guarantee the quality?

A5:We have a perfect self-inspection system, and every batch of products will be professionally checked for quality before shipping. Before mass production, we will arrange a pre-production sample and confirm with you that there is no error before arranging mass production.

|

Hot Searches